U dir Weydiinta Macluumaadka Mashiinka Goynta Laser-ka ee Robot-ka ugu cusub iyo Qiimaha!

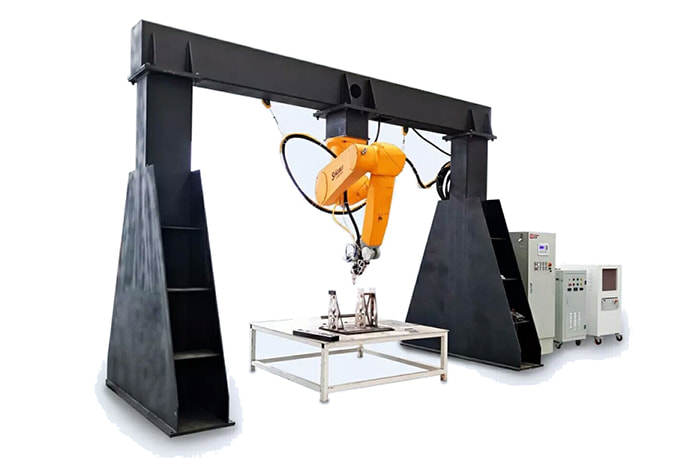

3D laser Goynta Machine

- Fiber Laser Cutter oo leh nidaamka gacanta Robotic.

Robot 3D Laser Goynta Mashiinka Goynta Muhiimka ah

1. XR160L ee shirkadda aan meelaynta xaashida xaashida baabuurta warshadaha-gaar ah robot, qalabka by Stäubli RX160L nidaamka robot, IPG500W fiber laser, madaxa laser LASERMECH (oo ay ku jiraan habka dhaqdhaqaaqa), miiska meelaynta, qaboojiyaha, ammaanka iyo qaybaha kale ee asaasiga ah.

2. Xidhiidhka dhidibka 6-aad, shaqo balaadhan oo kala duwan, ilaa masaafo dheer, awoodda xajinta, waxay ku jiri kartaa goobta shaqada ee jarista 3D.

3. Is haysta, cudud caato ah, xitaa xaaladaha adag, xaddidaadaha meelo badan, wali waxay gaari karaan hawlgal heersare ah

4. Xawaaraha geedi socodka iyo meelaynta waa la hagaajin karaa, si loo gaaro saxsanaanta wax soo saarka ugu fiican, wax soo saarka sare, iyo xawaaraha sare.

5. Sawaxanka hooseeya, muddada u dhaxaysa dayactirka joogtada ah waa mid dheer, nolol adeeg oo dheer

6. Manipulator-ka waxa lagu maamuli karaa meel gacanta lagu qaato

7. Iyada oo la beddelo barnaamijka iyo isbeddelada qalabka, waxay gaari kartaa goynta laser, alxanka laser, baakadaha, maaraynta iyo hawlaha kale

Tilmaamaha Mashiinka Goynta Laser 3D

Isha 1.Laser: isticmaalka wax-qabadka sare ee IPG fiber lasers, waxtarka sare, qiimaha hoose ee isticmaalka isku dhafan.

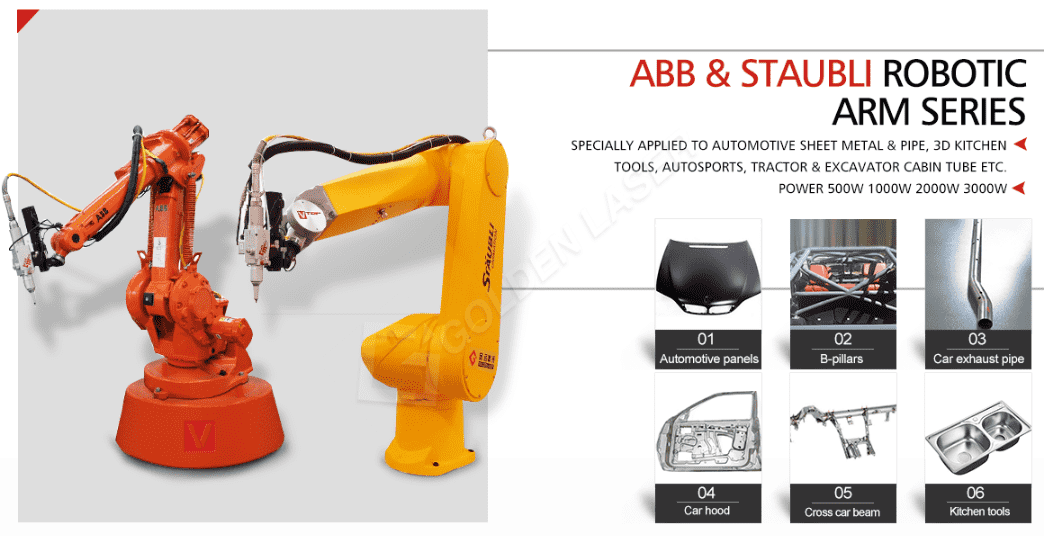

2.Fulinta jarista laysarka ee hay'adaha fulinta ee Robot Swiss Staubli. Robot Staubli waa robot-ka ugu saxsan ee warshadaha. Isticmaalka jirka robot-ka aluminium titanium alloy, nashqada dhimista harmonic, jirka robot marka loo eego noocyada kale, miisaanka fudud, xawaaraha sare, saxnaanta sare. Robots warshadaha TL160L ee curvature yar ee gooyay ganaax iyo qaab weyn si ay u sheegaan goynta laysarka marka loo eego noocyada kale waxay leeyihiin faa'iidooyin cad. Goynta laser-xawaaraha sare leh, nidaamka robots Staubli wuxuu gaari karaa xawaare dhan 18 m / min iyada oo aan jitter lahayn, noocyada kale marar dhif ah ayay dammaanad qaadaan xawaaraha goynta laser-ka ee 10 m / min si loo hubiyo natiijooyinka goynta wanaagsan. Sidoo kale in yar oo wareeg ah, waxaad gooyn kartaa dhexroorka ugu yar ee 2mm wareeg yar, goynta saamaynta siman oo qurux badan, kuwaas oo noocyada kale ee robots warshadaha ma samayn karaan.

Robot 3.Staubli waxaa loo habeyn karaa iyadoo loo eegayo baahiyaha dhabta ah ee macaamiisha barnaamijyada barnaamijyada ka baxsan khadka, softiweerku wuxuu akhrin karaa software-ka khariidaynta saddex-geesoodka ah meel kasta vda, igs, x_t, sldprt, prt, par iyo qaabab kale, si toos ah nidaamyada track compiler software, Waxbarashada, fudud oo hufan si loo gaaro wax soo saarka nooca shaqada barnaamijka.

4.Follow madaxa goynta laser-robot: ikhtiyaari leh noocyada ugu sarreeya ee caalamiga ah ee madaxa goynta laser si loo hubiyo in laydhka laysarka uu had iyo jeer ku jiro booska diiradda si loo hubiyo saameynta goynta.

Nidaamka afuufista hawada 5.Auxiliary: nidaamku wuxuu isku daraa hawada cadaadiska sare, nitrogen, oksijiinta saddex qaab-dhismeedka gaaska iyo dariiqa gaaska beddelka tamarta sare iyo hoose, macaamilka wuxuu dooran karaa iyadoo loo eegayo shuruudaha tayada processing iyo kharashka gaasta kaaliyaha.

Nidaamka 6.Lubrication: Mashiinka goynta laser-ka ee 3d wuxuu ku qalabaysan yahay nidaamka sifaynta buug-gacmeedka, hoos u dhig xirashada qaybaha dhaqdhaqaaqa, si loo hubiyo xawaaraha sare ee dhammaan nidaamyada robot-ka mashiinka laser.

Mashiinka Goynta Fiber Laser Fiber Fiber Fiidiyowga Shaqada

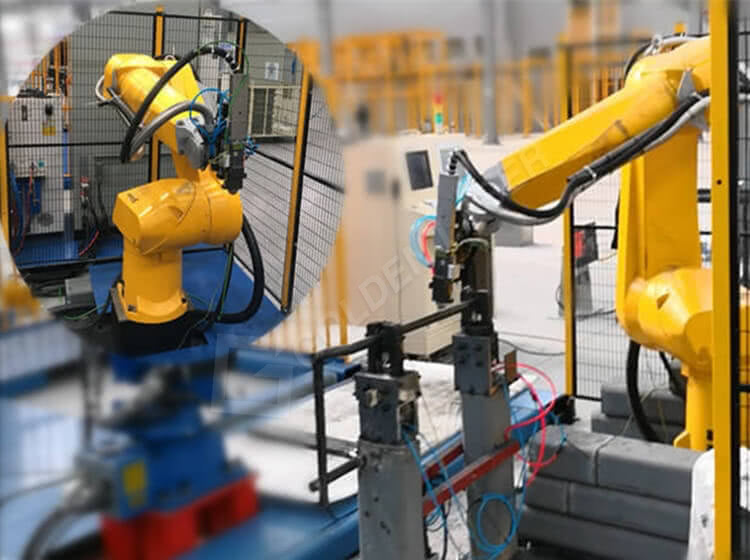

Robotic Arm 3D Laser Goynta Mashiinka Goynta ee Goobta Macmiilka

Robotic Arm 3D Laser Goynta Tuubooyinka Birta iyo Tusaalaha Xaashiyaha Biraha

Ma rabtaa inaad ogaato macluumaad dheeraad ah oo ku saabsan Robot Laser Cutter?

Qalabka & Codsiga Warshadaha

Lagu dabaqi karo dhammaan noocyada tuubooyinka birta ah ee aan sinnayn iyo goynta laser-ka xaashida, oo ku habboon warshadaha baabuurta, soosaarka caaryada, weelasha jikada, alaabada birta, sida goynta tooska ah.

1. Baabuurta dahaadhida birta ah iyo qaybaha chassis-ka iyo qaybo kale oo tiro yar oo wax soo saar ah, sida suuqa dayactirka, baabuurta xamuulka, basaska, mishiinada dhismaha, baabuurta la bedelay iyo wixii la mid ah.

2. Iyada oo wax soo saarka jilicsan ee mashiinka goynta laysarka, halkii laga heli lahaa shaabad furan, oo ku habboon wax soo saarka shakhsi ahaaneed, laakiin sidoo kale soo gaabin wareegga horumarinta alaabta, jawaabta degdega ah ee suuqa.

3. Nidaamka goynta laser-ka ee robot-ka, halkii laga isticmaali lahaa goynta balaasmaha gacanta, ayaa si weyn u fududaynaysa habka, laakiin sidoo kale waxaa lagu dhibay shaqaalaha plasma ee soo saaraha ee maaraynta dhibaatada.

4. Wadarta qiimaha jaban ee qalabka, isticmaalka qiimo jaban, hufnaan sare, soo dejinta kale ee shan-dhidibka laser goynta mishiinka, kaydka weyn ee kharashka workpiece kasta

5. Ku habboon warshadda martida loo yahay ee taageeraya sahayda dufcaddii yar yar ee hore, iyo alaabooyinka kale si ay u kordhiyaan awoodda wax soo saarka ka dib shaambada caaryada, horumarinta caaryada si loo yareeyo khatarta maalgashiga

Qiyaasta Farsamada Mashiinka

ABB2400 Robotic Arm Halbeegyada Farsamo ee Muhiimka ah

| Tirada faasas ee robotka | 6 | Culayska dhidibka lixaad | 20kg |

| wiishka robotiga ah | 1.45m | booska soo noqnoqda | 0.05mm |

| Miisaanka | 380kg | Voltage | 200-600V, 50/60Hz |

| Isticmaalka tamarta | 0.58Kw | awoodda lagu qiimeeyay | 4KVA/7.8KV |

| ABB 2400 Robot gantry goynta mashiinka cabbirada farsamada | |||

| Halbeegyada guud ee qalabka | |||

| Baaxadda sagxada (mxm) | qiyaastii 3 * 4.2 (oo ay ku jiraan qaboojiyeyaasha iyo nidaamka qalajinta cadaadiska sare ee hawada) | ||

| Dhererka la shaqayn karo | 350mm | Sawaxan | <65 Db (kuma jiraan marawaxada qiiqa) |

| Shuruudaha sahayda korontada | AC220V± 5% 50HZ (Si fudud) | Awoodda guud | 4.5KW (Hawo la'aan) |

| Shuruudaha deegaanka | Heerkulka kala duwan: 10-35 ℃ Inta u dhaxaysa qoyaanka: 40-85% 1000 mitir ka hooseeya heerka badda, isticmaalka deegaanka oo aan lahayn holac, qaraxyo, magnet xoog leh, dhulgariir xoog leh | ||

| Calaamadaha ugu muhiimsan ee isha laysarka | |||

| Nooca laser | Fiber laser | ||

| Laser ayaa shaqeeya | Joogtaynta / habaynta | Awoodda leysarka | 700W (1000w 2000w 3000w doorasho) |

| Qaabka barta | Qaabab badan | Dhererka hirarka leysarka | 1070nm |

| Nidaamka caawinta | |||

| Nidaamka qaboojinta | Bamka laba-heerkulka-laba-heerkulka leh oo leh nidaamka nadiifinta qaboojiyaha (qaabayn gaar ah) | ||

| Nidaamka qaboojinta isha laser | 350W qaboojiye toosan (qaabayn gaar ah) | ||

| Nidaamka gaasta kaaliyaha | Saddex il oo gaas ah gaas laba-cadaad ah (qaabayn gaar ah) | ||

| Madaxa goynta laser | Diiradda la-socoshada awoodda leh | ||

Alaabooyinka la xidhiidha

-

RN16 / RN18 / RN26 (ABB X2400D/X2400L / Staubli XR160L)

Multifunction 3D Robot Laser Machine Goynta Mashiinka Goynta Birta iyo Goynta Tuubada Birta -

VR16 / VR18 / VR24

Fiber Laser Robot Arm 3D Tube Goynta iyo Dhuumaha Qaybaha Gawaarida -

RE16 / RE18 / RE26

Unugyada Mashiinka Goynta Laser-ka ee Robot