Lits'ebeletso tsa khauta tsa khauta oaser li-adopts tsa pnc tsa rayto mas

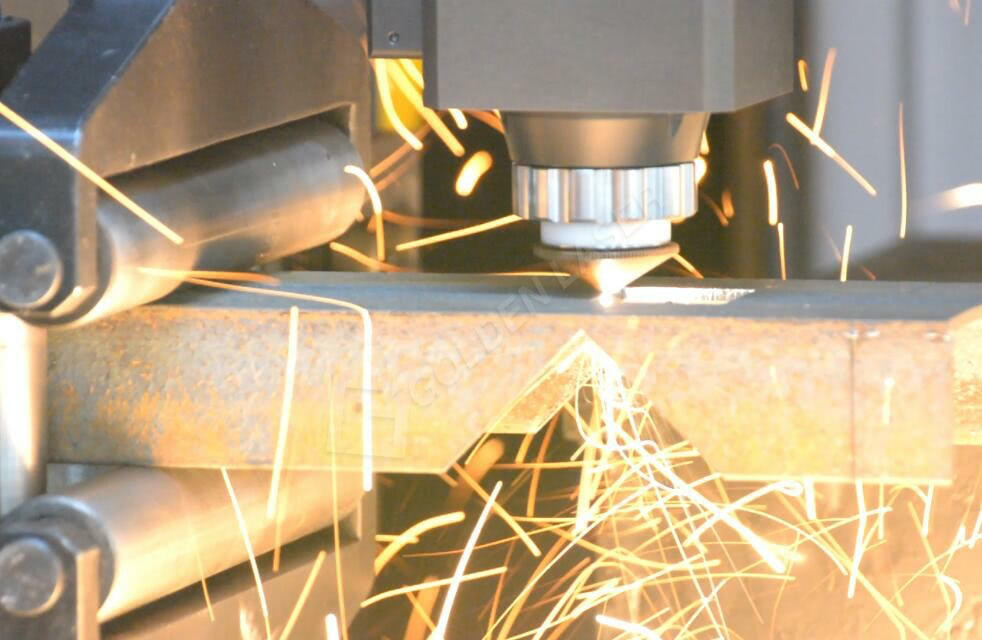

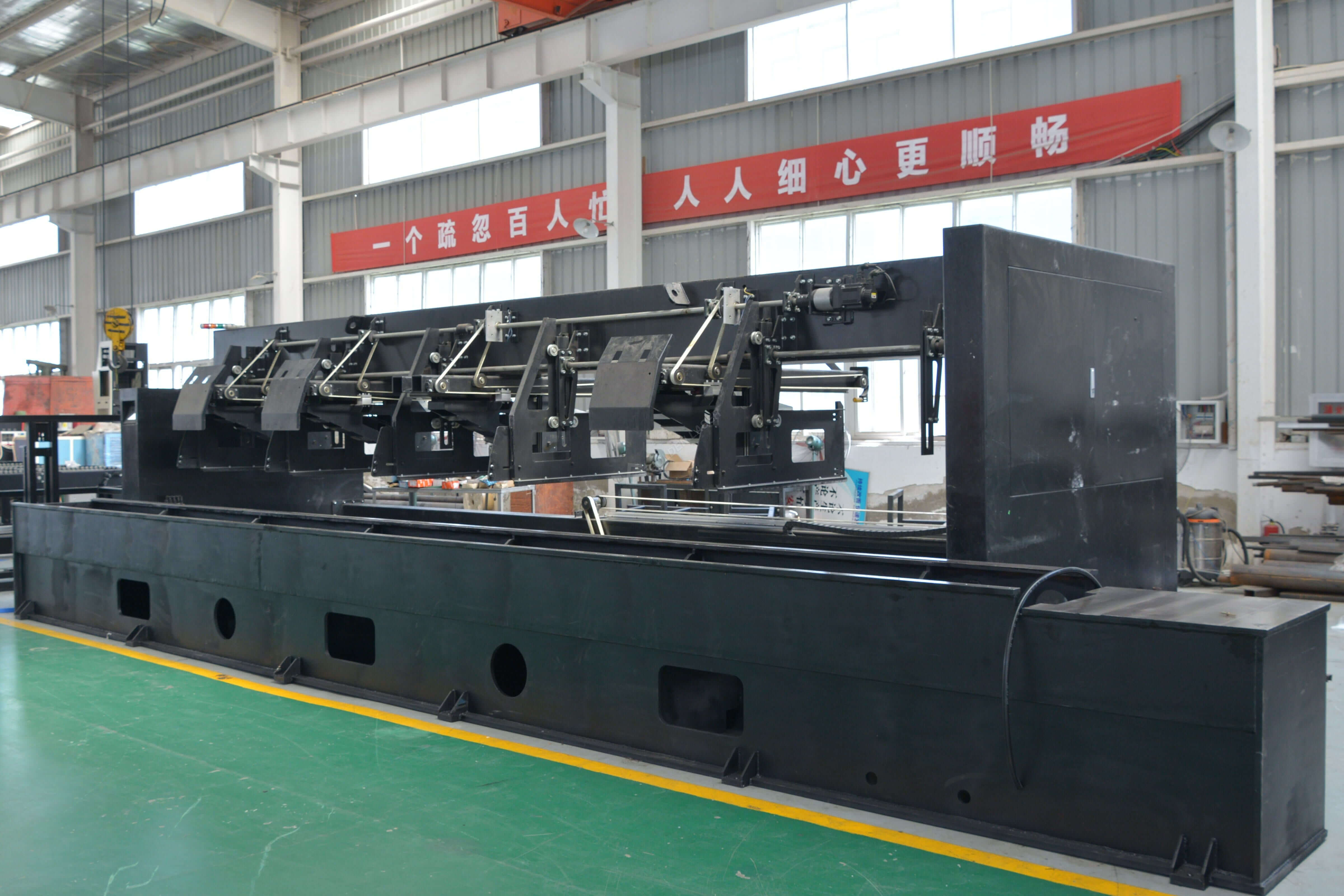

Kamora hore mocheso o phahameng o behang le ho boloka mokhoa o moholo oa CNCE CNing oa CNCing, o na le thata ho thata le ho tsitsa. Ka ho amohela likarolo tse tsoang holimo tse bolokiloeng, joalo ka koloi e tataisang, Barity-Stor, mochini o matla haholo, mochini o ratoa haholo ke 'marakeng kapa o pharaletseng.

1. Bolelele ba lipeitoana bo tlase bo tlase bo ka har'a 20mmm, e sutumetsang meeli.

2.To CCN Pipe Laser le ho sebetsa ebile ho sebetsa, opereishene e le 'ngoe e ka laola mechine e' meli ka nako e le 'ngoe,' me basali ba ka e sebelisa hape. Ka ho laola lintho tse matla, ho bonolo ho qala ho qala le ho emisa; Kamora hore pope e sehiloe ea pompo e phethoa, mochini o tla emisa ka bohona, 'me liphaephe tse felisitsoeng li lebokoseng la pokello.

3.TWIce vibration ea ho tsofala le ho kopanya ho netefatsa mochini o nang le botsitso bo botle le anti-share, ka hona, ho tla nka lilemo tse 15.

4. Ho kenya lisebelisoa tsohle ho amohela lisebelisoa tsa pheletso e phahameng joalo ka lisebelisoa tsa ho lekanya le li-immunity tse ling ho netefatsa sefofane sa ho kenngoa ha 55mmm litene.

5. Sistimi ea boitšoaro bo ikemetseng e etsa hore phala e fepe e fepa le ho itšeha, 'me ho fepa hoa nepahala ebile se potlakile. E ikemetseng haholo, e fokolang ea phoso le ho boloka basebetsi. Sesebelisoa sa ho fepa ka bokhachane se ts'ehetsa 800 * 800mmm Burnch Bunch, boima bo boholo ba ho li kenya ke 25kg ka limithara.

6. Seporo se tukang se emisitsoe ka sistimi e ikemetseng, kahoo e ka netefatsa ts'ebetso e telele e bonolo ntle le ho emisa.

7. E ka fetola mohala oa pele mme e qobelle ho khokhothela ho latela likotlo tse fapaneng, 'me ka bohona mesebetsi ena e sebetsa haholo bakeng sa li-tubense tse ikhethang. Calibration algorithm e tla boela e fapana ho latela li-tubens tse fapaneng.

8. E ka pata likarolo tse ka ho hula moralo ho batch ka fomati ea Excel, e bonolo ebile e boloka nako e ngata ea ho taka.

9. Re tla fapanyetsana likarolo tse ling, tse ling tsa bohlokoa kapa mahlale a bohlokoa ho fihlella mochini oa pope laser ho ntlafatsa Kahoo ho ntlafatsa sena ho atolosa bophelo ba Pipe Laser, ho pholosa lisebelisoa le mosebetsi o tala, ho fokotsa litšenyehelo.

10. Ho tsitsipana le ho kuta le ho kuta lebelo, sehiloeng se sehiloeng se fihla ho limithara tse 90 ka motsotso, 'me sekhahla sa ho khaola se ka fetoha. Ka sethala se phahameng, e pholosa nako e ngata ea mosebetsi. Lisebelisoa li bonolo ho li boloka ho eketsa bophelo ba tšebeletso ea eona.

11. Ho tloha ha ho ts'ehetso ea lefu la tsoekere ho na le matla a matla a botsoi, kahoo phala e ke ke ea sesa ho etsa hore ho nepahala ho sa amoheleheng. 'Me terene e tataisang e sebelisa sesebelisoa sa libricathithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithithica So

12.

13. Mochini o loketse ho cheka thepa e phahameng ea tšepe e tšoanang le koporo, aluminium, e leng li-pimuni tse khanyang le ba bang. E ts'ehetsa potoloho, lisekoere, li-actaular, elliptical, tse tharo, li folete, li boloka nako ea tlhahiso-leseling ea phala.

14. Lisebelisoa li entsoe ka lits'ebeliso tse ngata tsa indasteri ea indasteri le liphihlelo tse ngata tsa ho kenya. Hore na ke lintho tse bonahalang tse imetsoeng kapa tsa ho kuta, boleng bo nepahetseng ba bokhabane bo sebelisetsoang ho kenyelletsa ts'ebeliso e nepahetseng le ho boloka thepa ho isa tekanyong e kholo. Litšila li fokotseha ka tlhaho.

15. Ha ho na lerōle 'me ha ho lerata, e etselitsoe haholo ke khoebo ea tšireletso.

16. E na le mosebetsi oa koloi o ntse o batla ojana, haeba phala e leeme, hlooho e sehiloeng e ka supa le ho tlatsa leeba.

17. Li-pipepes kahare ho lerata le behiloeng li ka fumanoa. Haeba bolelele ba liphaeko ha se loketse, e tla ba alarm.

18. E ka utloisisa mefuta eohle ea moralo o rarahaneng o ke keng oa bonoa ke ho baloa ke sekoti se kang lesoba.

19. Bakeng sa phala e teteaneng e na le mosebetsi oa ho lokisa othamano, e ka eketsang sekhahla sa nakoana ntle le lesoba; ho ntlafatsa ho fokotsa katleho le ho fokotsa nako ea ho fokotsa; Ho fetoloa ha phaetsi e tšesaane le pompo e teteaneng ho ka fumana liparamente tse lumellanang laebraring ea tšebetso.

20. Bakeng sa mochini oa PIPE oa PPER oa PPER laser re na le mefuta e meraro bakeng sa khetho ea hau ea khetho ea hau. P3080 le P30120, ka hona e ka sebetsa bolelele bo bolelele 6000mm.

21. Bophahamo ba pipe ba lokela ho ba ka har'a 320mm kapa diagonal nakong ea 320mm.

22. Mochini o ka khaola ARC, Groove, Oblique.

23. Chuck e fetola matla a kobo ho latela mofuta oa trough, bophara le hlabula le mabone

24. Software ea taolo ea mochini e na le bokhoni ba ho bala ka matla le maballo a bohlale; E ka sebetsa moralo oa 3D ho ea ka tsamaiso ea Kamore ea Tsamaiso ea Cam.

25. Kenya likarolo tsa boleng bo holimo, likarolo tse hlahisitsoeng tse sebelisitsoeng mochini li amohela li-Brands tse tsoang kantle ho naha, ka hona e ka tiisa melao ea mochini.

26. Kenya likarolo tsa boleng bo phahameng, metsoako ea pneumatic

NTS e sebelisitsoeng mochini e amohela li-Brands tse tsoang ka tlung, ka hona e ka netefatsa hore sistimi ea mochini e tsitsitse ebile e kopana le litekanyetso tsa kantle tsa naha.

27.Ba ho se khaola ho etsahala ke ± 0.03mm.

28. Buka e khona ho khaola li-buckle le ts'ebetso ea ts'ebetso.

29. Boleng ba mochini bo phahame. Poupe e ke ke ea fetoloa ke mocheso, 'me lerako le ka hare le se le boreleli kamora ho seha, bokaholimo bo boreleli ntle le ho shrinkage mme ha ho hlokahale hore re shkhanting.

30. Buka e ka khaola 30 °, 40 ° kapa ea 90 ° ho latela moreki a sebelisa 90 ° Ahloe ka ho phethahetseng.