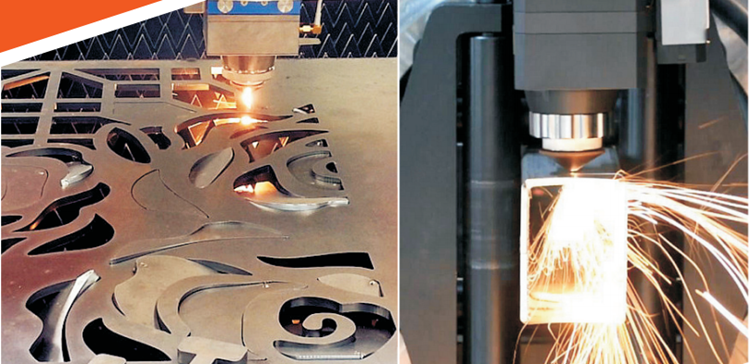

Cov haujlwm laser tam sim no suav nrog kev txiav, vuam, kho cua sov, clapor dependition, engraving, trimming, annealing, thiab kev ua kom tawv nqaij tawv, thiab ua kom tawv nqaij tawv, thiab tawv nqaij tawv. Laser Manufactur cov txheej txheem sib tw ua ke ob leeg ua ke thiab kev lag luam thiab cov tshuab hluav taws xob, thiab hluav taws xob tua hluav taws xob txiav, ntshav txiav thiab nplaim txiav.

Dej dav hlau txiav yog cov txheej txheem siv los txiav cov ntaub ntawv siv lub dav hlau ntawm cov dej khov ua kom siab 60,000 phaus ib square nti (psi). Feem ntau, cov dej sib xyaw nrog cov abrasive zoo li garnet uas ua rau cov ntaub ntawv ntxiv kom raug kaw kom zoo, squarely thiab nrog lub zoo ntug tiav. Cov dav hlau dej muaj peev xwm txiav ntau cov ntaub ntawv muaj xws li stainless hlau, titanium, cuab yeej hlau, granite, thiab armor phaj. Tus txheej txheem no tsim lub suab tseem ceeb.

Cov lus uas ua raws muaj kev sib piv ntawm cov hlau txiav kev txiav cov co2 laser txiav thiab dej txiav cov txheej txheem hauv kev lag luam khoom.

§ Cov txheej txheem tseem ceeb sib txawv

§ Cov ntaub ntawv thov raug thiab siv

§ Thawj zaug ua lag luam thiab cov nqi ua haujlwm nruab nrab

§ Precision ntawm cov txheej txheem

§ Xav txog kev saib xyuas kev nyab xeeb thiab kev ua haujlwm

Cov txheej txheem sib txawv

| Yam kawm | CO2 Laser | Dej Dav Hlau Txiav |

| Txoj kev ntawm cov khoom siv hluav taws xob | Lub teeb 10.6 m (deb infrared ntau) | Ywg dej |

| Tau qhov twg los ntawm lub zog | Roj laser | Kev Kub Siab Twj |

| Lub zog yuav kis tau li cas | Nqaj coj los ntawm tsom iav (ya optics); Fiber ntau-kis tsis tau ua tau rau co2 laser | Rigid Kev Kub Siab Hoves Tau Txais Lub Zog |

| Yuav ua li cas cov khoom siv raug ntiab tawm | Roj dav hlau, ntxiv rau cov roj ntxiv roj ntxiv | Cov Khoom Siv Dej Siab Tshaj Tawm Cov Khoom Siv Pov Tseg |

| Nyob deb ntawm nozzle thiab khoom siv thiab siab tshaj plaws tso siab thev | Kwv yees li 0.2 "0.004", nrug deb, kev cai thiab Z-axis tsim nyog | Kwv yees li 0.12 "0.04", kev nrug deb, kev cai thiab z-axis tsim nyog |

| Lub cev siv lub tshuab siv-up | Laser Tau Nyob Sab Hauv Tshuab | Lub chaw ua haujlwm thiab cov twj tso kua mis tuaj yeem nyob sib cais |

| Ntau ntawm cov rooj ntau thiab tsawg | 8 'X 4' txog 20 'x 6.5' | 8 'x 4' txog 13 'x 6.5' |

| Raug nqaj tso zis ntawm lub workpiece | 1500 rau 2600 watts | 4 txog 17 kilowatts (4000 bar) |

Cov txheej txheem raug thiab siv

| Yam kawm | CO2 Laser | Dej Dav Hlau Txiav |

| Cov txheej txheem kev siv | Txiav, drilling, engraving, ablation, qauv, vuam | Txiav, ablation, qauv |

| 3D Khoom Txiav | Nyuaj vim yog bigid nqaj kev taw qhia thiab cov kev cai ntawm qhov deb | Ib feem tau ua tau txij li lub zog uas seem tom qab lub workpiece raug rhuav tshem |

| Cov ntaub ntawv tuaj yeem txiav los ntawm cov txheej txheem | Txhua cov hlau (tsis suav nrog cov hlau ua ke), txhua yam plastics, iav, thiab ntoo tuaj yeem txiav | Txhua cov ntaub ntawv tuaj yeem txiav los ntawm cov txheej txheem no |

| Cov Khoom Siv Ua Ke | Cov ntaub ntawv nrog cov ntsiab lus melting sib txawv tuaj yeem txiav | Ua tau, tab sis muaj kev phom sij ntawm delamination |

| Sandwich qauv nrog kab noj hniav | Qhov no ua tsis tau nrog ib co2 laser | Tsawg lub peev xwm |

| Txiav cov ntaub ntawv nrog kev txwv lossis tsis txaus ntseeg | Tsis tshua muaj kev ua tau vim muaj kev deb me me thiab lub laser txiav loj | Txwv vim muaj qhov deb me me ntawm lub nozzle thiab cov khoom siv |

| Cov khoom ntawm cov khoom txiav uas cuam tshuam ua | Kev nqus cov yam ntxwv ntawm cov khoom ntawm 10.6m | Khoom Siv Hardness yog qhov tseem ceeb |

| Cov khoom siv tuab ntawm qhov kev txiav lossis kev ua lag luam yog nyiaj txiag | ~ 0.12 "rau 0.4" nyob ntawm cov khoom | ~ 0.4 "rau 2.0" |

| Cov kev siv rau cov txheej txheem no | Kev txiav cov ntawv hlau hlau ntawm daim ntawv txheej hauv nruab nrab rau sheet ua | Txiav ntawm pob zeb, ceramics, thiab cov hlau ntawm ntau dua thickness |

Thawj zaug kev nqis peev thiab nruab nrab kev ua haujlwm

| Yam kawm | CO2 Laser | Dej Dav Hlau Txiav |

| Kev pib peev yuav tsum tau ua | $ 300,000 nrog 20 KW twj tso kua mis, thiab muaj 6,5 x 4 'lub rooj | $ 300,000 + |

| Seem uas yuav hnav tawm | Tiv tes iav, roj Nozzles, ntxiv rau ob qho tib si hmoov av thiab cov ntxaij lim dej | Cov dej dav hlau nozzle, tsom iav ua kom sov, thiab txhua yam kev kub siab xws li li qub, hoses, thiab ntsaws ruaj ruaj |

| Qhov nruab nrab hluav taws xob tau noj lub zog txiav tiav | Xav tias muaj 1500 watt co2laser: Siv hluav taws xob: 24-40 kw Laser roj (CO2, N2, nws): 2-16 L / H Tej roj (O2, N2): 500-2000 L / H | Xav tias muaj 20 kw twj tso kua mis: Siv hluav taws xob: 22-35 kw Dej: 10 l / h Abrasive: 36 kg / h Pov tseg ntawm kev txiav pov tseg |

Precision Ntawm Cov Txheej Txheem

| Yam kawm | CO2 Laser | Dej Dav Hlau Txiav |

| Qhov tsawg kawg nkaus ntawm qhov txiav txiav | 0.006 ", nyob ntawm kev txiav ceev | 0.02 " |

| Txiav cov npoo npoo | Txiav saum npoo yuav qhia cov qauv txheej txheem striated | Kev txiav nto yuav tshwm sim tau cov xuab zeb-blasted, nyob ntawm qhov kev txiav ceev |

| Qib ntawm kev txiav cov npoo mus rau thaum kawg | Zoo; Qee zaum yuav ua rau muaj npoo | Zoo; Muaj ib qho "tw" cov nyhuv rau hauv nkhaus nyob rau hauv cov ntaub ntawv ntawm cov ntaub ntawv tuab |

| Ua hwm | Kwv yees li 0.002 " | Kwv yees li 0.008 " |

| Qib ntawm crush ntawm kev txiav | Tsuas yog ib nrab crusher tshwm sim | Tsis muaj crush tshwm sim |

| Thermal Kev Nyuaj Siab Ntawm Cov Khoom | Deformation, tempering thiab cov kev hloov pauv yuav tshwm sim hauv cov khoom | Tsis muaj kev ntxhov siab thermal |

| Cov tub rog ua yeeb yam ntawm cov khoom siv hauv kev taw qhia roj lossis dej nyab thaum ua | Roj Siab Zoo teeb meem nrog nyias workpieces, deb tsis tuaj yeem tswj hwm | High: Nyias, ntu me me tuaj yeem yog tsuas yog ua tiav rau kev txwv tsawg |

Kev txiav txim siab kev nyab xeeb thiab kev khiav haujlwm ib puag ncig

| Yam kawm | CO2 Laser | Dej Dav Hlau Txiav |

| Kev Nyab Xeeb Tus KheejCov cuab yeej xav tau | Laser kev tiv thaiv kev nyab xeeb tsom iav tsis yog qhov tsim nyog kiag li | Kev tiv thaiv kev nyab xeeb kev tiv thaiv kev nyab xeeb, kev tiv thaiv pob ntseg, thiab tiv thaiv tiv thaiv kev sib cuag nrog cov dej kub siab yog xav tau |

| Kev tsim cov pa luam yeeb thiab hmoov av thaum ua | Puas muaj tshwm sim; Cov Plastics thiab qee cov hlau ib txwm yuav tsim cov roj lom lom | Tsis muaj feem xyuam rau cov dej dav hlau txiav |

| Suab nrov thiab txaus ntshai | Tsawg heev | Tsis muaj siab |

| Tshuab Kev Tu Yuav Tsum Tau Ua Raws Li Cov Qauv Mess | Tsawg huv | Siab huv si |

| Txiav cov pov tseg ua los ntawm cov txheej txheem | Kev txiav khib nyiab yog tsuas yog nyob rau hauv daim ntawv ntawm hmoov av uas xav tau nqus tawm thiab lim | Cov khoom muaj ntau ntawm cov khib nyiab tshwm sim vim yog cov dej sib xyaw nrog cov abrasives |