Revolutionizing Metal Formwork Production with Fiber Laser Cutting Machine Technology

As we know, formwork production is a crucial yet often time-consuming process in the construction industry. There are many different materials and types of formwork to meet the different structure-building demands. Consider the environmental protection and long-term use requirements. Steel formwork and aluminum formwork are much more popular.

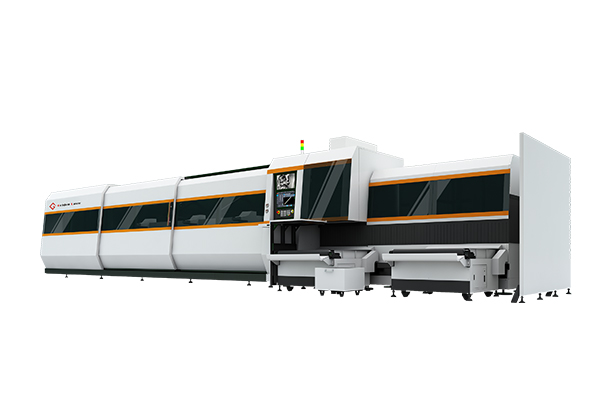

How to improve the steel and aluminum formwork processing efficiency and ensure quality? Fiber Laser Cutting Machine gives the best solution.

Fiber laser technology offers remarkable precision and quality. The highly focused laser beam can cut metal formwork materials with higher accuracy than traditional plasma and line-cutting machines and a better smooth cutting edge, which ensures better quality welding results. It means these complex shapes and designs previously difficult or labor-intensive to produce can now be achieved easily.

Digital Fiber laser cutting machine enables easy customization formwark. Construction projects often have unique requirements, and formwork supplier production needs to be tailored accordingly. With fiber laser cutting machines, custom designs can be quickly programmed and produced, allowing construction teams to implement innovative architectural concepts. For example, in architectural projects that require unique and intricate formwork for concrete structures, fiber laser-cut formwork can meet the exact specifications and customize design.

The speed of production is another significant advantage. Fiber lasers can cut through metal materials at a much faster rate compared to traditional cutting methods. Especially the high power fiber laser cutting machine 20000W Fiber laser cutting machine more and more popular in mass cutting over 20mm thickness metal sheet. This rapid cutting ability translates into shorter production cycles, allowing construction projects to move forward more quickly. Contractors can meet tight deadlines without sacrificing quality.

In terms of maintenance, the using life of fiber laser over 100000 hours, fiber laser cutting machines are relatively easy to maintain. This reliability means less downtime in production, ensuring a continuous supply of formwork for construction sites.

Moreover, fiber laser cutting machines reduce material waste. The precise cutting ensures that the material is used optimally, minimizing scrap. This not only saves costs but is also environmentally friendly. In a world where sustainability is increasingly important, the reduction of waste in metal formwork production is a significant benefit.

In conclusion, fiber laser technology enhance steel formwork production. Its precision, speed, easy maintenance and material - saving features make it an indispensable tool for modern construction. By adopting this technology, construction companies can enhance their productivity and competitiveness while delivering high - quality projects.

Want to know more about fiber laser cutting machine solutions in the formworks factory industry? Welcome to contact Golden Laser fiber laser cutting machine team.