PriceList for 2000w Fiber Laser Cutter Price - ABB Fiber Laser Robot Arm 3D Cutting Tube / Pipe For Auto Parts – Vtop Fiber Laser

PriceList for 2000w Fiber Laser Cutter Price - ABB Fiber Laser Robot Arm 3D Cutting Tube / Pipe For Auto Parts – Vtop Fiber Laser Detail:

Product detail pictures:

Related Product Guide:

Stolen metals fuel N.J. opioid crisis, state report says | News | Ms Plate Cutting Machine For Metal Furniture

Imaging Magnetism With A Hall Effect Camera | Tube Aluminium Cutting Machine

"Sincerity, Innovation, Rigorousness, and Efficiency" will be the persistent conception of our company to the long-term to establish together with customers for mutual reciprocity and mutual gain for PriceList for 2000w Fiber Laser Cutter Price - ABB Fiber Laser Robot Arm 3D Cutting Tube / Pipe For Auto Parts – Vtop Fiber Laser , The product will supply to all over the world, such as: Hyderabad , Liverpool , Hamburg , Our company will adhere to "Quality first, , perfection forever, people-oriented , technology innovation"business philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant skilled knowledge, to develop advanced production equipment and production process , to create the first-call quality solutions, reasonable price , high quality of service , quick delivery , to offer you create new value .

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.

PriceList for 2000w Fiber Laser Cutter Price - ABB Fiber Laser Robot Arm 3D Cutting Tube / Pipe For Auto Parts – Vtop Fiber Laser Detail:

ABB Fiber Laser Robot Arm 3D Cutting Tube / Pipe

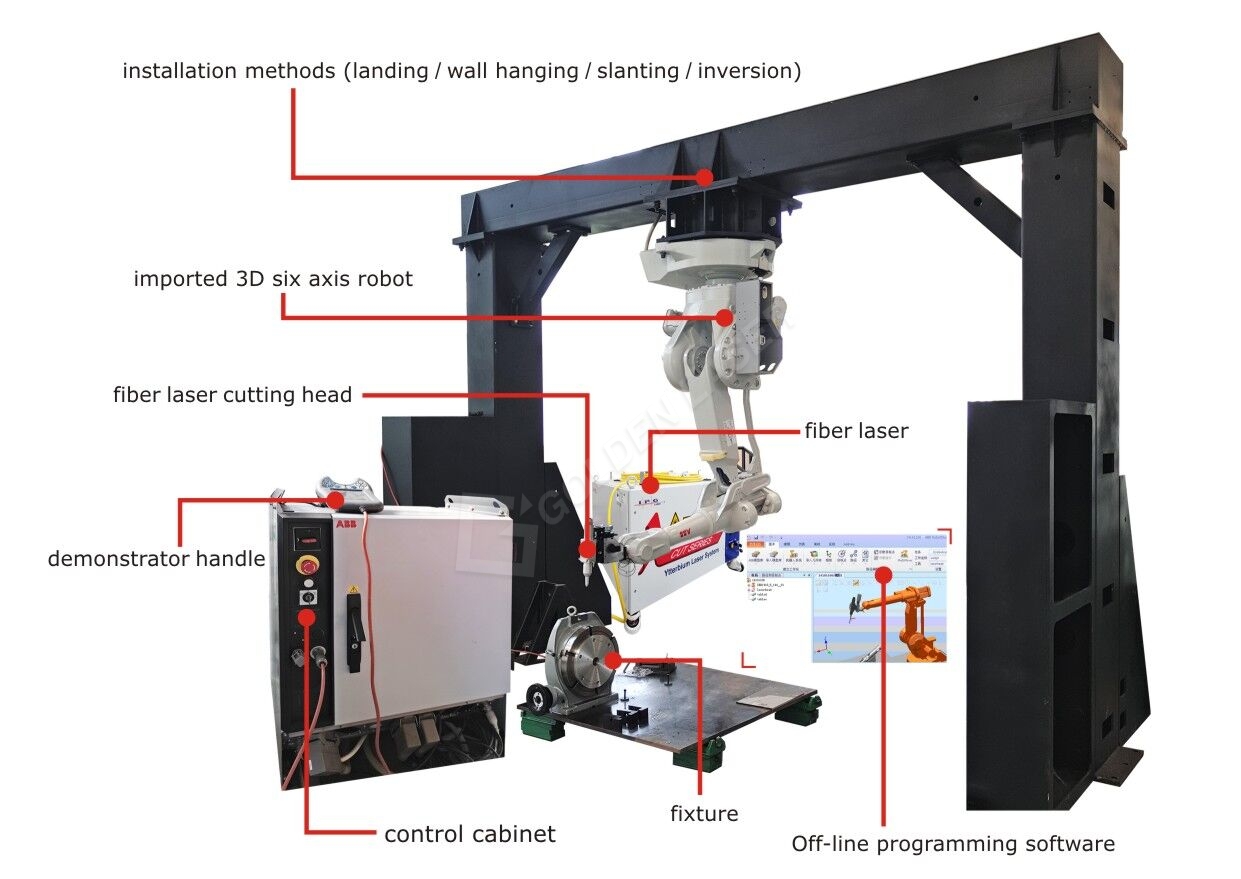

X2400D / L is a special robot for the company’s auto parts processing industry and this equipment consists of ABB2400L robot, IPG1000W fiber laser, LASERMECH laser head (including follower mechanism), positioning table, and water chiller.

Machine Advantages

1. It perfectly integrated with the world famous ABB robot arm and fiber cutting technology which represents the most advanced level of laser cutting, and it can realize automated production in maximum degree.

2. 6-axis linkage makes the working area larger and reach long stretch distance with long loading ability, and it can perform 3D track cutting within the working space.

3. Due to the compact structure and slim robot wrist, it can realize high performance operation even if with limited floor space.

4. The process speed and position can be adjusted to achieve the best manufacturing precision and good production rate.

5. Low noise and long routine maintenance intervals, so the machine service time is longer.

6. The robot arm can be controlled by the manual handle.

7. By changing the program and machine hardware, the robot arm can achieve the function of laser cutting or laser welding

Robotic Arm 3D Laser Cutting Machine For Auto Parts Industry In Korea

Customer Site – ABB 3D Robotic Arm Fiber Laser Cutting Machine For Automotive Industry In China

Product detail pictures:

Related Product Guide:

Police release images of Toyah Cordingley and her car hours before the 24-year-old was murdered | Fiber Laser Cutter With Shuttle Table

Tecnoglass and Schüco Announce a New Strategic Alliance | Tube Aluminium Cutting Machine

As for competitive charges, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we have been the lowest around for PriceList for 2000w Fiber Laser Cutter Price - ABB Fiber Laser Robot Arm 3D Cutting Tube / Pipe For Auto Parts – Vtop Fiber Laser , The product will supply to all over the world, such as: Moldova , Irish , Bangalore , Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Please your inquiry for more details or request for dealership in selected regions.