Mesebetsi ea tlhahiso ea Laser hajoale e kenyelletsa ho seha, ho cheselletsa, ho phekola mocheso, ho koaheloa, ho beha mouoane, ho ngola mongolo, ho ngola, ho poma, ho koala le ho thatafatsa tšabo. Mekhoa ea tlhahiso ea laser e qothisana lehlokoa le botekgeniki le moruo ka mekhoa e tloaelehileng ea tlhahiso le e sa tloaelehang joalo ka mochini oa mochini le o futhumatsang, ho cheselletsa li-arc, electrochemical, le machining ea ho ntša motlakase (EDM), ho itšeha ka jete ea metsi, ho itšeha plasma le ho itšeha lelakabe.

Ho seha jete ea metsi ke mokhoa o sebelisetsoang ho seha lisebelisoa ho sebelisa jete ea metsi a hatelitsoeng ka boima ba liponto tse 60,000 ka square inch (psi). Hangata, metsi a kopantsoe le abrasive joaloka garnet e etsang hore lisebelisoa tse ngata li khaole ka mokhoa o hloekileng ho thibela ho mamellana, ka ho lekana le ka qetello e ntle. Lijete tsa metsi li khona ho seha lisebelisoa tse ngata tsa indasteri ho kenyelletsa tšepe e sa hloekang, Inconel, titanium, aluminium, tšepe ea lisebelisoa, lirafshoa, granite le poleiti ea lihlomo. Mokhoa ona o hlahisa lerata le leholo.

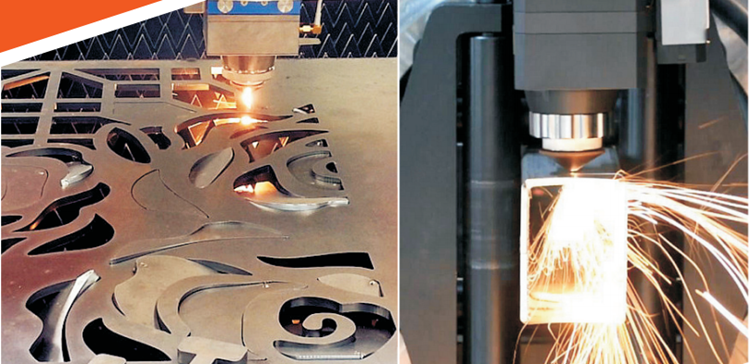

Tafole e latelang e na le papiso ea ho itšeha ka tšepe ho sebelisa mokhoa oa ho itšeha oa CO2 laser le mokhoa oa ho itšeha oa jete oa metsi ho sebetsa thepa ea indasteri.

§ Phapang ea mantlha ea ts'ebetso

§ Lits'ebetso tse tloaelehileng tsa ts'ebetso le ts'ebeliso

§ Matsete a pele le litšenyehelo tse tloaelehileng tsa ts'ebetso

§ Ho nepahala ha ts'ebetso

§ Menahano ea polokeho le tikoloho ea ts'ebetso

Liphapang tsa mantlha tsa ts'ebetso

| Sehlooho | Co2 laser | Ho khaola jete ea metsi |

| Mokhoa oa ho fana ka matla | Leseli 10.6 m (leqhubu le hole la infrared) | Metsi |

| Mohloli oa matla | Laser ea khase | Pompo e phahameng ea khatello |

| Kamoo matla a fetisoang kateng | Beam e tataisoang ke liipone (li-optics tse fofang); phetiso ea fiber ha e joalo e khonahala bakeng sa laser CO2 | Li-hoses tse thata tse nang le khatello e phahameng li fetisa matla |

| Kamoo thepa e sehiloeng e lelekoang ka teng | Jet ea khase, hammoho le khase e eketsehileng e ntša thepa | Jete ea metsi e nang le khatello e phahameng e ntša litšila |

| Sebaka se pakeng tsa nozzle le thepa le mamello e phahameng e lumelletsoeng | Hoo e ka bang 0.2 ″ 0.004 ″, sensor ea sebaka, taolo le Z-axis lia hlokahala | Hoo e ka bang 0.12 ″ 0.04 ″, sensor ea sebaka, taolo le Z-axis lia hlokahala |

| Ho theha mochini oa 'mele | Mohloli oa laser o lula o le ka har'a mochini | Sebaka sa ho sebetsa le pompo se ka behoa ka thoko |

| Lethathamo la boholo ba tafole | 8′ x 4′ ho isa ho 20′ x 6.5′ | 8′ x 4′ ho isa ho 13′ x 6.5′ |

| Tlhahiso e tloaelehileng ea beam ho workpiece | Ho tloha ho 1500 ho isa ho 2600 Watts | 4 ho 17 kilowatts (4000 bar) |

Mekhoa e tloaelehileng ea lisebelisoa le lisebelisoa

| Sehlooho | Co2 laser | Ho khaola jete ea metsi |

| Lisebelisoa tse tloaelehileng tsa ts'ebetso | Ho seha, ho cheka, ho betla, ho tlosa, ho hlophisa, ho cheselletsa | Seha, ablation, structuring |

| 3D ho itšeha lintho tse bonahalang | E thata ka lebaka la tataiso e thata ea maballo le taolo ea sebaka | Hoa khoneha ho tloha ha matla a setseng ka morao ho workpiece a senyehile |

| Lisebelisoa tse khonang ho khaoloa ke mokhoa | Litšepe tsohle (ntle le litšepe tse khanyang haholo), lipolasetiki kaofela, likhalase le lehong li ka sehoa | Lisebelisoa tsohle li ka khaoloa ka mokhoa ona |

| Metsoako ea lintho tse bonahalang | Lisebelisoa tse nang le lintlha tse fapaneng tse qhibilihang li ke ke tsa khaoloa | Hoa khoneha, empa ho na le kotsi ea delamination |

| Mehaho ea sandwich e nang le likoti | Sena ha se khonehe ka laser CO2 | Bokhoni bo fokolang |

| Lisebelisoa tsa ho seha tse nang le phihlello e fokolang kapa e senyehileng | Ho khoneha ka seoelo ka lebaka la sebaka se senyenyane le hlooho e kholo ea laser | E fokotsehile ka lebaka la sebaka se senyenyane pakeng tsa nozzle le thepa |

| Thepa ea thepa e sehiloeng e susumetsang ts'ebetso | Litšobotsi tsa ho monya ha thepa ho 10.6m | Ho thatafala ha lintho tse bonahalang ke ntlha ea bohlokoa |

| Botenya ba thepa eo ho sehang kapa ho sebetsa ho eona ho nang le chelete e ngata | ~0.12″ ho isa ho 0.4″ ho latela thepa | ~0.4″ ho isa ho 2.0″ |

| Likopo tse tloaelehileng tsa ts'ebetso ena | Ho itšeha ka tšepe ea lakane e sephara ea botenya ba mahareng bakeng sa ts'ebetso ea tšepe ea lakane | Ho seha majoe, lirafshoa le litšepe tsa botenya bo boholo |

Matsete a pele le litšenyehelo tse tloaelehileng tsa ts'ebetso

| Sehlooho | Co2 laser | Ho khaola jete ea metsi |

| Ho hlokahala chelete ea pele ea chelete | $300,000 ka pompo ea 20 kW, le tafole ea 6.5'x 4' | $300,000+ |

| Likarolo tse tla tsofala | Khalase e sireletsang, khase li-nozzles, hammoho le lerōle le li-filters tsa likaroloana | Nozzle ea jete ea metsi, nozzle e tsepamisitseng maikutlo, le likarolo tsohle tsa khatello e phahameng joalo ka li-valve, li-hose le litiiso. |

| Karolelano ea tšebeliso ea matla ea sistimi e felletseng ea ho itšeha | Nka 1500 Watt CO2laser: Tšebeliso ea matla a motlakase: 24-40 kW Khase ea laser (CO2, N2, He): 2-16 l/h Khase e khaohang (O2, N2): 500-2000 l/h | Nka pompo ea 20 kW: Tšebeliso ea matla a motlakase: 22-35 kW Metsi: 10 l/h Abrasive: 36 kg/h Ho lahla litšila |

Ho nepahala ha ts'ebetso

| Sehlooho | Co2 laser | Ho khaola jete ea metsi |

| Bonyane boholo ba sekoahelo se sehang | 0.006 ″, ho latela lebelo la ho itšeha | 0.02" |

| Khaola ponahalo ea bokaholimo | Sebaka se sehiloeng se tla bontša sebopeho se striated | Sebaka se sehiloeng se tla bonahala se phatlohile ka lehlabathe, ho itšetlehile ka lebelo la ho itšeha |

| Boemo ba likhahla tse sehiloeng ho bapisa ka ho feletseng | E ntle; ka linako tse ling e tla bontša mahlakore a conical | E ntle; ho na le phello ea "mohatla" ka li-curve tabeng ea lisebelisoa tse teteaneng |

| Ho mamella ho sebetsa | Hoo e ka bang 0.002 ″ | Hoo e ka bang 0.008″ |

| Boemo ba ho chesoa ha sehiloeng | Ho chesoa ha karolo e itseng feela ho etsahala | Ha ho cheso e etsahalang |

| Khatello ea mocheso ea lintho tse bonahalang | Deformation, tempering le liphetoho tsa sebopeho li ka 'na tsa etsahala linthong tse bonahalang | Ha ho khatello ea mocheso e hlahang |

| Matla a sebetsang linthong tse lebisang ho khase kapa jete ea metsi nakong ea ts'ebetso | Khatello ea khase e baka mathata a masesaane workpieces, sebaka ha e kgone ho baballa | Holimo: likarolo tse nyane, tse nyane li ka sebetsoa feela ka tekanyo e lekanyelitsoeng |

Lintlha tsa polokeho le tikoloho ea ts'ebetso

| Sehlooho | Co2 laser | Ho khaola jete ea metsi |

| Tšireletseho ea botholitlhoko tsa thepa | Likhalase tsa tšireletso tsa laser ha li hlokehe ho hang | Ho hlokahala likhalase tsa tšireletso, tšireletso ea tsebe, le tšireletso khahlanong le ho kopana le jete ea metsi a khatello e phahameng |

| Tlhahiso ea mosi le lerole nakong ea ts'ebetso | E etsahala; lipolasetiki le metsoako e meng ea tšepe li ka hlahisa likhase tse chefo | Ha e sebetse bakeng sa ho khaola jete ea metsi |

| Tšilafalo ea lerata le kotsi | Tlase haholo | E phahame ka tsela e sa tloaelehang |

| Litlhoko tsa ho hloekisa mochini ka lebaka la bohlasoa ba ts'ebetso | Hloekisa tlaase | Hloekisa holimo |

| Ho khaola litšila tse hlahisoang ke mokhoa | Ho seha litšila haholo-holo ka mokhoa oa lerōle le hlokang ho ntšoa ha vacuum le ho sefa | Lintho tse ngata tse sehang litšila li etsahala ka lebaka la ho kopanya metsi le li-abrasives |