Factory directly supply Sheet Tube Laser Cutter - Robotic Arm Fiber Laser 3D Cutting Machine – Vtop Fiber Laser

Factory directly supply Sheet Tube Laser Cutter - Robotic Arm Fiber Laser 3D Cutting Machine – Vtop Fiber Laser Detail:

Product detail pictures:

Related Product Guide:

Co-packing and the rise of digital printing | 2000w Laser Cutting Machine

Improving egg carton printing efficiencies | Tube Aluminium Cutting Machine

Persisting in "High high quality, Prompt Delivery, Aggressive Price", we've established long-term cooperation with clients from the two overseas and domestically and get new and old clients' superior comments for Factory directly supply Sheet Tube Laser Cutter - Robotic Arm Fiber Laser 3D Cutting Machine – Vtop Fiber Laser , The product will supply to all over the world, such as: Cologne , Jamaica , Islamabad , Our advantages are our innovation, flexibility and reliability which have been built during last 20 years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!

Factory directly supply Sheet Tube Laser Cutter - Robotic Arm Fiber Laser 3D Cutting Machine – Vtop Fiber Laser Detail:

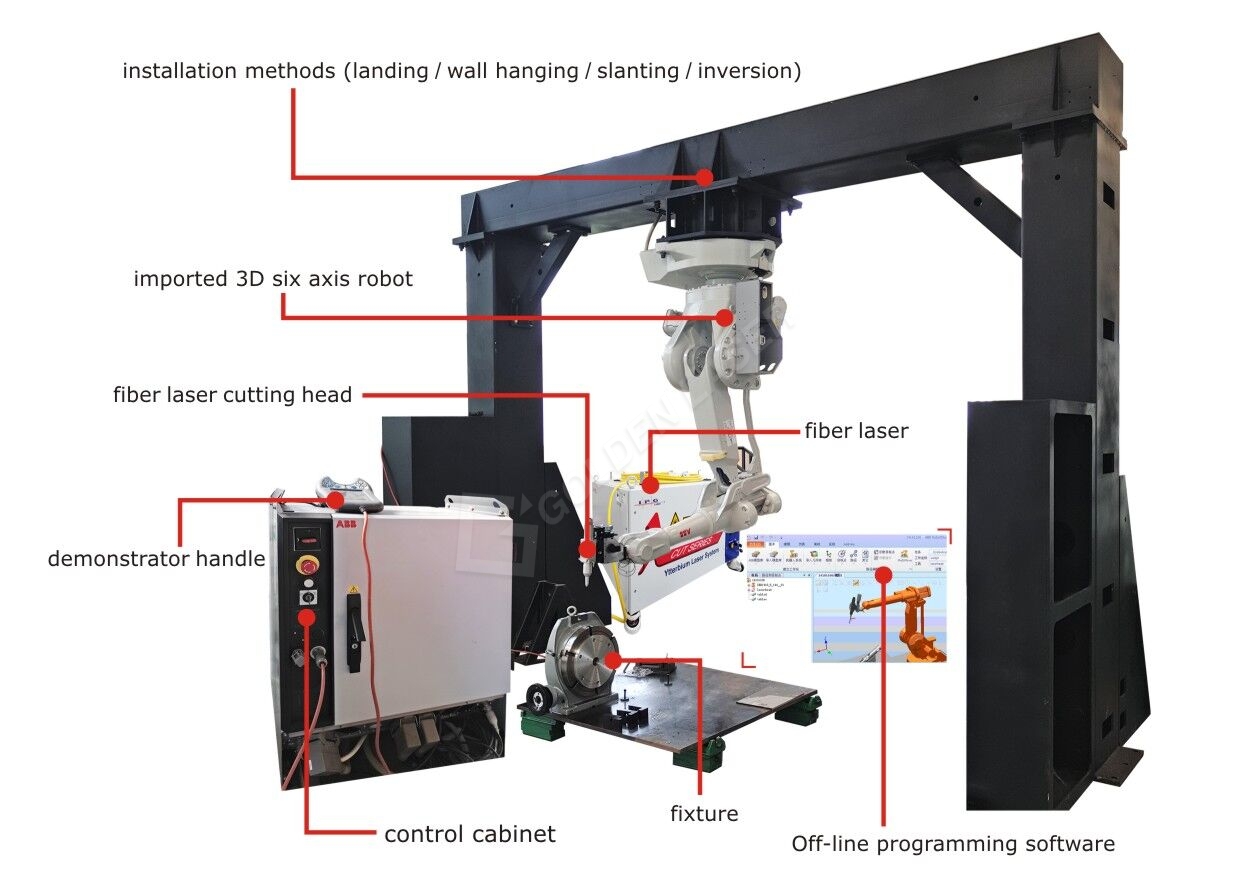

Fiber Laser Robotic Arm 3D Cutting Machine

Machine Highlights

1. XR160L for my company positioning automotive sheet metal processing industry-specific robot, the equipment by the Stäubli RX160L robot, IPG500W fiber laser, LASERMECH laser head (including the moving mechanism), positioning table, chiller, safety and other core components.

2. 6-axis linkage, a wide range of work, up to a long distance, load-bearing capacity, can be in the work space for 3D track cutting

3. Compact, wrist slim, even in harsh conditions, restrictions on a lot of places, can still achieve high-performance operation

4. Process speed and positioning can be adjusted, to achieve the best manufacturing accuracy, high yield

5. Low noise, routine maintenance interval is long, long service life

6. The manipulator can be manipulated through a handheld terminal

7. By modifying the program and hardware changes, can achieve welding, packaging, handling and other functions

Machine Features

1.Laser source: the use of high-performance fiber lasers, high efficiency, low cost of integrated use.

2.The implementation of the cutting of the implementing agencies for the Swiss Staubli robot. Staubli robot is the robot robot industry’s most accurate robot. The use of aluminum titanium alloy robot body, harmonic reducer design, the robot body relative to other brands, light weight, fast, high precision. TL160L robot in the small curvature of the fine cut and large format to tell the cut relative to other brands have obvious advantages. In high-speed cutting, Staubli robots can achieve a speed of 18 m / min without jitter, other brands rarely guarantee the cutting speed of 10 m / min to ensure good cutting results. Also in the small round cut, you can cut the smallest diameter of 2mm small round, cutting effect smooth and beautiful, which other brands of robots can not do.

3.Staubli robot can be configured according to the actual needs of customers off-line programming software, software can read the three-dimensional mapping software everywhere vda, igs, x_t, sldprt, prt, par and other formats, directly in the software compiler track procedures, Teaching, simple and efficient to achieve the product of the type of programming work.

4.Follow the cutting head: optional with the international top brands of the cutting head to ensure that the laser is always in the focus position to ensure the cutting effect.

5.Auxiliary air blowing system: the system integrates high pressure air, nitrogen, oxygen three gas source structure and high and low voltage conversion gas path, the customer can choose according to the processing quality requirements and cost of auxiliary gas.

6.Lubrication system: The machine is equipped with manual lubrication system, reduce the wear of moving parts, to ensure the speed of the whole machine.

Robotic Arm 3D Laser Cutter For Automotive Manufacturing demo Video

Product detail pictures:

Related Product Guide:

Improving egg carton printing efficiencies | Fiber Laser Cutter With Shuttle Table

World Bank’s blockchain bond raises $110 million | 2000w Laser Cutting Machine

To be able to ideal satisfy client's requirements, all of our operations are strictly performed in line with our motto "High High-quality, Competitive Price tag, Fast Service" for Factory directly supply Sheet Tube Laser Cutter - Robotic Arm Fiber Laser 3D Cutting Machine – Vtop Fiber Laser , The product will supply to all over the world, such as: Florence , South Korea , Doha , Ensuring high product quality by choosing the best suppliers, now we have also implemented complete quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.