Sheet Metal Laser Cutting Machine Series

C Series

“C” series is a compact and small size laser cutting machine

save space, ensures safety protection, intelligent control, and convenient use.

Model No.: C30

Working Area: 3000*1000mm

Fully Closed Single Table Fiber Laser Cutting Machine

Model No.: C20

Working Area: 2000*1000mm

Compact Middle Size Fiber Laser Cutting Machine

Model No.: C15

Working Area: 1500*1000mm

Compact Design Closed Fiber Laser Cutting Machine

Model No.: C06/C08/C10/C12

Working Area: 600*600mm

Small Size Liner Motor Fiber Laser Cutting Machine

E Series

"E" series is an EcoPormance metal sheet laser cutting machine

economical, practical, efficient cutting and cost-effective single-table

Model No.: E3plus / E4plus / E6plus

Advanced Single Table Sheet Metal Laser Cutting Machine

X Series

"X" series is the eXchange table fiber laser cutting machine

automated loading and unloading, higher safety protection and efficient processing capabilities based on economical and high performance.

Model No.: X3

Working Area 3000*1500mm

Exchange Table Sheet Metal Laser Cutting Machine

Model No.: X3t

Working Area 3000*1500mm

Exchange Table Sheet Metal and Tube Laser Cutter

Model No.: X3plus

Working Area 3000*1500mm

Classic exchange Table Fiber Laser Cutting Machine

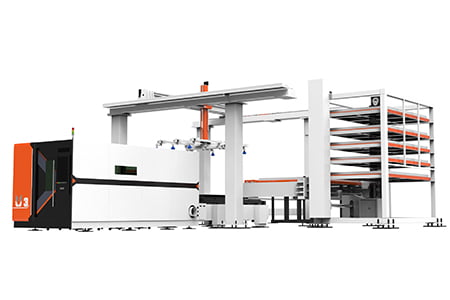

U Series

Ultra series is an industrial 4.0-level laser cutting equipment

that integrates unmanned automatic loading system

automatic nozzle replacement and cleaning, and intelligent control systems that can match the material warehouse.

Model No.: U3

Working Area 3000*1500mm

Automatic Sheet Metal Laser Cutting Machine with towel loader

M Series

Master “M” series is a large format and high-power laser cutting machine

Dual-work platform with High speed metal cutting machine for efficient metalworking processing.

H Series

The Huge "H" series is a large-scale laser cutting machine

that can be modularly customized based on large-format high-power cutting needs.

Golden Laser is one of the best industrial Sheet Metal laser cutting machine manufacturers and suppliers in China since 2005.

As a China-leading sheet metal laser cutting machine factory with over 20 years of laser sheet metal cutting machine production experience. We offer a wide range of CNC laser cutting machines for various metal-plate materials, such as cast steel, stainless steel, forged steel, etc. with high-quality cutting demand. Customized sheet metal fiber laser cutting machine service is also valid with our strong R&D ability. Welcome to contact us for more information and price according to your sheet metal cutting demand.

REQUEST A FREE LASER SHEET METAL MACHINE QUOTE FOR MORE DETAILS

All You Need To Know About Sheet Metal Laser Cutting Machine

Sheet metal laser cutting machine is one a fiber laser cutting machine that only focuses on cutting different sheet metal in different thicknesses and sizes

- Different Power of fiber laser sources can cut the different thicknesses of stainless steel, carbon steel, brass, Aluminum, and so on.

- Sheet metal area related to the sheet metal laser cutting machine cutting area.

- Single or Dural working table optional according to the production quantity.

What is the Advantage of Sheet Laser Cutting Machines?

1. Clean Cutting Edge

Compare with sawing and plasma metal cutting machines, laser cutting result on metal materials is smooth and clean.

2. High-Speed

For up to 3mm sheet metal, laser cutting speed on the metal sheet will be faster than other kinds of metal punching and cutting tools. Especially on the small cutting design.

3. No pressure on the metal surface

Laser cutting is a high-temperature no-touch cutting method, it won't press the materials, and no distortion in the production.

4. Recognize and Save sheet metal materials.

Recognize and check the space is enough to cut the rest of the metal spare parts.

Sheet Metal Laser Cutting Machine Manufacturing Main Parts

How to Work of Sheet Metal Laser Cutting Machines?

The mechanism of the sheet metal laser cutting machine is primarily like this.

1. Loading the right tube onto the laser tube cutting machine (Manual or Automatic loading by choice)

2. Input the right cutting design into the laser cutting machine software,

3. Set the right cutting design parameter according to the metal thickness and type of steel, mild steel, stainless steel, Al, Brass, etc.

4. Check the laser beam.

5. Start Laser Cutting Machine and collect the finished metal parts.

Why Choose Sheet Metal Laser Cutting Machine?

Sheet Metal Laser Cutting Samples

Considerations When Buying Sheet Metal Laser Cutting Machine

It is important to choose the right laser power because the different laser power the price will very different. Choose according to the max thickness, the investment will easily go over your budget. Golden Laser support 1.5kw, 2kw, 3kw, 4kw, 6kw, 8kw, 12kw, 15kw, 30kw fiber laser and so on.

A large area of metal sheet needs a large sheet metal area laser cutting machine it will affect the cost of the metal laser cutting machine price. Golden Laser affords, a 1.5*3meter, 2*4meter, 2*6meter, 2.5*8meter area sheet metal laser cutting machine

Consider your factory situation and choosing a suitable laser controller will be a good choice. If no need connects ERP systems with other milling machines, China controller FSCUT will be a good choice, friendly interface easy to operate.

A useful laser cutting machine is designed according to detailed customer demand, many functions are customized after deeply studying in customer's production find. Which meet the potential demand and simplify and increase the efficiency of the production line. Strong R&D ability is important when you find steel laser cutting machine manufacturers.

As the laser source price reduces a lot, there are more and more metal machinery factories sale the steel laser cutting machine. But in order to supply a good quality steel laser cutting machine, need good experience on light route, electric route, and water route. It does not just compose them together. Golden Laser has 16 years of experience in producing good quality and steady steel laser cutting machines, on-time after service team to ensure the good user experience of the steel laser cutting machine.

Golden Laser exports the laser cutting machine to over 100 different countries and cities, you can check the quality of our machine locally and enjoy door to door on time after service through our agent or factory directly.

Sheet Metal Laser Cutting Machine Option Function

Recognize Function on sheet metal laser cutting machine

Industry camera will be installed beside the laser head to search the metal edge and count the left area of the metal sheet for small spare parts nesting during the production. Save your metal materials mostly.