Ikozvino inorwadza nzvimbo muindasitiri yekugadzira fenicha yesimbi

1. Maitiro acho akaoma: fenicha yechinyakare inotora nzira yekugadzira maindasitiri yekunhonga-saw yekucheka mubhedha-kushandura muchina kugadzirisa-slanting surface-kuboora chinzvimbo proofing uye punching-drilling-kuchenesa-transfer welding inoda 9 process.

2. Zvakaoma kugadzirisa chubhu duku: zvinyorwa zvezvigadzirwa zvekugadzira fenicha hazvina chokwadi. Mudiki ndiye10mm*10mm*6000mm, uye kukora kwemadziro kwepombi kunowanzo0.5-1.5mm. Dambudziko guru mukugadziriswa kwepombi diki nderekuti pombi pachayo ine yakaderera rigidity uye iri nyore kuremara nekunze kwesimba, senge pombi kupeta, kumonyoroka, uye kuputika mushure meextrusion. Maitiro echinyakare ekugadzirisa, akadai sekucheka muchina wekucheka, sawing muchina wekugadzira chikamu uye beveling, punch punching, kudhirowa muchina wekuchera, nezvimwewo, inzira dzekugadzirisa kubata dzinomanikidza chimiro chepombi kuti chikanganiswe nekunze kwesimba extrusion, pamwe nemaitiro mazhinji uye nevanhu vazhinji Kuyerera kwepombi, simba rekudzivirira repombi rinenge kwete, kazhinji kusvika padanho rekupedzisira rechigadzirwa chepombi kana chapedzwa. kugadzirisa, iyo inotora nguva uye yakaoma.

3. Kusarurama kwekugadzira machina: Pasi pechinyakare nzira yekugadzira simbi fenicha pombi, iyo yakazara chaiyo pombi haigone kuvimbiswa. Kungave kuri kugadzira semuchina wekucheka, muchina wekubaya kana muchina wekuchera, pane zvikanganiso zvemachining, kunyanya zvekugadzira michina ine yakaderera dhigirii ye automation control. Kunyanya kutevedzana kwemaitiro, ndiko kuwedzera kwekukanganisa kwemuchina kuunganidza. Zvose zviri pamusoro apa nzira dzekugadzirisa dzinoda kupindira kwevanhu mukugadzirisa kwekugadzirisa, uye kukanganisa kwevanhu kuchawedzerwa kune yekupedzisira kukanganisa kukanganisa kwechigadzirwa. Naizvozvo, iko kurongeka kwechinyakare yakawanda-maitiro ekugadzirisa nzira haidzoreki uye inovimbiswa. Muchikamu chekupedzisira chechigadzirwa, kugadziriswa kwemaoko uye kugadzirisa ndiyo yakajairika mamiriro.

4. Kuderera kwekugadzirisa kushanda zvakanaka: Muchina wekucheka une zvimwe zvakanakira kucheka kwe synchronous uye chamfering yepombi dzakawanda, asi kucheka kwekucheka kwekuvhura kwepombi kwakanyanyisa kuderera, uye zvakakosha kushandura kona yekucheka uye nzvimbo yejecha resaha kune akawanda positioning uye kucheka, izvo zvisingabatsiri uye zvisingagoneki. Kudzora kururama. Punch presses inogona kushandiswa kubatch punching yemakomba echimiro akadai semakomba akatenderera nemakomba makomba. Zvisinei, kune marudzi akawanda emhando dzegomba muindasitiri yefenicha. Iyo punching muchina ine yakawanda yekugadzirisa kugona kwemakomba akadaro, kunze kwekunge mutengi achikonzera Pedza ruzivo rwakawanda uye mutengo wekugadzira akasiyana molds akasiyana. Wese munhu anoziva kuti muchina wekuchera unogona kungogadzira makomba akatenderedza, uye kugadzirisa kwacho kunogumira. Izvo zvinogumira zvekugadzirisa uye kusakwana kwega kwega nzira kunokonzeresa kusakwana mune yakazara chigadzirwa kubuda.

5. Mutengo wepamusoro webasa: Kucheka, kurovera nekuchera mumagariro ekugadzirisa maitiro, chinhu chikuru ndechekupindira kwevanhu. Kushanda kwemudziyo wega wega kunoda kuchengetedzwa nemaoko, nekuti automation yemidziyo yakadai yakadzikira zvakanyanya. Nokuda kwekugadzirisa kwezvinhu zvakadaro zvisiri-mapepa ekugadzirisa zvinhu zvepombi, kutonga kwebhuku kunodiwa kune imwe neimwe chikamu chekudyisa, kuisa, kugadzirisa uye kutorazve. Naizvozvo, inogona kazhinji kuoneka mune fenicha yekugadzira indasitiri yemusangano, michina mizhinji, vashandi vazhinji. Mazuvano, nekuvandudzwa kwemamiriro emisika, varidzi vemabhizimisi vari kuchema-chema kuti vashandi vari kuramba vachingofamba-famba, uye zviri kuramba zvichinetsa kupinza basa. Zvido zvemihoro yevashandi zviri kuwedzerawo. Mari yevashandi inogona kuverengera chikamu chikuru chepurofiti yemakambani.

6. Hunhu husina kunaka hwechigadzirwa: Kururama uye kunaka kwepombi yakapedzwa inobata zvakananga chigadzirwa chekupedzisira. Burr, peripheral deformation yemuchina, tsvina pamadziro emukati wepombi, nezvimwewo hazvibvumirwe kugadzira fenicha yepamusoro. Zvisinei, kungave kuri kucheka muchina wekucheka, kubaya, kana kuchera, hapana mubvunzo kuti matambudziko aya anozoburitswa mushure mekugadzira pombi. Kubvisa nemaoko, kugadzira, uye kuchenesa basa mumabasa anotevera hazvigone kudzivirirwa.

7. Pane kushayikwa kwakakomba kwekushanduka-shanduka: Mazuva ano, kudiwa kwevatengi kuri kuramba kuchiwedzera kumunhu, saka ramangwana rekugadzira fenicha rinonyatsowedzera uye rinowedzera munhu mumwe nomumwe. Muchina wechinyakare wekuchekesa, muchina wekubaya, muchina wekuchera uye zvimwe zvekushandisa ndezvechinyakare, uye hunyanzvi hwekuita haugone kutsigira dhizaini nyowani uye kurudziro yekugadzira. Kupenya muchokwadi. Iko kusashanda, kuderera kwemhando, uye kudhura kwakanyanya kwekukanganisa kwechinyakare kugadzirisa modhi kuchakanganisa zvakanyanya kumhanya kwekutsvaga nekuvandudza zvigadzirwa zvitsva, uye kupa musika kutanga.

Ndezvipi zvitsva zvinogona kuunza zvizere otomatiki laser pombi cutter kune fenicha

indasitiri yekugadzira? Ndeapi maitiro emidziyo?

1. Simba idzva guru mukugadzirisa bismuth metal pombi: fiber laser cutting chombo chitsva chekugadzirisa simbi mumakore achangopfuura. Gare gare, zvishoma nezvishoma yave kutsiva kugera kwechinyakare, kuboora, kuboora uye kusaha. Iyo pombi zvinhu zvakare simbi, uye iyo fenicha indasitiri pombi inogadzirwa nesimbi isina tsvina, iyo inoenderana nezvakanakira fiber laser yekucheka. Fiber laser yakakwirira-inoshanda photoelectric shanduko inoshanda, yakanakisa danda mhando, yakakwirira yakatarisana density laser simba, yakanaka yekucheka gap, inogona kushandiswa muindasitiri yefenicha pombi kugadzirisa. Iyo inotenderera chuck yeVexo laser yakazara otomatiki fiber laser yekucheka muchina ine inotenderera yekumhanya inosvika zana nemakumi maviri rpm, uye kugona kwefiber laser kucheka simbi isina tsvina panguva yekupedzisira-yakanyanya kumhanya. Iko kusanganiswa kwezviviri kunoita kuti pombi yekugadzirisa ibudirire hafu yekuedza. Panguva imwecheteyo, kana iyo fiber laser inocheka pombi, iyo laser yekucheka musoro haibatike pombi, asi laser-inofungidzirwa pamusoro pepombi yekunyunguduka uye kucheka, saka ndeyeiyo isiri-yekubata yekugadzirisa maitiro, zvinobudirira kudzivirira dambudziko repombi deformation pasi pechinyakare kugadzirisa modhi. Chikamu chakachekwa nefiber laser chakachena uye chakatsetseka, uye hapana burr mushure mekucheka. Naizvozvo, iwo maviri mabhenefiti ekubudirira uye mhando ndiyo vimbiso yakakosha yefiber laser yekucheka kuti ive iyo nyowani huru simba musimbi pombi kugadzirisa.

2. Customized configuration kuti ibatsire kushandiswa kwekugadzirisa uye kukwidziridzwa kwehutano: kune indasitiri yefenicha, zviduku, zvakaonda, zvinhu zvinonyanya kushandiswa kwesimbi isina tsvina, tinoshandisa gadziriro yakanangidzirwa kuti tivandudze kushandiswa kwekugadzirisa uye kushandiswa kwehutano hwepombi yefesitiri yepombi. Special module fiber laser, yakakosha fiber, isiri-yakajairwa yakatarisana kureba fiber laser yekucheka musoro, zvese zvakanaka zvekugadzirisa zvinotarisa pakugona kwekucheka kwepombi yakakosha muindasitiri yefenicha, kushanda kwepombi yesimbi isina tsvina yemhando imwechete inotemwa neyedu yakajairwa standard fiber laser yekucheka muchina Inenge 30%, uku ichiunza zvirinani kucheka mhedzisiro.

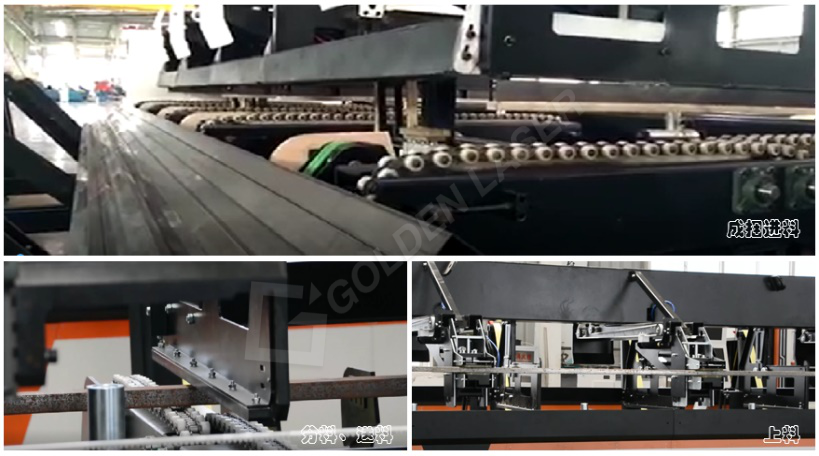

3. Batch otomatiki kugadzirwa kwepombi: Mushure mekunge mapaipi akasungwa akaiswa mumushini wekudyisa otomatiki, bhatani rimwe rinotangwa, uye mapaipi anopihwa otomatiki, akapatsanurwa, anodyiswa, anosungirirwa otomatiki, kudyiswa, kucheka uye kuburitswa mune imwe kuenda. Kutenda kune yedu otomatiki kurodha uye kurodha basa rakagadzirwa pane yakazara otomatiki laser pombi yekucheka muchina, pombi inogona kuona mukana webatch kugadzirisa. Zvigadzirwa zviduku zvepombi muindasitiri yefenicha zvinotora nzvimbo shoma. Mhando imwechete yemidziyo inogona kutakura mamwe mapaipi mumutoro mumwe, saka ine zvimwe zvakanakira. Munhu mumwe chete ari pabasa, uye basa rose rinopedzwa otomatiki. Uyu ndiwo mufananidzo wekushanda.

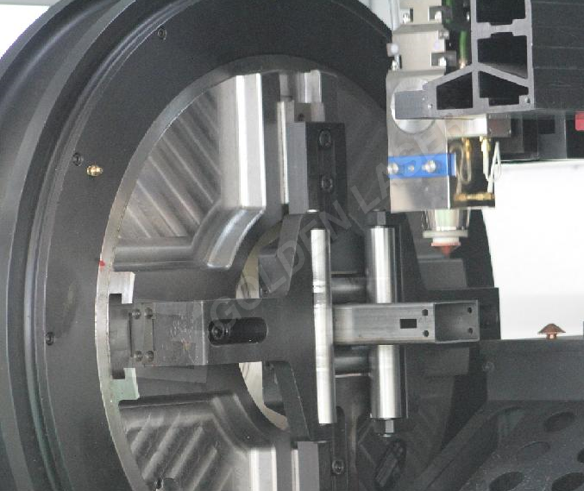

4. Tube clamping kuzorora: Kune diki chubhu yeindasitiri yefenicha, iyo laser yekucheka chuck yakanyanya kuomarara. Kana iyo clamping simba rakakura kwazvo, pombi inoremara nyore, iyo clamping simba idiki, uye urefu hwepombi hwakareba. Munguva yekucheka, pombi inotenderera pahupamhi hwepamusoro uye inobviswa nyore nyore. Naizvozvo, iyo clamping simba yechuck yepombi yekucheka midziyo muindasitiri yefenicha inofanirwa kuchinjika, uye nzira yekubvisa inofanirwa kuitika nyore. Iyo yekuzvimiririra pneumatic chuck yakagadziridzwa neyakakwana otomatiki laser pombi yekucheka muchina inogona kuona yekuzvimiririra mupombi clamping, kamwe iri munzvimbo yekumanikidza, uye pombi yepakati iri panzvimbo kamwe. Panguva imwecheteyo, simba reiyo chuck clamping rinotorwa kubva kumhepo yekupinza mhepo. Mutsara wekuisa gasi wakashongedzerwa negasi rinodzora vharafu, uye iyo clamping simba rinogona kugadziridzwa zviri nyore nekutenderedza knob pamhepo inodzora vharafu.

5. Inoshanda uye yakavimbika simba rekutsigira kugona: Iyo yakareba iyo pombi kureba, zvakanyanya kukomba deformation yepombi mushure mekunge yamiswa. Mushure mokunge pombi yakatakurwa, kunyange zvazvo chuck yakasungirirwa isati yasvika uye shure, chikamu chepakati chepombi chichanyunguduka nekuda kwesimba rinokwevera pasi, uye kutenderera kwepamusoro kwepombi kuchava mafungiro ekusvetuka, saka kucheka kuchakanganisa kunyatsocheka kwepombi. Kana iyo yakajairwa manyorerwo ekugadzirisa nzira yekutsigirwa kwezvinhu zvepamusoro yakagamuchirwa, chete zvinodikanwa zvekutsigira zvepombi yakatenderedza uye pombi yakaenzana inogona kugadziriswa, asi nekuda kwekucheka kwepombi yemhando yechikamu chisina kujairika senge rectangular pombi uye elliptical pombi, kugadziridzwa kwemanyorero kweiyo yepamusoro zvinhu kutsigirwa hakuna kukodzera. . Naizvozvo, iyo inoyangarara yepamusoro tsigiro uye muswe tsigiro yemidziyo yedu yekumisikidza inyanzvi mhinduro. Apo pombi inotenderera, icharatidza maitiro akasiyana-siyana munzvimbo. Iyo inoyangarara yepamusoro yezvinhu tsigiro uye muswe wezvinhu tsigiro inogona kugadzirisa otomatiki urefu hwekutsigira munguva chaiyo zvinoenderana nekushanduka kwepombi maitiro, saka inogona kuve nechokwadi kuti pasi pepombi inogara isingaparadzanisiki kubva kumusoro kwechitsigiro shaft, iyo inoridza tsigiro ine simba yepombi. effect. Iyo inoyangarara yekumusoro zvinhu tsigiro uye inoyangarara zvinhu zvemuswe tsigiro inoshanda pamwe chete kuchengetedza kumira kwepombi pamberi uye mushure mekucheka, nekudaro kuve nechokwadi chekucheka chaiko.

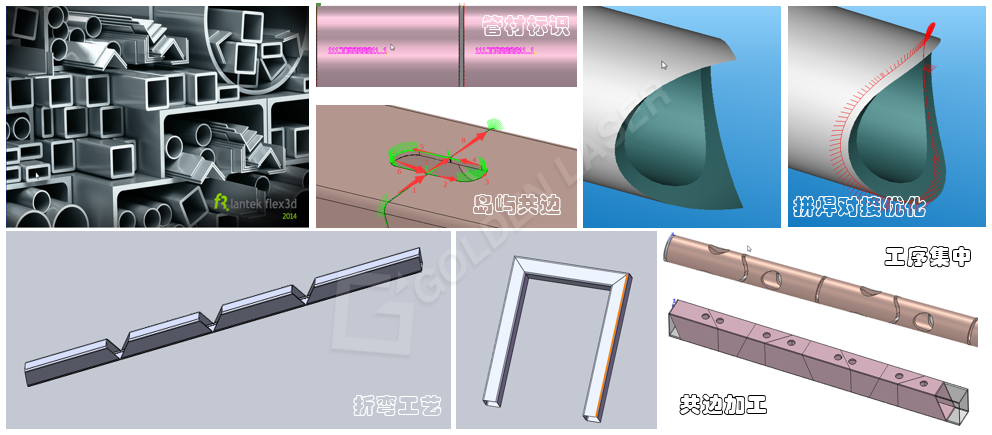

6. Maitiro ekugadzirisa uye maitiro akasiyana-siyana: shandisa 3D yekudhirowa software kugadzira mapatani akasiyana-siyana anoda kugadziriswa, akadai sekucheka-kubvisa, beveling, kuvhura, notching, kuisa chiratidzo, nezvimwewo, uye wozoashandura kuva NC machining zvirongwa mune imwe nhanho kuburikidza nehunyanzvi nesting software. , inopinza kune inyanzvi CNC sisitimu yekumisikidzwa kwechishandiso, uye wozotora inoenderana yekucheka maitiro paramita kubva kune dhatabhesi rekuita, uye machining anogona kutangwa nebhatani rimwe. Iyo otomatiki yekucheka maitiro inopedzisa yechinyakare sawing, mota, punching, kudhirowa uye mamwe maitiro. Kupedzwa kwepakati kwemaitiro kunounza kudzoreka uye kuvimbiswa kugadzirisa kurongeka, pamwe nekushanda kwakanyanya uye mutengo wakaderera. Uku kuwedzera nekubvisa kwematambudziko arithmetic kunofanirwa kuve kwakajeka kune wese bhizinesi anoshanda.

7. Kushandiswa kwehunyanzvi faibha laser yekucheka michina yesimbi fenicha indasitiri mapaipi yakaunza shanduko nyowani kune pombi yekugadzirisa tekinoroji. Kubva patakatanga kutsvagisa nekusimudzira zvizere otomatiki fiber laser yekucheka muchina, takazvimisa pachedu muindastiri, tichiita kuti indasitiri iyi ive yakadzama, nyanzvi, uye nehungwaru. Indasitiri yesimbi yefenicha yakave muenzaniso kesi yemuchina wedu wekucheka pombi. Mumugwagwa weR&D, kuongorora uye hunyanzvi mumakore apfuura, takaunganidza ruzivo rwakawanda rwehunyanzvi uye takagadzira akawanda anoshanda uye ehunyanzvi hunyanzvi hweindasitiri yekugadzira fenicha. Process. Iyo yepakutanga inoda kusungirirwa, ikozvino inogona kusungwa uye kugadziriswa; iyo yepakutanga inoda kuve yakasanganiswa, inogona kubhenda zvakananga; iyo yepakutanga pombi kushandiswa kwakadzikira kwazvo, ikozvino inogona kushandisa yakajairika kumucheto yekucheka basa kuti iwane nani pombi yekuchengetedza uye zvimwe zvigadzirwa Kunze, uye zvichingodaro, idzi nzira nyowani dzekugadzirisa dzinoshandiswa muindasitiri yefenicha pombi yekugadzirisa kesi, uye zvikomborero ndezvechokwadi vashandisi vemidziyo yedu.

Laser Kucheka Machine For Metal Furniture