Kamora ho sebetsa ka thata ka likhoeli tse 'maloa, mohala oa tlhahiso ea mochini oa P2070A o ikatisang oa koporo oa laser bakeng sa ho seha le ho paka li-tube tsa indasteri ea lijo o felile ebile oa sebetsoa.

Ena ke tlhokahalo ea k'hamphani ea lijo ea Jeremane ea lilemo tse 150 ea othomathike ea koporo. Ho ea ka litlhoko tsa bareki, ba hloka ho khaola tube ea koporo e bolelele ba limithara tse 7, 'me mohala oohle oa tlhahiso o lokela ho ba o sa lebelloang le o lumellanang le litekanyetso tsa tšireletso tsa Jeremane. Ho feta moo, phepelo ea koporo ea koporo e lokela ho hloeka 'me ha ho na tube ea litšila,' me ka mor'a ho khaola le ho hloekisa, tube e phethiloeng ea koporo e lokela ho kenngoa ka lebokoseng le khethiloeng ke roboto ka tatellano.

Ka mor'a ho buisana ka makhetlo a 'maloa le ho etsa liteko tsa sampole, qetellong moreki o ile a re fa odara. 'Me re beha pele mochini oa tlhahiso ea mochini oa koporo oa othomathike ka tsela e latelang:

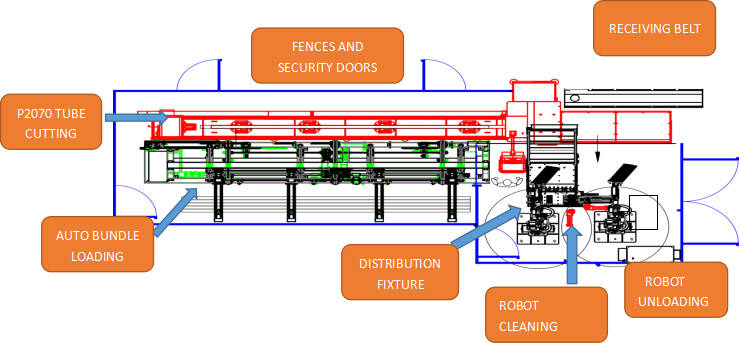

Sebopeho sa line ea tlhahiso

Tlhaloso e qaqileng ea likarolo tsa mochine oa ho itšeha oa koporo o itekanetseng

Tlhaloso e qaqileng ea likarolo tsa mochine oa ho itšeha oa koporo o itekanetseng

(1) 2.5T e pota-potileng koporo ea koporo tsamaiso e potlakileng ea likoloi

Mokhoa oa ho fepa ka potlako, nako ea pele ea ho fepa tube ke 10s, ea ho qetela ke 3s.

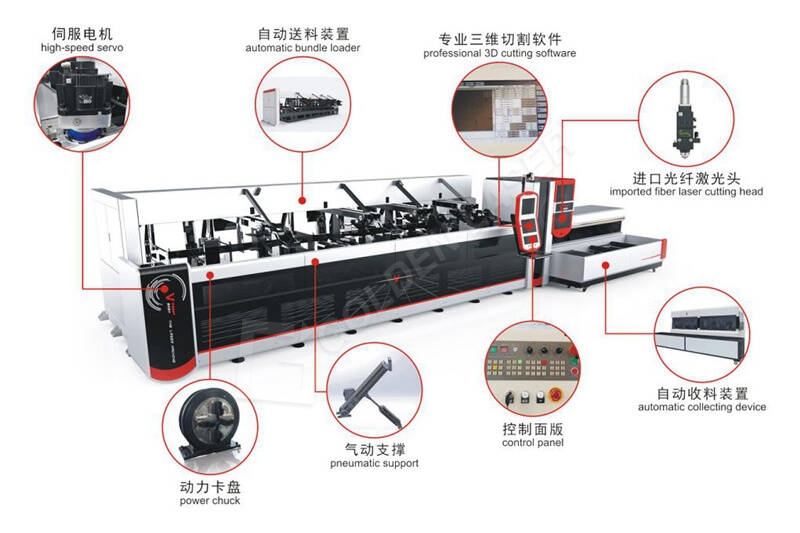

(2)P2070A Koporo e itirisang ka botlalomochine oa ho itšeha oa laser tube

A: E na le ts'ehetso e felletseng ea enjene e phaphametseng e ka netefatsang ho nepahala ho phahameng nakong ea lebelo le phahameng la ho itšeha;

A: E na le ts'ehetso e felletseng ea enjene e phaphametseng e ka netefatsang ho nepahala ho phahameng nakong ea lebelo le phahameng la ho itšeha;

B: ke CNC e laoloang le ho tsamaisoa ke G code e lumellanang le software eohle ea CAM e kang Lantek, Siamanest, Metalix ... joalo-joalo;

C: mochini o fokolitse karolo ea litšila e ka bolokang litšenyehelo tsa hau tsa thepa e tala; (re ka etsa lisebelisoa tse fokolang tsa 50-80mm.);

D: lihlahisoa tse khaotsoeng le tsamaiso ea karohano ea litšila e ka u lumella ho arola lihlahisoa tse felileng le lihlahisoa tse senyehileng habonolo;

E: database e ngata ea meralo ea dijithale e bokelletsoeng ho tsoa ho boiphihlelo ba lilemo tse sebetsang e u thusa ho rala seo u se batlang;

F: Sistimi ea autoload e ile ea hlokomela ho sebetsa ka bo eona ho boloka litšenyehelo tsa basebetsi

(3) Ho amohela Copper tube Belt

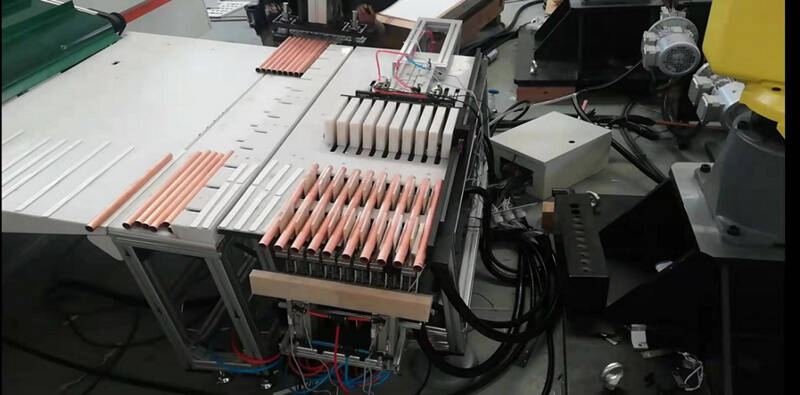

(4) Pneumatic Copper tube Feeding Fixture

(5) Roboto e ikemetseng bakeng sa ho hloekisa pheletso ea li-tube tsa koporo

Fanuc M20iA ka potlako hloekisa le ho phunya lebota le ka hare le khomarelang slag

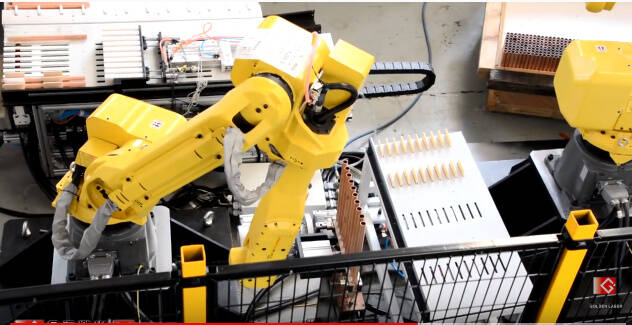

(6) Ho laolla le ho phutha liroboto ka boiketsetso

Kamora ho hloekisa, roboto ea Fanuc M20iA e tšoara ebe e kenya tube e hloekisitsoeng ka lebokoseng la ho paka le ka tlatsoang ka tse ling.

ho feta 3000 li-tubes

(7) Fensetere le mamati a tšireletso

U sebelisa sesebelisoa sa polokeho sa Omron, mochini oohle o lumellana le litekanyetso tsa CE

Ho fihlela litlhoko tsa moreki, re ne re kopantse molaoli oa rona oa porofeshenale oa tlhahiso, moenjiniere oa motlakase, moenjiniere oa othomathike, moenjiniere oa liroboto, le basebetsi ba bang ba nang le boiphihlelo ho etsa mohala ona kaofela oa tlhahiso.

Bakeng sa lintlha tse ling pls sheba sehokelo sa video ho mochini oa ho itšeha oa Golden Laser oa youtube: