The 7 Phapang ntlha pakeng tsa faeba laser ho itšeha mochine le Plasma ho itšeha mochine.

A re bapiseng le bona mme re khethe mochini o nepahetseng oa ho itšeha oa tšepe ho latela tlhoko ea hau ea tlhahiso. Ka tlase lethathamo le bonolo la phapang e kholo lipakeng tsa fiber laser cutting le Plasma cutting.

| Ntho | PLASMA | FIBER LASER |

| Theko ea thepa | Tlase | Phahameng |

| Sephetho sa ho khaola | Perpendicularity e fosahetseng: fihla ho 10 degreeCutting slot bophara: hoo e ka bang 3mmheavy e khomarelang slagcutting edge roughheat e ama haholo eseng ho nepahala ho lekaneng ho seha moralo o lekantsoeng | Perpendicularity e fosahetseng: ka har'a 1 degreeCutting slot bophara: ka hare ho 0.3mmno e khomarelang slagcutting edge smoothheat e ama smallhigh accuracyno e lekanyelitsoeng holim'a moralo oa ho itšeha. |

| Botenya bo fapaneng | Letlapa le letenya | Letlapa le lesesaane, Letlapa le mahareng |

| Ho sebelisa litšenyehelo | tshebediso ya matla, ama ho lahleheloa ke molomo | ka potlako ho apara karolo, Gas, tshebediso ya matla |

| tshebetso e sebetsang hantle | Tlase | Phahameng |

| Ho khoneha | ho sebetsa ka thata, tšepe e teteaneng, tlhahiso e tlase | ho sebetsa hantle, tšepe e tšesaane le e mahareng, tlhahiso e phahameng |

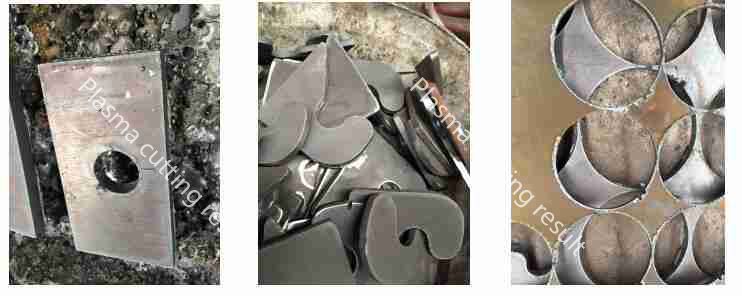

Ho tsoa setšoantšong se kaholimo, u tla fumana TLHOKOMELISO e Tšeletseng ea PLASMA CUTTING:

1, Mocheso oa ho itšeha o ama haholo;

2, tekanyo e fosahetseng ea perpendicular ka ho itšeha, phello ea letsoapo;

3, Hlakola habonolo moeling;

4, paterone e nyane ha e khonehe;

5, eseng ho nepahala;

6, ho itšeha sekotjana bophara;

Tse Tšeletseng MOLEMO OALASER KHOOA:

1, mocheso o monyenyane o ama;

2, tekanyo e ntle ea perpendicular mabapi le ho itšeha,;

3, ha ho na slag e khomarelang, e ntle e tsitsitseng;

4, e sebetsang bakeng sa moralo o nepahetseng oa hige, lesoba le lenyenyane le nepahetse;

5, ho nepahala ka hare ho 0.1mm;

6, ho itšeha sekotjana;

Ha bokhoni ba ho itšeha ka laser ho lisebelisoa tsa tšepe tse teteaneng bo eketseha haholo, bo fokotsang litšenyehelo tsa indasteri ea tšepe.