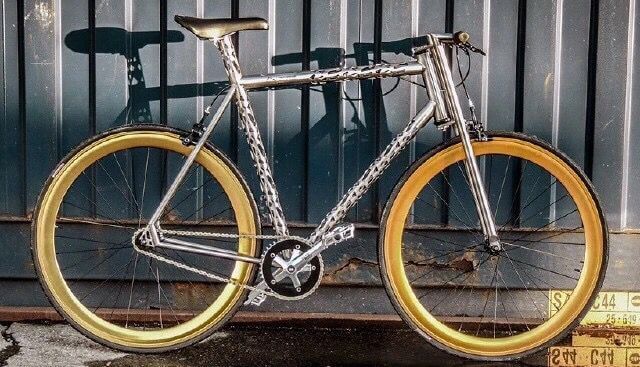

Nowadays, green environmental are advocated, and many people will choose to travel by bicycle. However, the bicycles you see when you walk on the streets are basically the same. Have you ever thought about owning a bicycle with your own personality? In this high-tech era, laser tube cutting machines can help you achieve this dream.

In Belgium, a bicycle called “Erembald” has attracted a lot of attention, and the bicycle is limited to only 50 cars worldwide.

This bicycle is made with a laser tube cutting machine that meets the requirements of different cycling enthusiasts to achieve the desired effect. The “Erembald” bike is made entirely of stainless steel and has a simple shape. Then, to create such a cool bike, you must have one set tube laser cutting machine.

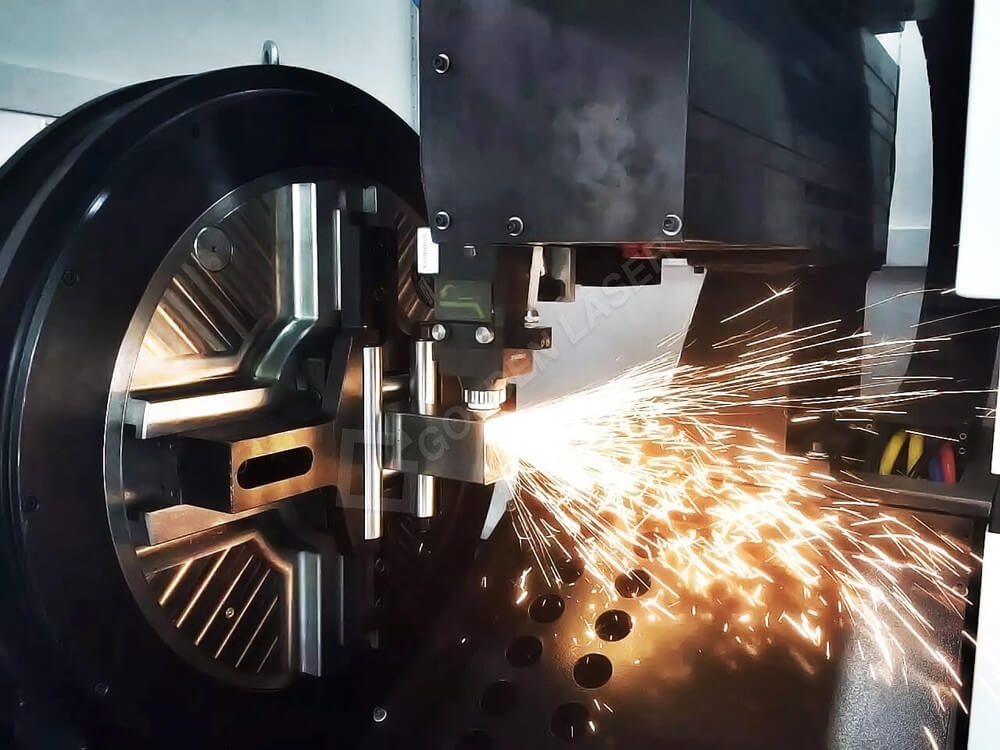

Laser tube cutting machine is a special machine tool that uses laser technology to carry out various graphic cutting on pipe fittings and profiles. It is a high-tech product integrating numerical control technology, laser cutting and precision machinery. With professional, high speed, high precision, high efficiency, high cost performance, it is the first choice for the non-contact metal pipe processing industry.

At present, the bicycle skeleton is made of pipe material, and the pipe material has the following two advantages:

First, the weight is relatively light, and second, the pipe has a certain strength. Most of the pipe materials used in bicycles are aluminum alloy, titanium alloy, chrome molybdenum steel, carbon fiber, lifting pipe and structural design ability and innovative processing technology, which has become the eternal melody of the bicycle industry innovation and development.

Laser cutting tube materials is a cutting process which has become more popular in recent years. Compared with the traditional cutting process, the laser cutting tube materials has a smoother cutting section, and the cut tube productscan be directly used for welding, reducing the processing process in the bicycle industry. Compared to traditional pipe processing, which requires cutting, blanking, and bending, the traditional pipe processing process consumes a large number of molds. The laser cutting tube not only has fewer processes, but also has higher efficiency and better quality of the cut workpiece. At present, the world’s bicycle industry has a large market development space with the rapid growth of the national fitness tide.

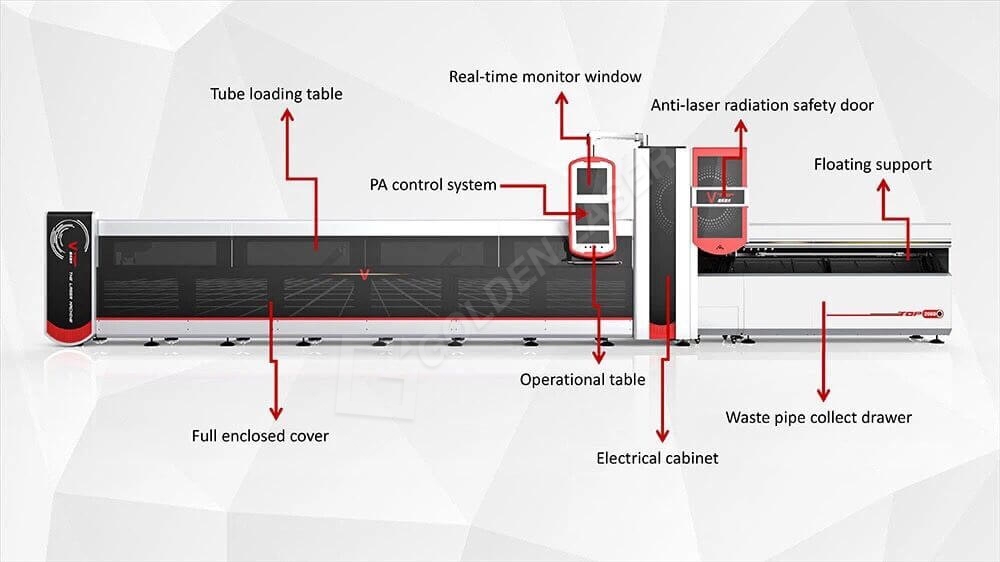

Advantages of Golden Laser Tube Cutting Machine P2060A

1. High precision

The tube laser cutting machine adopts the same set of fixture system, and the programming software completes the processing design, and completes the multi-step processing at one time, with high precision, smooth cutting section and no burr.

2. High efficiency

The tube laser cutting machine can cut several meters of tubing in one minute, a hundred times more than the traditional manual method, which means that laser processing is highly efficient.

3. Flexibility

Tube laser cutting machines can be flexibly machined in a variety of shapes, which allows designers to perform complex designs that are unthinkable under traditional processing methods.

4. Batches processing

The standard pipe length is 6 meters. The traditional processing method requires very bulky clamping, while the pipe laser cutting machine can easily complete several meters of pipe clamping positioning. The laser pipe cutting machine can complete the automatic material filling of the pipe in batches. , automatic correction, automatic detection, automatic feeding, automatic cutting, effectively reducing labor costs.

It is precisely because of the unique flexible processing method of the laser cutting machine that the bicycle frame can also be used to create other styles. The unique manufacturing process makes the whole bicycle glow with different brilliance, which is the best way to produce and process small batch bicycles.

P2060A Machine Technical Parameters

| Model number | P2060A / P3080A | ||

| Laser power | 1000w / 1500w / 2000w / 2500w / 3000w / 4000w | ||

| Laser source | IPG / nLight fiber laser resonator | ||

| Tube length | 6000mm, 8000mm | ||

| Tube diameter | 20mm-200mm / 20mm-300mm | ||

| Tube type | Round, square, rectangular, oval, OB-type, C-type, D-type,triangle, etc (standard); Angle steel, channel steel, H-shape steel, L-shape steel, etc (option) |

||

| Repeat position accuracy | ± 0.03mm | ||

| Position accuracy | ± 0.05mm | ||

| Position speed | Max 90m/min | ||

| Chuck rotate speed | Max 105r/min | ||

| Acceleration | 1.2g | ||

| Graphic format | Solidworks, Pro/e, UG, IGS | ||

| Bundle size | 800mm*800mm*6000mm | ||

| Bundle weight | Max 2500kg | ||

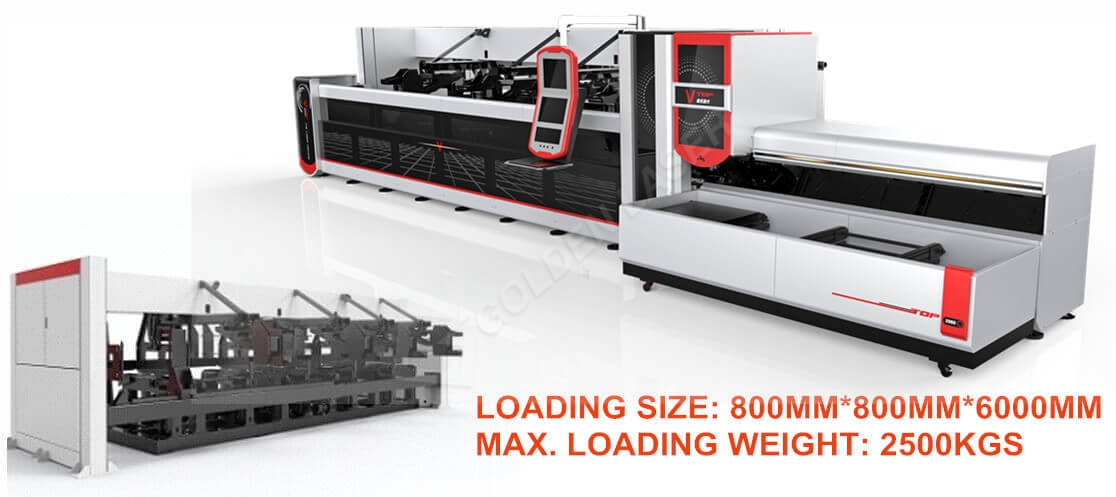

| Other Related Professional Pipe Laser Cutting Machine With Automatic Bundle Loader | |||

| Model number | P3060 | P3080 | P30120 |

| Pipe processing length | 6m | 8m | 12m |

| Pipe processing diameter | Φ20mm-200mm | Φ20mm-300mm | Φ20mm-300mm |

| Applicable types of pipes | Round, square, rectangular, oval, OB-type, C-type, D-type,triangle, etc (standard); Angle steel, channel steel, H-shape steel, L-shape steel, etc (option) |

||

| Laser source | IPG/N-light fiber laser resonator | ||

| Laser power | 700W/1000W/1200W/2000W/2500W/3000W/4000W | ||

Watch The Video Of Laser Pipe Cutting Machine P2060A