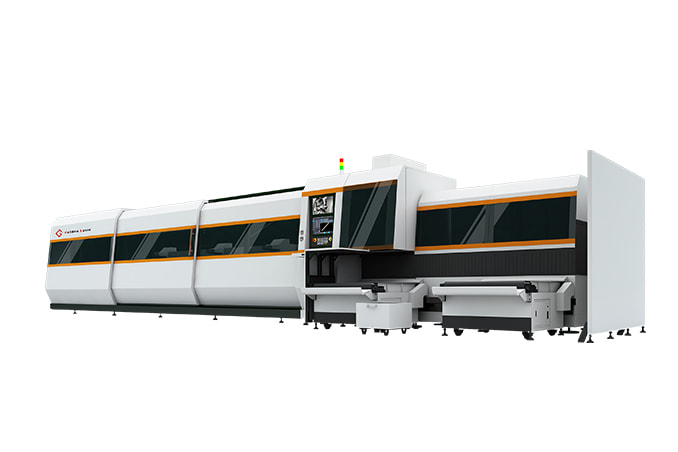

| Model number | i 25-3D / i 25A-3D / (P2560A-3D) |

| Tube length | 6000mm, 8000mm optional |

| Tube diameter | 20-250mm / 20-350mm |

| Laser Head | Imported 3D Tube Laser Head BLT / Golden Laser 3D head for Choice |

| Laser source | Imported fiber laser resonator IPG / N-Light / China Laser Source Raycus / Max |

| Servo Motor | Yaskawa Bus Motor |

| Laser source power | 3000w 4000w 6000w optional |

| Position accuracy | ±0.05mm |

| Repeat position accuracy | ±0.03mm |

| Rotating speed | 130r/min |

| Acceleration | 1.2G |

| Max Weight for Single Tube | 225kg (Φ200mm*8mm*6000mm) |

| Cutting speed | depend on material, laser source power |

| Electric power supply | AC380V 50/60Hz |

| Auto tube Feeder | i 25A-3D including the auto tube feeder |

3D 5axis Fiber Laser Tube Cutting Machine - with Rotary 3D Laser Cutting Head for Tube Bevel Cutting... Suit for different shape groove bevel cutting on metal tubes, the tube outer diameter can be 20-350mm, metal tube length 6meter. With Auto tubes bundle loading system for automatic tube laser cutting process.

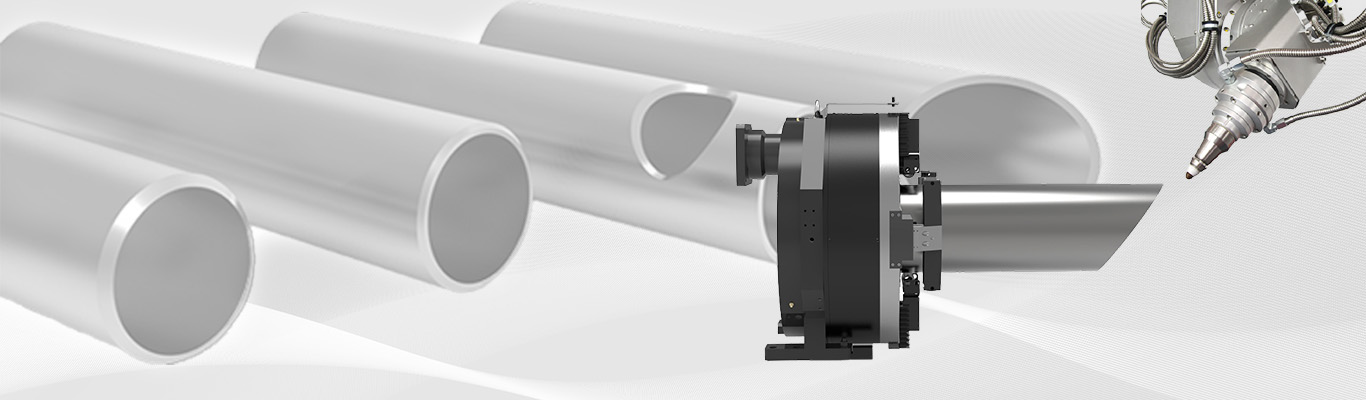

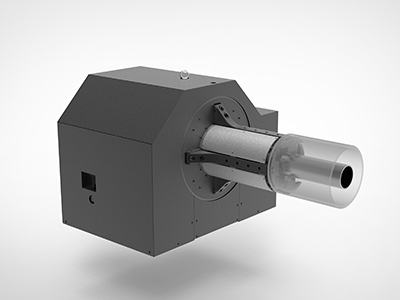

Rotary 3D Laser Cutting Head Imported from Germany

Groove Cutting Ability ( Beveling Ability)

Excellent Groove Cutting Ability of the Pipe End Surface

Make the Pipe Splicing More Beautiful After Cutting.

Avoid Cutting the Weld Seam of The Pipe Itself (No Breaking of The Welding Tubes).

Realize the Groove cutting of Various Shapes, such as Round holes and Square holes on The Pipe Surface.

Ability to Perfectly Match the Penetration Splicing Between the Tube and The Finished Cutting.

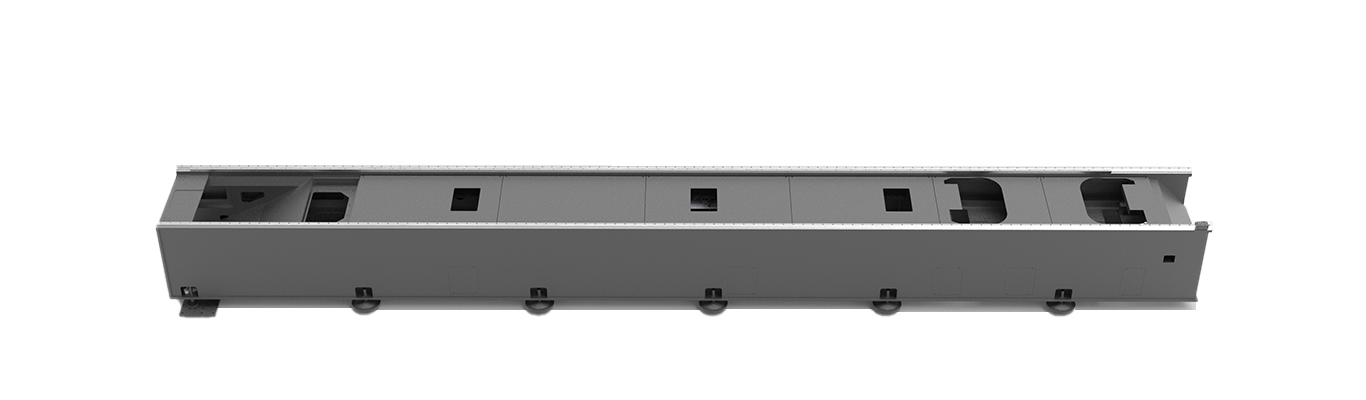

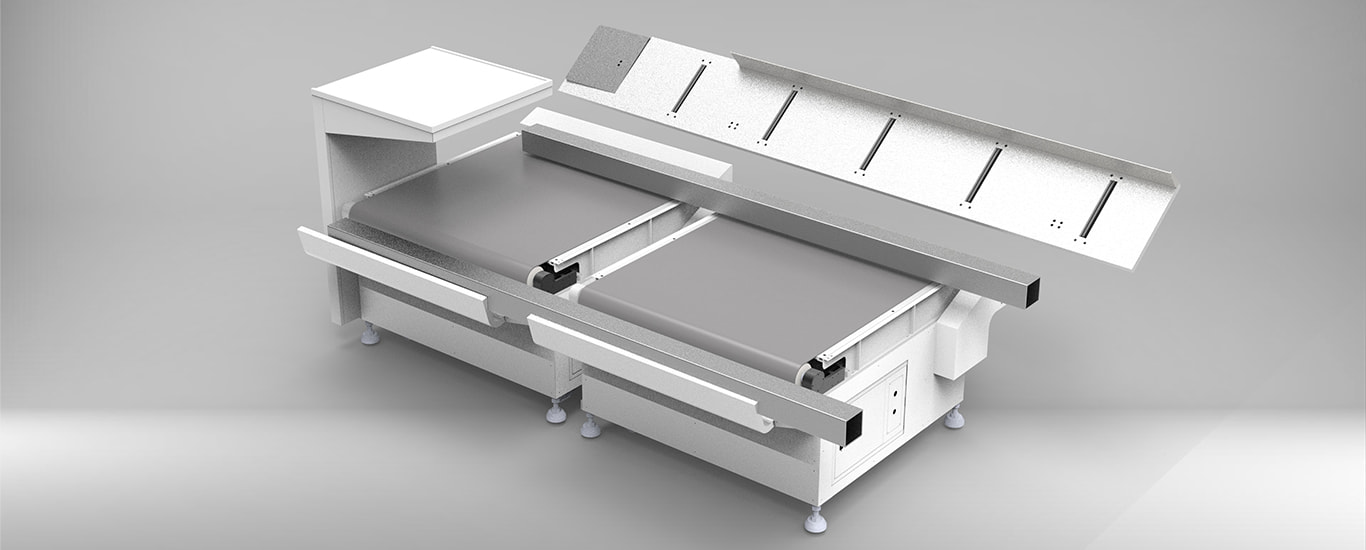

Full-thickness Steel Plate Welding Machine Structure:

The machine body is stable, has a long service life, and is not easily deformed.

The thickness of the welding plate of the machine structural is up to 25 mm,

The single machine weighs up to 7 tons.

Floating Tubes Support System

The Latest Floating Support System is Adopted.

Servo Variable Diameter Wheel Support Device

Two auxiliary feeding and centering devices are arranged close to the front chucks to ensure the center of the tube

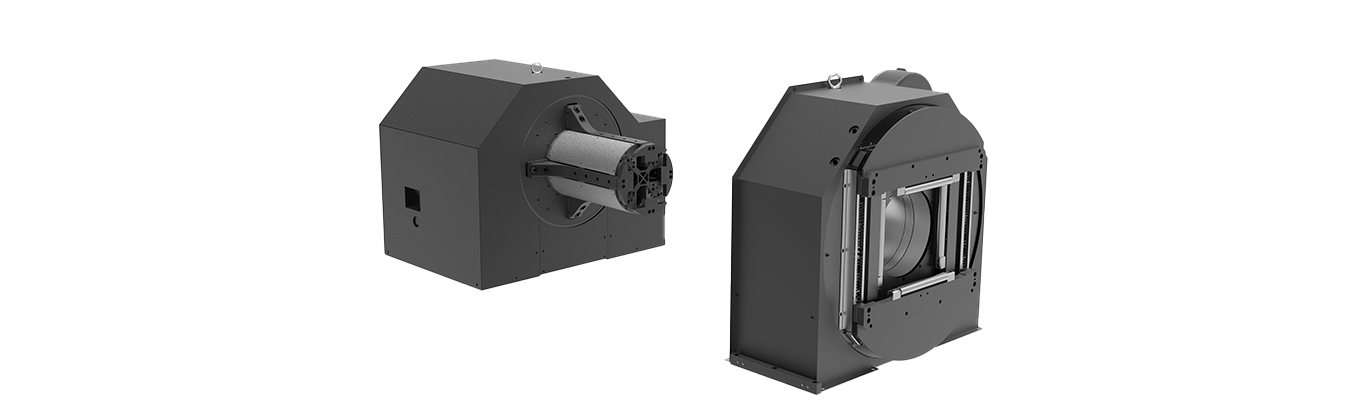

Professional Self-centering Pneumatic Chuck Clamping System

The chuck is made of high-bearing steel material, with high sealing performance and good dynamic performance.

The intermediate chuck is innovatively embedded in a casting frame and integrated with the main body of the machine structure.

No need to adjust the jaw position for full stroke clamping.

The maximum clamping force of the chuck is up to 300kg, which is 25% higher than the previous generation of chucks.

The maximum speed can reach 130r/min.

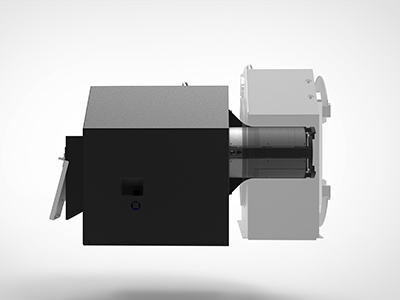

Tail Dust Extraction

Dust and Smoke Separation

The precisely designed dust extraction duct effectively captures and extracts the dust and smoke accumulated at the rear clamping claw during the cutting process. After being processed by the high-efficiency filtering device, the dust and fine slag waste are accurately separated and discharged into the collection box through the discharge window at the rear for subsequent processing.

This not only ensures the long-term unobstructed dust extraction duct, but also greatly improves the safety and environmental protection of smoke purification.

Barrel Structure

Shorter Tube Tail

The rear clamp adopts a cannon-barrel structure design and is matched with high-strength clamping claws, which not only enhances the rigidity of the clamping, but also ensures stability and precision during high-speed cutting.

In addition, this design allows the rear clamp to easily penetrate the interior of the front clamp, maximizing the proximity to the laser cutting head, thereby achieving precise cutting of shorter tail materials and improving material utilization.

Flexible Pipe Clamping

Stable and Reliable

The unique serrated surface processing of the jaws significantly enhances the clamping adhesion between the pipe and the material, effectively preventing the pipe from slipping during the clamping process, and improving the accuracy and safety of cutting.

The rear clamping part supports two flexible pipe clamping modes. For small-diameter pipes, the external clamping method is used to ensure uniform and stable clamping force; for large-diameter pipes, the external support mode can be selected to make the clamping more stable and reliable.

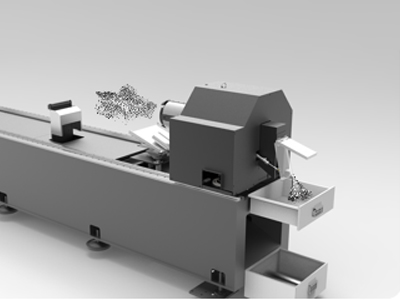

Automatic Tube Material Receiving Device

The Auto Bundle Loading System

-Improve Production Efficiency

The Automatic Loading System Realizes the Automatic Continuous Production, is Especially For Mass Production Demand.

Tubes auto feeding system is suitable for 800*800mm bundle pipe loading. With an automatic measure function to ensure loading the right pipe without any mistake. The alarm warning system reminds the operator during the whole production, PLC controller of the automatic loading system easy to adjust according to the detail processing demand, Autoloading, Your best choice for mass bevel cutting machine for pipes...

3D Tube Laser Cutting Machine Video

_

With Beveling Welding Result

Samples Compare

_

Between 3D Pipe Bevel Cutting Machine for Tubes and Normal 2D Laser Tube Cutting Machine for Pipes

3D Laser Tube Cutting Result

Compare With

2D Laser Tube Cutting Result

Material & Industry Application

3D Laser Tube Cutting Application:

Mainly for tube angle cutting, 45-degree angle cutting for Channel Steel, I-beam and so on.

3D laser tube cutting widely used in heavy machinery, Shipbuilding, construction industry and so on.

Machine Technical Parameters

Related products

-

P30120

12m Length Stainless Steel Metal Pipe Tube Laser Cutting Machine P30120 -

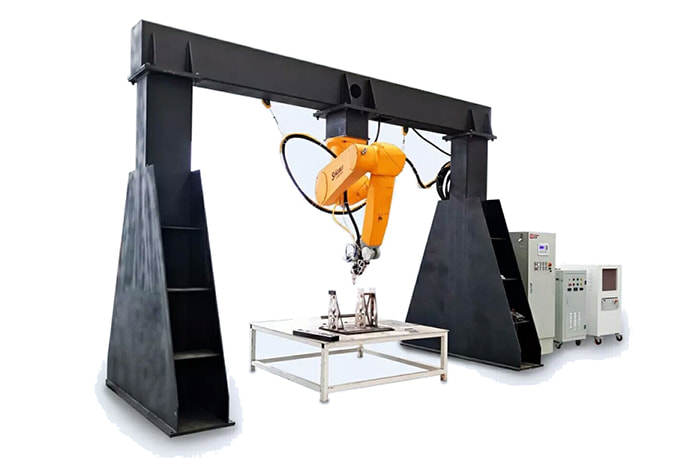

ABB X2400D/X2400L / Staubli XR160L

Robotic Arm Fiber Laser 3D Cutting Machine -

ABB 1410

3D Robotic Arm Laser Welding Machine