|

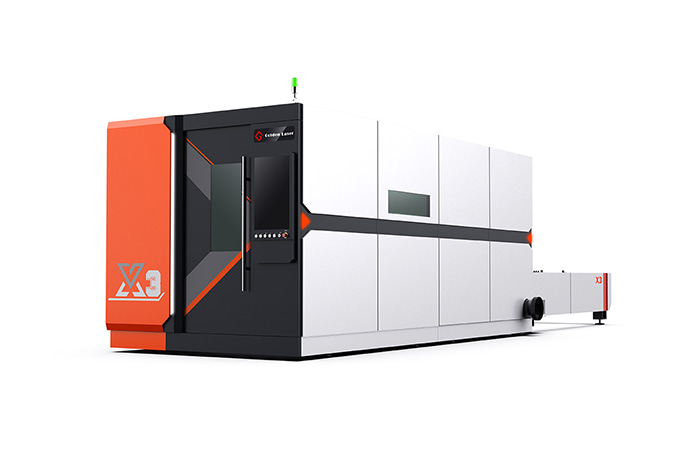

Economic Fiber Laser Sheet Cutting Machine Parameters |

|

| Laser power | 1500W to 6000W |

| Laser source | IPG / Raycus / Max fiber laser generator |

| Laser generator working mode | Continuous/Modulation |

| Beam mode | Multimode |

| Processing surface (L × W) | 1.5m X 3m (Exchange Table) |

| X axle stroke | 3050mm |

| Y axle stroke | 1520mm |

| Z axle stroke | 200mm |

| CNC system | FSCUT controller |

| Power supply | AC380V±5% 50/60Hz (3 phase) |

| Total Power consumption | Depend on the laser source |

| Position accuracy (X, Y and Z axle) | ±0.03mm |

| Repeat position accuracy (X, Y and Z axle) | ±0.02mm |

| Maximum position speed of X and Y axle | 80m/min |

| Max load of working table | 900kg |

| Auxiliary gas system | Dual-pressure gas route of 3 kinds of gas sources |

| Format supported | AI, BMP, PLT, DXF, DST, etc. |

| Floor space | 2.5m x 8.5m |