Tumira Kubvunza kune Itsva Robhoti Laser Kucheka Machine ruzivo uye Mutengo!

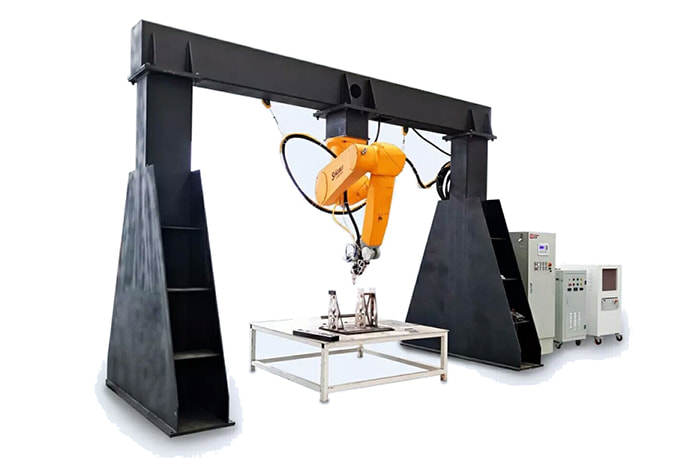

3D Laser Kucheka Machine

- Fiber Laser Cutter ine Robotic Arm System.

Robot 3D Laser Kucheka Machine Highlights

.

2. 6-axis linkage, basa rakasiyana-siyana, kusvika kureba, kutakura mutoro, inogona kuva munzvimbo yebasa ye 3D track yekucheka.

3. Compact, wrist slim, kunyangwe mumamiriro ezvinhu akaoma, zvirambidzo panzvimbo zhinji, zvinogona kuita basa repamusoro-soro.

4. Maitiro ekumhanya uye chinzvimbo anogona kugadziriswa, kuti awane yakanakisa kugadzira kwakaringana, goho rakakura, uye kukurumidza.

5. Mutsindo wakaderera, nguva yekugadzirisa nguva yakareba, hupenyu hurefu hwebasa

6. Iyo manipulator inogona kushandiswa kuburikidza neruoko

7. Nekugadzirisa purogiramu uye hardware shanduko, inogona kubudirira laser yekucheka, laser welding, kurongedza, kubata uye mamwe mabasa.

3D Laser Kucheka Machine Zvimiro

1.Laser source: kushandiswa kwepamusoro-kushanda IPG fiber lasers, kushanda kwepamusoro, mari shoma yekushandiswa kwakabatanidzwa.

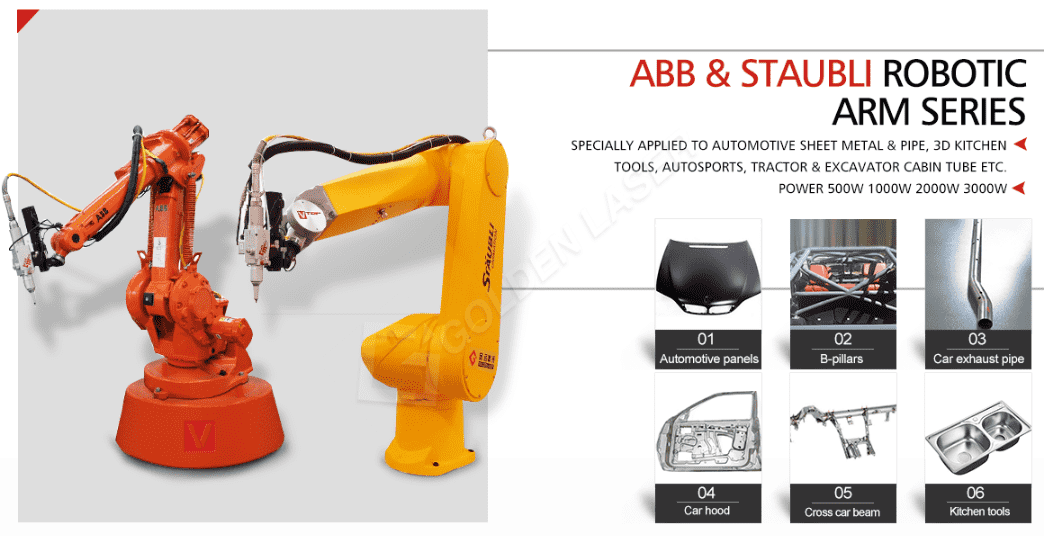

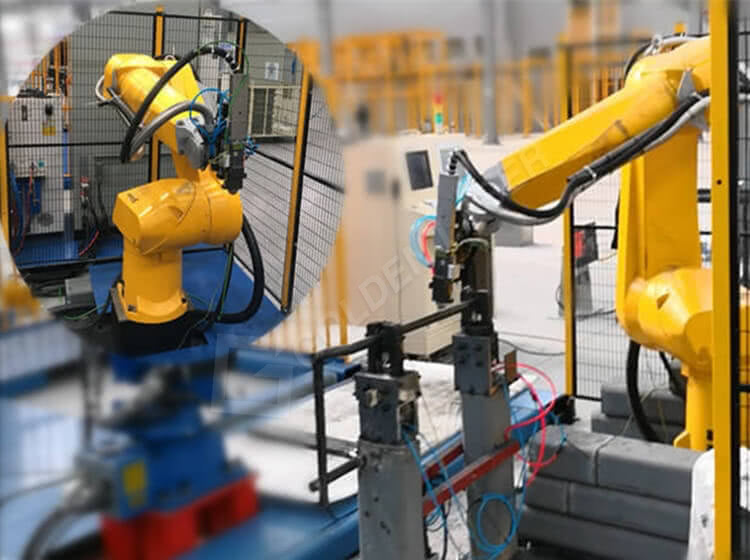

2.Kuitwa kweiyo laser yekucheka kweanoshanda masangano eSwiss Staubli robhoti. Staubli robhoti ndiro robhoti rakanyatsorongeka irobhoti. Kushandiswa kwealuminium titanium alloy robhoti muviri, harmonic reducer dhizaini, iro robhoti muviri unoenderana nemamwe mabhureki, huremu, kukurumidza, yakanyanya kurongeka. TL160L indasitiri marobhoti mune diki curvature yeyakachekwa yakanaka uye yakakura fomati yekuudza iyo laser yekucheka hama kune mamwe mabhureki ane mabhenefiti ari pachena. Mune yakakwirira-kumhanya laser yekucheka, iyo Staubli marobhoti system inogona kuwana kumhanya kwe18 m / min pasina jitter, mamwe mabhureki haawanzo kuvimbisa iyo laser yekucheka kumhanya kwe10 m / min kuti ive nechokwadi chekucheka mhedzisiro. Zvakare mudiki diki-rakachekwa, unogona kucheka dhayamita diki ye2mm diki kutenderera, yekucheka maitiro akatsetseka uye akanaka, ayo mamwe marobhoti eindasitiri asingakwanisi kuita.

3.Robhoti yeStaubli inogona kugadziriswa maererano nezvinodiwa chaizvo zvevatengi off-line programming software, software inogona kuverenga matatu-dimensional mapping software kwose kwose vda, igs, x_t, sldprt, prt, par uye mamwe mafomu, zvakananga mupurogiramu yepurogiramu yepurogiramu, Kudzidzisa, nyore uye inobudirira kuti uwane chigadzirwa chemhando yebasa rekugadzirisa.

4.Tevedza robhoti laser yekucheka musoro: sarudzo nemhando dzepasi rose dzepamusoro dze laser cutting head kuti uone kuti laser beam inogara iri munzvimbo yekutarisa kuti ive nechokwadi chekucheka.

5.Auxiliary air blowing system: iyo sisitimu inobatanidza kumanikidzwa kwemhepo, nitrogen, okisijeni matatu gasi sosi chimiro uye yakakwirira uye yakaderera voltage shanduko gasi nzira, mutengi anogona kusarudza zvinoenderana nekugadzirisa zvinodiwa zvemhando uye mutengo wegisi rinobatsira.

6.Lubrication system: The 3d laser cutting machine yakagadzirirwa ne manual lubrication system, kuderedza kupera kwezvikamu zvinofamba, kuve nechokwadi chekukurumidza kwerobhoti yese laser machine.

Robot Fiber Laser Kucheka Machine Kushanda Vhidhiyo

Robotic Arm 3D Laser Kucheka Machine pane Mutengi Saiti

Robotic Arm 3D Laser Kucheka Metal Tubes uye Metal Sheets Sample

Unoda Kuziva Rumwe Ruzivo nezve Robot Laser Cutter?

Material & Indasitiri Application

Inoshanda kune ese marudzi ese asina kuenzana simbi pombi uye sheet simbi laser yekucheka, yakakodzera indasitiri yemotokari, kugadzira mold, midziyo yekicheni, zvigadzirwa zvesimbi, senge otomatiki kucheka.

1. Zvemotokari pepa simbi yakavharwa uye chassis zvikamu uye mamwe mabheti ezvidiki zvidiki zvekugadzira, senge musika wekugadzirisa, marori, mabhazi, michina yekuvaka, yakagadziridzwa mota uye zvichingodaro.

2. Nekuchinjika kugadzirwa kwelaser yekucheka muchina, panzvimbo yekuvhurika stamping, yakakodzera kugadzirwa kwemunhu, asiwo kupfupisa kutenderera kwechigadzirwa, kukurumidza kupindura kumusika.

3. Nerobhoti laser cutting system, panzvimbo yekucheka plasma inobatwa nemaoko, inorerutsa zvikuru maitiro, asi zvakare yakatambudzwa nevashandi veplasma yemugadziri mukutarisira dambudziko.

4. Iyo yakazara yakaderera mutengo wemidziyo, kushandiswa kwemutengo wakaderera, kugona kwakanyanya, kumwe kupinza kunze kweshanu-axis laser yekucheka muchina, yakakosha kuchengetedza mumutengo wega yega workpiece.

5. Inokodzera fekitari inotambira inotsigira yekutanga batch diki, uye zvimwe zvigadzirwa kuti uwedzere kugadzirwa kwehuwandu mushure mekutsika kweforoma, kuvandudza mold kuderedza njodzi yekudyara.

Machine Technical Parameters

ABB2400 Robotic Arm Main Technical Parameters

| Huwandu hwematemo erobhoti | 6 | Yechitanhatu axis mutoro | 20Kg |

| Robotic crane | 1.45m | Yakadzokororwa chinzvimbo | 0.05mm |

| Kurema | 380Kg | Voltage | 200-600V, 50/60Hz |

| Simba rekushandisa | 0.58Kw | rated power | 4KVA/7.8KV |

| ABB 2400 Robot gantry yekucheka muchina tekinoroji paramita | |||

| Izvo zviyero zvese zvemidziyo | |||

| Floor space(mxm) | nezve 3 * 4.2 (kusanganisira chiller uye yakanyanya kudzvanywa mhepo yekuomesa system) | ||

| Worktable urefu | 350mm | Noise | <65 Db (kwete kusanganisira exhaust fan) |

| Simba rekupa zvinodiwa | AC220V±5% 50HZ (Simplex) | Total power | 4.5KW (Pasina mhepo) |

| Zvinodiwa zvezvakatipoteredza | Tembiricha yemhando: 10-35 ℃ Humidity range: 40-85% 1000 metres pazasi pegungwa, kushandiswa kwezvakatipoteredza pasina kupisa, kuputika, simba remagineti, kudengenyeka kwenyika kwakasimba. | ||

| Iwo makuru ma parameter eiyo laser sosi | |||

| Laser mhando | Fiber laser | ||

| Laser inoshanda | Kuenderera mberi / modulation | Laser simba | 700W (1000w 2000w 3000w sarudzo) |

| Spot mode | Multi-modhi | Laser wavelength | 1070nm |

| Auxiliary system | |||

| Kutonhodza system | Dual-temperature mbiri-pombi pombi ine yekuchenesa system chiller (yakasarudzika kumisikidzwa) | ||

| Laser source yekutonhora system | 350W yakatwasuka air conditioning (yakasarudzika gadziriro) | ||

| Inobatsira gasi system | Matatu gasi sosi mbiri-kumanikidza gasi (yakasarudzika kumisikidza) | ||

| Laser yekucheka musoro | Capacitive yekutevera kutarisa | ||

Zvigadzirwa zvinoenderana

-

RN16 / RN18 / RN26 (ABB X2400D/X2400L / Staubli XR160L)

Multifunction 3D Robot Laser Kucheka Machine Yesimbi Sheet uye Metal Tube Cheka -

VR16 / VR18 / VR24

Fiber Laser Robhoti Arm 3D Kucheka Tube uye Pipe For Auto Zvikamu -

RE16 / RE18 / RE26

Robhoti Laser Kucheka Machine Cell