| Nomoro ea mohlala | ke 25-3D / i 25A-3D / (P2560A-3D) |

| Bolelele ba tube | 6000mm, 8000mm ka boikhethelo |

| Bophara ba tube | 20-250mm / 20-350mm |

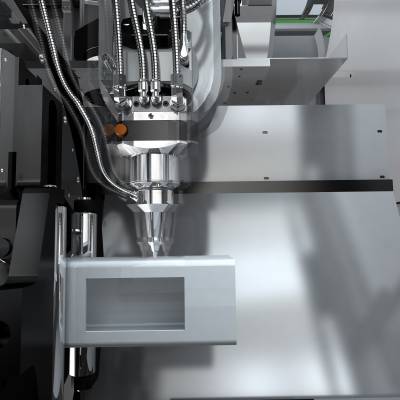

| Hlooho ea Laser | Hlooho ea 3D Tube Laser BLT / Golden Laser 3D hlooho bakeng sa Khetho |

| Mohloli oa laser | Fiber laser resonator IPG / N-Light / China Mohloli oa Laser Raycus / Max |

| Servo Motor | Yaskawa Bus Motor |

| Matla a mohloli oa laser | 3000w 4000w 6000w khetho |

| Ho nepahala ha boemo | ± 0.05 limilimithara |

| Pheta ho nepahala ha boemo | ± 0.03 limilimithara |

| Lebelo le potolohang | 130r/mots |

| Ho potlakisa | 1.2G |

| Boima ba Boima bo Botle bakeng sa Tube e le 'Ngoe | 225kg (Φ200mm*8mm*6000mm) |

| Ho poma lebelo | itšetlehile ka lintho tse bonahalang, laser mohloli matla |

| Phepelo ea motlakase | AC380V 50/60Hz |

| Auto tube Feeder | ke 25A-3D ho kenyelletsa le mochini o fepang tube oa koloi |

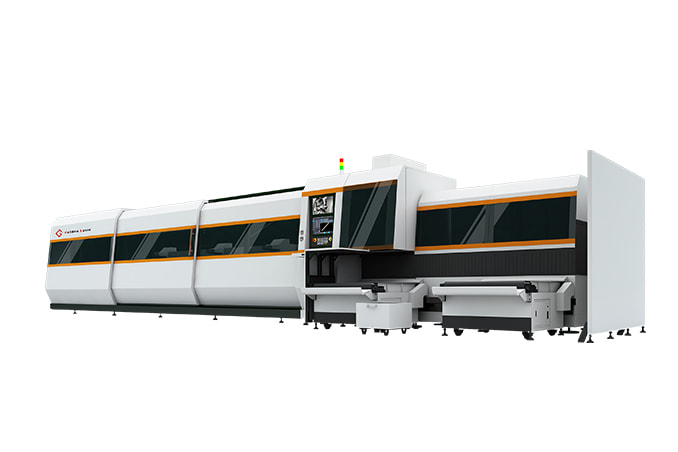

3D 5axis Fiber Laser Tube Cutting Machine - e nang le Rotary 3D Laser Cutting Head bakeng sa Tube Bevel Cutting..E loketse ho itšeha ka li-tubes tsa tšepe tse fapaneng, bophara ba tube e ka ntle e ka ba 20-350mm, bolelele ba tube ea tšepe 6meter. Ka Auto tubes bundle loading system for automatic tube laser cutting process.

Rotary3D Laser Cutting Head e Rekiloeng ho tsoa Jeremane

Bokhoni ba ho Cutting Groove ( Beveling Ability)

Bokhoni bo Khabane ba Groove Cutting ea Pipe End Surface

Etsa hore Pipe Splicing e be ntle le ho feta ka mor'a ho khaola.

Qoba ho Seha Seam Weld ea Pipe ka boeona (Ha ho ho Senyeha ha Li-tubes tsa Welding).

Lemoha ho seha ha Groove ha Libopeho tse fapaneng, joalo ka likoti tse Round le likoti tsa Square ho The Pipe Surface.

Bokhoni ba ho Bapisa ka ho Phethahetseng Phapang ea ho Kena lipakeng tsa Tube le The Finished Cutting.

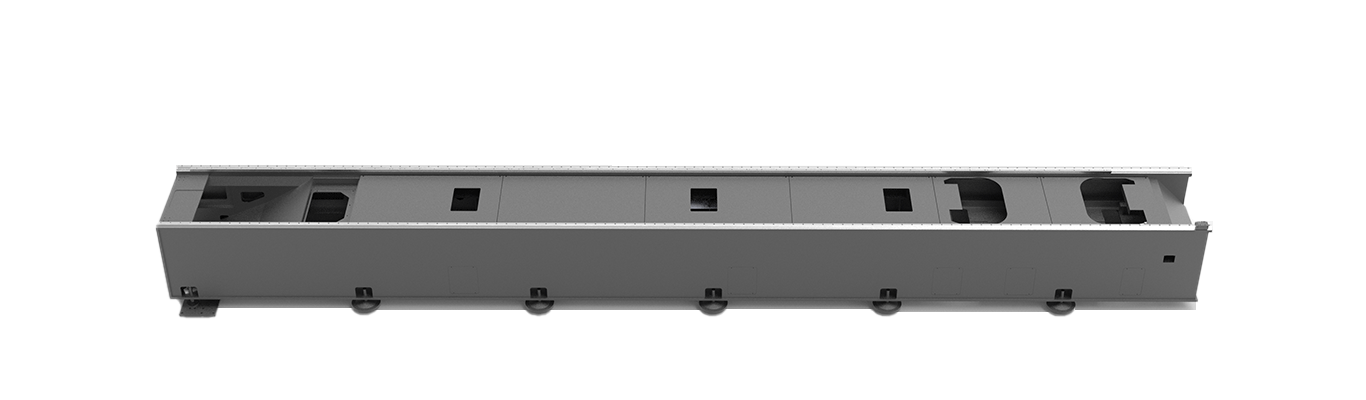

Sebopeho sa Mochini oa Ts'epe oa Tšepe oa Botenya bo felletseng:

'Mele oa mochine o tsitsitse, o na le nako e telele ea tšebeletso,' me ha o holofale habonolo.

Botenya ba poleiti ea welding ea sebopeho sa mochini ke ho fihlela ho25 limilimithara,

Mochini o le mong o boima ho fihlela7 lithane.

Sistimi ea Ts'ehetso ea Li-tubes tse phaphametseng

Sistimi ea morao-rao ea Ts'ehetso ea Phallisang e amohetsoe.

Sesebelisoa sa Tšehetso sa Servo Diameter Wheel

Lisebelisoa tse peli tse thusang tsa ho fepa le tse bohareng li hlophisitsoe haufi le li-chucks tse ka pele ho netefatsa hore bohareng ba tube

Setsebi se ikemetseng sa Pneumatic Chuck Clamping System

Chuck e entsoe ka thepa e phahameng ea tšepe, e nang le ts'ebetso e phahameng ea ho tiisa le ts'ebetso e ntle e matla.

Chuck e bohareng e kentsoe ka mokhoa o mocha ka har'a foreimi ea ho lahla mme e kopantsoe le 'mele o ka sehloohong oa sebopeho sa mochini.

Ha ho na tlhoko ea ho lokisa boemo ba mohlahare bakeng sa clamping e felletseng ea stroke.

Boholo ba ho koala matla a chuck keho fihlela ho 300kg, e leng 25% e phahameng ho feta moloko o fetileng oa li-chucks.

Lebelo le phahameng le ka fihla130r/mots.

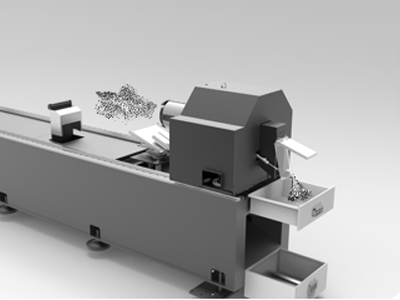

Ho ntšoa ha Lerōle la Mohatla

Karohano ea Lerōle le Mosi

Tsela e entsoeng ka nepo ea ho ntša lerole e tšoara le ho ntša lerōle le mosi tse bokelletsoeng karolong e ka morao ea clamping nakong ea ho itšeha. Ka mor'a ho sebetsoa ke sesebelisoa se phahameng sa ho sefa, lerōle le litšila tse ntle tsa slag li arotsoe ka nepo 'me li lahleloa ka lebokoseng la pokello ka fensetere ea ho ntša ka morao bakeng sa ts'ebetso e latelang.

Sena ha se tiise feela hore nako e telele ea ho ntša lerōle e sa tsitsang, empa hape e ntlafatsa haholo tšireletso le tšireletso ea tikoloho ea tlhoekiso ea mosi.

Sebopeho sa Moqomo

Mohatla o Mokhuts'oane oa Tube

Letlapa le ka morao le nka moralo oa sebopeho sa cannon-barrel 'me le tsamaisana le li-clamping clamping tse matla, tse sa ntlafatseng feela ho tiea ha clamping, empa hape li netefatsa botsitso le ho nepahala nakong ea ho itšeha ka lebelo le phahameng.

Ho phaella moo, moralo ona o lumella clamp ka morao hore e kene habonolo ka hare ho clamp e ka pele, e leng ho eketsang ho ba haufi le hlooho ea ho itšeha ka laser, ka tsela eo ho finyella ho itšeha ho nepahetseng ha thepa e khutšoanyane ea mohatla le ho ntlafatsa tšebeliso ea lintho tse bonahalang.

Flexible Pipe Clamping

E tsitsitseng le ea Tšepahala

The e ikhethang serrated holim tshebetso ya mehlahare haholo ntlafatsa clamping adhesion pakeng tsa phala le lintho tse bonahalang, ka katleho thibela phala ho tloha ho thella nakong ea clamping tshebetso, le ho ntlafatsa ho nepahala le polokeho ea ho itšeha.

Karolo e ka morao ea clamping e ts'ehetsa mekhoa e 'meli e feto-fetohang ea pipe clamping. Bakeng sa liphaephe tse nyenyane tsa bophara, mokhoa oa ho koala ka ntle o sebelisoa ho netefatsa hore ho na le matla a tšoanang le a tsitsitseng a clamping; bakeng sa liphaephe tse kholo tsa bophara, mokhoa oa ho tšehetsa ka ntle o ka khethoa ho etsa hore clamping e be e tsitsitseng le e ka tšeptjoang.

Sesebediswa se Amohelang Tube e Ikemetseng

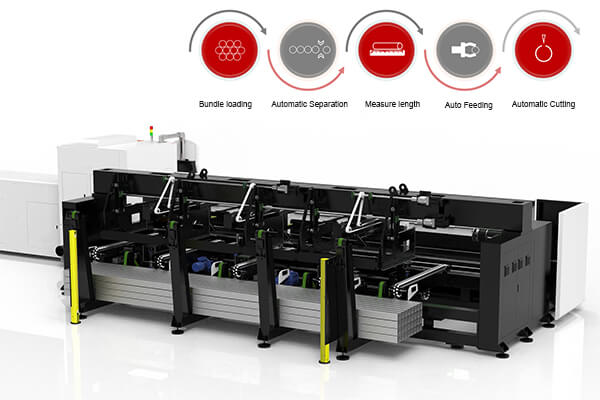

Auto Bundle Loading System

-Ntlafatsa Bokhoni ba Tlhahiso

The Automatic Loading System Lemoha The Automatic Continuous Production, is Haholo-holo Bakeng sa Tlhokahalo ea Tlhahiso ea Boima.

Sistimi ea phepelo ea li-tubes e loketse ho kenya liphaephe tsa 800 * 800mm. Ka ts'ebetso ea ho lekanya othomathike ho netefatsa ho kenya phala e nepahetseng ntle le phoso. Sistimi ea temoso ea alamo e hopotsa opareitara nakong ea tlhahiso eohle, molaoli oa PLC oa sistimi ea jarolla ka ho iketsa e bonolo ho e lokisa ho latela tlhoko ea ts'ebetso ea lintlha,Autoloading, Khetho ea hau e ntle ka ho fetisisa bakeng sa mochini o sehang oa bevel bakeng sa liphaephe...

Video ea Mochini oa ho Seha oa 3D Tube Laser

_

Ka Sephetho sa Beveling Welding

Mehlala Bapisa

_

Pakeng tsa Mochini oa ho Seha oa 3D Pipe Bevel bakeng sa Li-Tubes le Mochini o Tloaelehileng oa 2D Laser Tube Cutting bakeng sa Liphaephe

Sephetho sa 3D Laser Tube Cutting

Bapisa Le

Sephetho sa 2D Laser Tube Cutting

Sesebelisoa sa Material & Indasteri

Sesebelisoa sa 3D Laser Tube Cutting:

Haholo-holo bakeng sa ho khaola li-angle tsa tube, 45-degree angle cutting bakeng sa Channel Steel, I-beam joalo-joalo.

3D laser tube cutting e sebelisoa haholo ka mechine e boima, Shipbuilding, indasteri ea kaho joalo-joalo.

Mechini ea Teknoloji Parameters

Lihlahisoa tse amanang

-

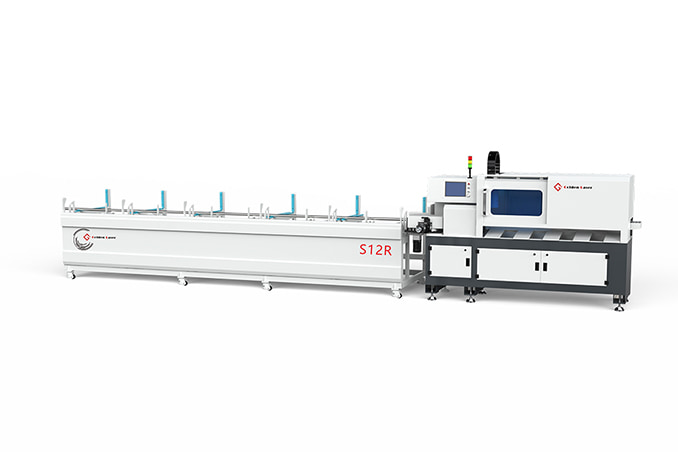

S12R

Top Rated Fiber Laser Round Tube Cutting Machine For Sale -

E3 E4 E6 E8 (GF-1530)

Ho kenya mahala Mochini oa ho Seha oa Fiber Laser -

GF-1530JHT (3)

Mochini o Koetsoeng oa Metal Sheet le Tube Laser Cutting Machine