Application of Stainless Steel Laser Cutting Machine in Decoration Engineering Industry

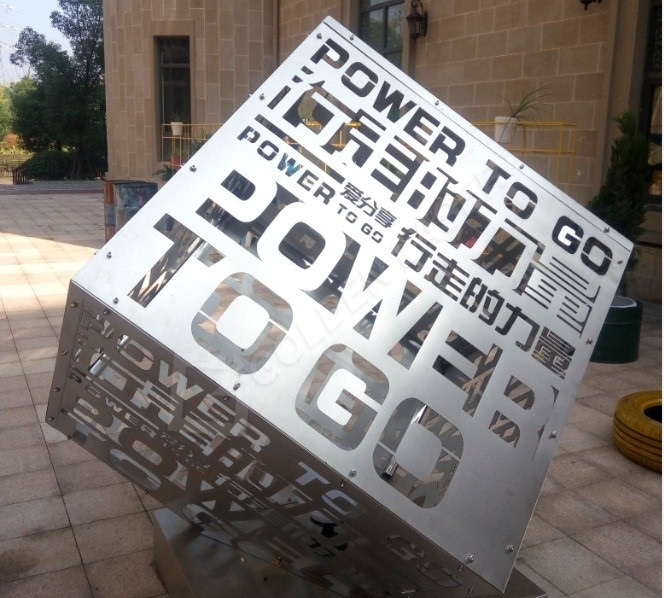

Stainless steel is widely used in the decorative engineering industry due to its strong corrosion resistance, high mechanical properties, long-term surface colorfastness, and varying shades of light depending on the angle of light. For example, in the decoration of various top-level clubs, public leisure places, and other local buildings, it is used as a material for curtains, hall walls, elevator decorations, sign ads, and front desk screens.

However, if stainless steel plates are to be made into stainless steel products, it is a very complicated technical task. Many processes are required in the production process, such as cutting, folding, bending, welding, and other mechanical processing. Among them, the cutting process is an important process. There are many kinds of traditional processing methods for stainless steel cutting, but the efficiency is low, the molding quality is poor and it rarely meets the requirements of mass production.

At present, stainless steel laser cutting machines are widely used in the metal processing industry due to their good beam quality, high precision, small slits, smooth cut surfaces, and the ability to flexibly cut arbitrary graphics. The decorative engineering industry is no exception. Look at the application of stainless steel laser cutting machine in the decoration industry.