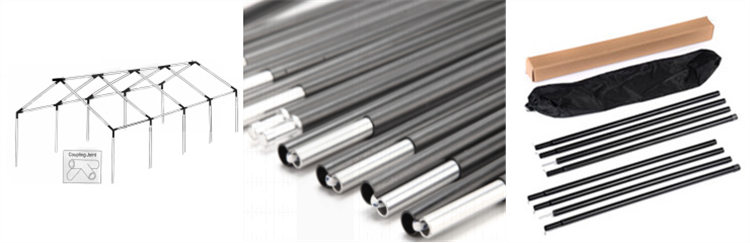

Hoʻohana ʻia nā hale lole stent i nā ʻano kiʻi, aia me ka stent metala, canvas a me ka tarpaulin. He mea maikaʻi kēia ʻano hale lole no ke kani ʻana o ke kani, a me ka rigidity maikaʻi, ka paʻa ikaika, ka mālama ʻana i ka wela, ka wikiwiki a me ka hoʻihoʻi hou ʻana. ʻO nā stents ke kākoʻo o ka hale lole, ua hana maʻamau ia mai ke kila aniani a me ke alumini alumini, ʻo ka lōʻihi o ka stent mai 25cm a 45cm, a ʻo ke anawaena o ke pole kākoʻo he 7mm a 12mm.

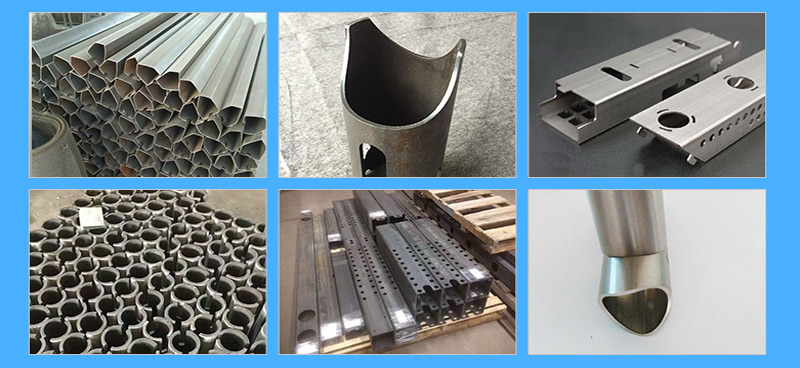

I kēia mau lā, ua loaʻa iā mākou kahi mea kūʻai aku no ka hana hale lole waho, kipa i kā mākou hale hana. Mai ka mea kūʻai mai, ua ʻike mākou he nui nā kaʻina hana stent, e like me ka ʻili paipu, ka hana ʻana o ka lathe, nā hole punch a me ka drill, pipe TIG welding etc.

ʻO ka mea mua, pono ia i ka mīkini ʻili no ka ʻoki ʻia ʻana o ka paipu, pono ke ʻoki ʻia e like me ke kaha kiʻi a pono e wehe i nā burrs koi ma ka manual.

ʻO ka lua, hele pū me ka hana lathe no ka ʻoki ʻana i ka chamfer a me ka wehe ʻana i nā puka o loko a i waho paha.

ʻO ke kolu, ma hope o ka ʻoki ʻana, pono ia i ka mīkini kuʻi a me ka mīkini hoʻoheheʻe ʻana no ka hole punch a me ka drill etc.

ʻO ka hā, pono e wili pū ʻia ka paipu, a pono ka mea kanu e hoʻopili i ka lepili e hōʻailona ai i ka paipu a pau.

Ma hope o kēia mau kaʻina hana, loaʻa ka stent i ka hale hana. Akā, pono ia i nā ʻāpana he nui o ka ʻeli, ka kuʻi, nā mīkini wili, akā pono pū kekahi i nā limahana he nui.

I mea e hoʻomaikaʻi ai i ka pono hana a hoʻololi i nā koi hana hou, ua hana ka mea kūʻai aku i nā noiʻi mākeke, i ka hope ua hoʻopili lākou i ka laser gula a makemake lākou e hoʻolauna i ka mīkini wiliwī GOLDEN-VTOP LASER.

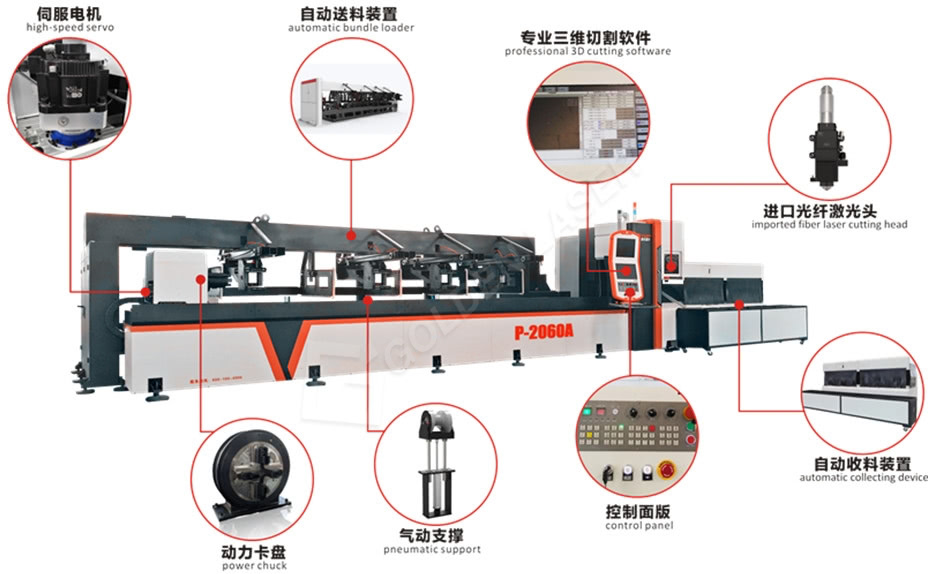

ʻO ka mīkini ʻokiʻoki laser pipe Golden Vtop he kūpono ia no nā ʻano o ka paipu a i ʻole ka ʻoki paipu, hiki iā ia ke hana i ka paipu a i ʻole ka lōʻihi o 6m, 8m a me 12m, a me ke anawaena o 10-300mm. I kēia manawa ua hoʻohana maikaʻi ʻia i nā ʻoihana e like me ka hoʻoheheʻe ʻana i ka paipu, nā lako hoʻoikaika kino, nā lako kila, nā chassis kaʻa, ka hale hōʻikeʻike a me nā papa, ke kūkulu ʻana a me nā mea ʻē aʻe.

A loaʻa iā ia nā pōmaikaʻi penei:

1. E mālama i ka hana a me ka papahele

No ka mea hiki i ka mīkini ʻoki laser paipu ke hōʻemi i nā mīkini punch 3-4, 1-2 mau mīkini wili, 1-2 mau mīkini ʻike abrasive. Pēlā e mālama ai i ka papahele o 1-2 mau papa hana a me nā koina kanaka ma kahi o 7 kanaka. E ho'ēmi i ke kaʻina hana a mālama i ka manawa.

Hiki i ka mīkini ʻoki laser paipu ke hoʻokō i ka māka maʻamau, ʻoki ʻia a CNC i ka manawa hoʻokahi, kūpono ia no nā ʻano paipu a me nā koi ʻokiʻoki (ʻoki ʻia, beveling, slotting, drilling, cutting flowers), a ʻoluʻolu ka ʻoki ʻana me ka ʻole o ka deburring a me ka ʻeleʻele.

2. Mālama i nā mea

Hiki i ka mea ʻoki laser paipu ke helu maʻalahi i ka hoʻolālā a me ke ʻoki ʻana i nā ala, aneane ʻaʻohe mea ʻōpala. ʻAʻohe pilina pololei ma waena o ke poʻo ʻoki a me ka paia paipu, no laila ua maʻalahi ka ʻili o ka ʻoki ʻana a me ka ʻeleʻele ʻole, ʻaʻohe deformation o nā huahana i hoʻopau ʻia a aneane ʻaʻohe poho.

3. Kiekie pololei

Hiki i ka ʻoki ʻoki laser paipu gula ke ʻimi maʻalahi i ka ʻaoʻao a hana i ka hoʻoponopono, ʻoiai me ka ʻoki mau ʻana i ka wā lōʻihi, e hōʻoia mau ana i ka pololei a me ke kūlike o ka huahana i hoʻopau ʻia. Hiki ke hoʻololi a hoʻonohonoho pono ʻia ka chuck, me ka unloading auto, hoʻopau ia i ka hopena artificial i ka huahana i hoʻopau ʻia.