In warshadaha processing laser maanta, goynta laser xisaabiyaa ugu yaraan 70% ee share codsiga in industry processing laser. Goynta laser waa mid ka mid ah hababka goynta horumarsan. Waxay leedahay faa'iidooyin badan. Waxay fulin kartaa wax soo saar sax ah, goyn dabacsan, farsamayn qaab gaar ah, iwm, waxayna xaqiijin kartaa goynta hal mar ah, xawaare sare, iyo hufnaan sare. Waxay xallisaa dhibaatada wax soo saarka warshadaha. Dhibaatooyin badan oo adag laguma xallin karo hababka caadiga ah ee habka.

Haddii loo qaybiyo agabka warshadaha baabuurta. Waxa loo qaybin karaa laba nooc oo ah hababka goynta laysarka: dabacsanaan aan bir ahayn iyo birta.

A. CO2 laser inta badan waxaa loo isticmaalaa in lagu gooyo walxaha dabacsan

1. Barkinta shilka ee baabuurta

Goynta Laserku waxay si hufan oo sax ah u gooyn kartaa barkinta shilka, waxay hubisaa isku xidhka barkinta shilka, hubinta tayada badeecada ilaa xadka ugu badan, waxayna u ogolaataa milkiilayaasha baabuurta inay si kalsooni leh u isticmaalaan.

2. Gudaha baabuurta

Laser-goy barkimo dheeraad ah oo fadhiga, daboolida fadhiga, roogagyada, suufka madaxa weyn, daboolka biriiga, daboolada qalabka, iyo qaar kaloo badan. Alaabooyinka gudaha baabuurka waxay ka dhigi karaan baabuurkaaga mid raaxo leh oo sahlan in la kala furfuro, la dhaqo, oo la nadiifiyo.

Mashiinka goynta laser-ka ayaa si dabacsan oo degdeg ah u jari kara sawirada iyadoo loo eegayo cabbirrada gudaha ee moodooyinka kala duwan, taas oo labanlaabaysa waxtarka wax soo saarka.

B. Fiber laserwaxaa inta badan loo isticmaalaa farsamaynta walxaha birta ah.

Aynu ka hadalno habka processing ee goynta laser fiber in warshadaha wax soo saarka jir baabuurta

Cabbirka goynta waxaa loo qaybin karaa jarista diyaaradda iyo goynta saddex-geesoodka ah. Qaybaha qaabdhismeedka birta ee xoogga badan, goynta laysarka shaki la'aan waa habka ugu wanaagsan ee goynta, laakiin jaangooyooyinka adag ama sagxadaha adag, iyada oo aan loo eegin dhinaca farsamada ama dhaqaalaha, goynta laser-ka ee gacanta robotka 3D waa hab wax ku ool ah oo wax ku ool ah.

Baabuurtu waxay sii wadaan inay sii socdaan oo ay sii socdaan wadada miisaanka khafiifka ah, iyo codsiga birta xoogga badan ee heerkulbeegga ah ayaa noqonaysa mid aad u ballaaran. Marka la barbardhigo birta caadiga ah, way ka fudud tahay wayna ka sii dhuuban tahay, laakiin xooggeedu wuu sarreeyaa. Waxaa inta badan loo isticmaalaa qaybaha kala duwan ee muhiimka ah ee jirka baabuurka. , sida alwaax ka-hortagga isku dhaca albaabka baabuurka, bambarrada hore iyo gadaal, A-pillar, tiir B, iwm, ayaa ah qodobbada muhiimka ah si loo xaqiijiyo badbaadada gaadiidka. Birta xoogga badan ee kulul ee la sameeyay waxaa lagu sameeyay shaabad kulul, iyo xoogga daaweynta ka dib waxaa la kordhiyaa min 400-450MPa ilaa 1300-1600MPa, taas oo 3-4 jeer ka badan birta caadiga ah.

Marxaladda wax soo saarka tijaabada dhaqameed, shaqada sida gooynta geesaha iyo goynta goynta qaybaha shaabadda waxaa kaliya oo lagu samayn karaa gacanta. Guud ahaan, ugu yaraan laba ilaa saddex hab ayaa loo baahan yahay, caaryadana waa in si joogto ah loo horumariyo. Saxnaanta qaybaha goynta lama dammaanad qaadi karo, maalgashigu waa weyn yahay khasaaruhuna waa dhakhso. Laakiin hadda wareegga horumarinta moodooyinka ayaa sii yaraanaya oo sii yaraanaya, shuruudaha tayada ayaa sii kordhaya oo sarreeya, wayna adagtahay in la isku dheelitiro labadaba.

Mashiinka goynta laser-ka ee saddex-geesoodka ah wuxuu dhamaystiri karaa habka jarista iyo feerida ka dib marka bannaanka, calending, iyo qaabeynta daboolka la dhammeeyo.

Aagga kuleylku saameeyay ee goynta laysarka fiber-ka waa mid yar, jeexitaanku waa siman yahay oo aan burr lahayn, waxaana si toos ah loo isticmaali karaa iyada oo aan la soo saarin habka xiga ee la jeexay. Sidan oo kale, baalal baabuur oo dhammaystiran ayaa la soo saari karaa ka hor inta aan la dhammaystirin dhammaystirka caaryada, iyo wareegga horumarinta ee alaabta baabuurta cusub waa la dardargelin karaa.

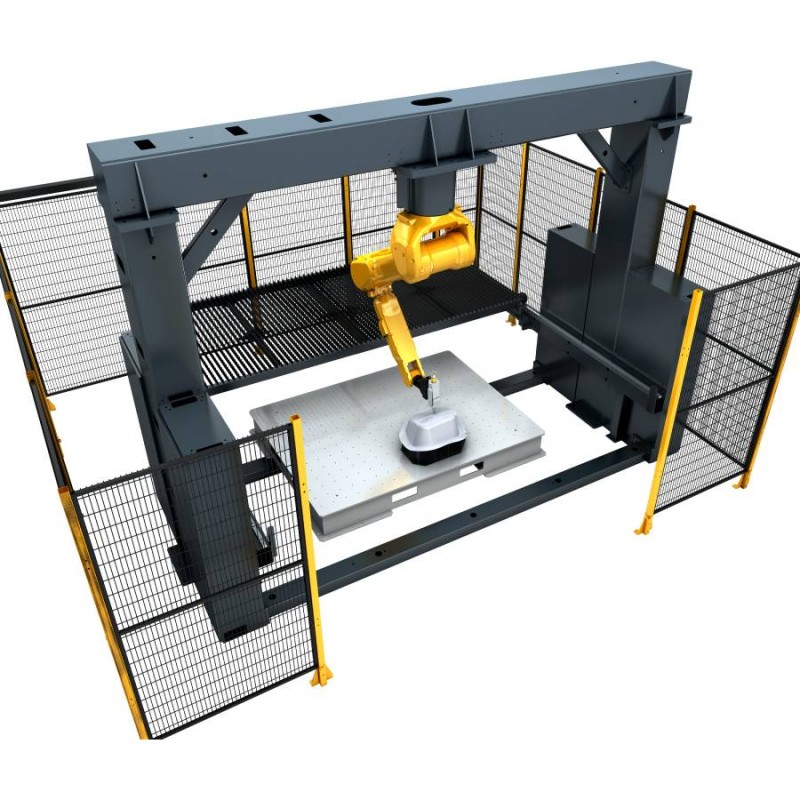

3D Robot Laser Goynta Machine Codsiga Warshadaha.

Goynta Laser ayaa si dhakhso ah u qabsaday suuqa iyada oo leh faa'iidooyinkeeda aan la barbar dhigi karin sida saxda ah, xawaaraha, waxtarka sare, waxqabadka sare, qiimaha hoose, iyo isticmaalka tamarta yar, waxayna noqotay qalabka lagama maarmaanka ah ee warshadaha baabuurta, waxaana si ballaaran loo isticmaalaa qaybo waaweyn oo farsamaynta, baabuurta, hawada hawada, farsamaynta dufcadaha yaryar iyo noocyada noocyada warshadaha, warshadaynta mishiinnada, warshadaynta warshadaha, warshadaha warshadaha qaybaha, iyo alaabta cad, iyo habaynta Dufcaddii ee qaybaha biraha kulul-sameeyey.

Fiidiyowga Goynta Laser-ka ee Khadka Warshadaha Baabuurta

La Xiriira Fiber Laser Cutter

Mashiinka Goynta Xashiishka Laser-ka

In ka badan 10KW Fiber Laser Goynta Mashiinka Goynta Fudud ee Jaran khafiifa iyo Dhumucdiisuna tahay Naqshad kasta oo adag.

Tube Laser Machine Goynta

Iyada oo la raacayo kontaroolaha PA CNC iyo Lantek Nesting Software, way fududahay in la gooyo tubooyinka qaababka kala duwan. Madaxa Goynta 3D Way fududahay in la gooyo tuubo 45-degree ah

Robot Laser Machine Goynta

3D Robot Laser Goynta Kor ama Hoos Habka Koritaanka ee Goynta Jirka Baabuurta ee cabbirka kala duwan.