The fiber laser cutting machine adopts advanced technology and unique design to ensure machine stable operation and maintain constant power. The cutting gap is uniform, and the calibration and maintenance are convenient. The closed light path guides the lens to ensure the cleanliness and service life of the lens. The closed optical light guide ensure the cleanliness and service life of the lens. It is a high-tech equipment integrating the most advanced fiber laser technology, numerical control technology and precision mechanical technology. GF-JH Series – 6000W fiber laser cutting ability (metal cutting thickness)

GF-JH Series – 6000W fiber laser cutting ability (metal cutting thickness)

|

Material |

Cutting Limit |

Clean Cut |

|

Carbon steel |

25mm |

22mm |

|

Stainless steel |

20mm |

16mm |

|

Aluminum |

16mm |

12mm |

|

Brass |

14mm |

12mm |

|

Copper |

10mm |

8mm |

|

Galvanized steel |

14mm |

12mm |

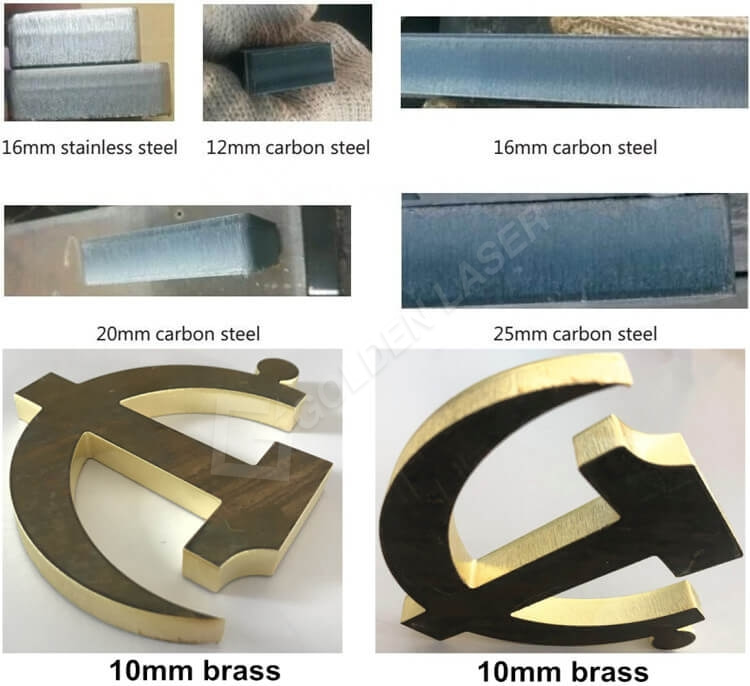

6000W Fiber Laser Cutting Sheets Samples Demonstration

Advantages of GF-JH Series – 6000W fiber laser cutting machine:

Beam quality: smaller focusing spot, finer cutting lines, higher work efficiency and better processing quality;

Cutting speed: twice the speed of same power laser cutting machine;

Usage cost: The total power consumption is about 30% of the traditional CO2 laser cutting machine;

Maintenance cost: fiber transmission, no need to use reflective lenses which saves a lot of maintenance costs;

Easy operation and maintenance: optical fiber transmission, no need to adjust the optical path;

Flexible light guiding effect: small size, compact structure and suitable for flexible process;

Large working format: the working area is range from 2000*4000mm to 2500*8000mm;

Watch the Video – 6000w Fiber Laser Cutting 10mm Brass Sheet with High Speed

and High Precision

Features of fiber laser cutting machine:

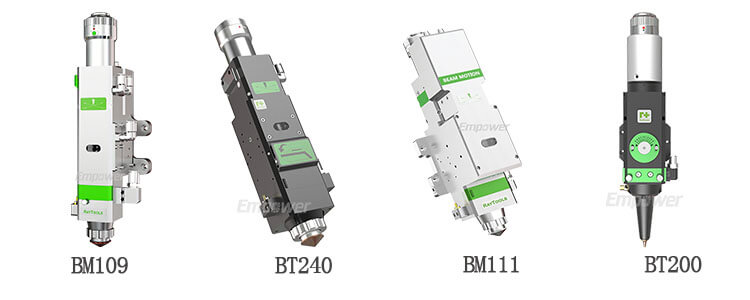

1. Adopting advanced Swiss Raytools fiber laser cutting head, the focusing is fast and accurate, the drawer protection lens is easy to replace, and the anti-collision design can effectively avoid laser head loss caused by the unevenness of the plate.

2. The long shaft adopts double drive rack and pinion transmission (Taiwan YYC gear rack). The rack and pinion drive improves the high-speed cutting capability and can ensure cutting accuracy at high cutting speed (120m/min). The double-drive transmission has better balance, which makes the equipment run more smoothly and with higher precision.

2. The long shaft adopts double drive rack and pinion transmission (Taiwan YYC gear rack). The rack and pinion drive improves the high-speed cutting capability and can ensure cutting accuracy at high cutting speed (120m/min). The double-drive transmission has better balance, which makes the equipment run more smoothly and with higher precision. 3. The rack and pinion lubrication is controlled by micro-computer automatic lubrication, no need manual control, so it ensures the rack and pinion be fully lubricated at any time.

3. The rack and pinion lubrication is controlled by micro-computer automatic lubrication, no need manual control, so it ensures the rack and pinion be fully lubricated at any time.

4. The machine adopts gantry beam structure, fully guarantee the machine high-speed running and cutting accuracy at high speed.

Applicable materials:

It can cut a variety of metal sheets and pipes, and is mainly suitable for rapid cutting of stainless steel, carbon steel, galvanized sheet, various alloy sheets, rare metals and other materials.

Applied industry:

Suitable for aerospace technology, aircraft manufacturing, rocket manufacturing, robot manufacturing, elevator manufacturing, shipbuilding, sheet metal cutting, kitchen furniture, automotive parts, heat and ventilation ducts, chassis cabinets, kitchen cabinets, machinery manufacturing, etc.