Oval Tube | Laser Cutting Tharollo - Theknoloji e Feletseng ea Oval Tube Steel Processing

Oval Tube ke eng le Mofuta oa Oval Tubes?

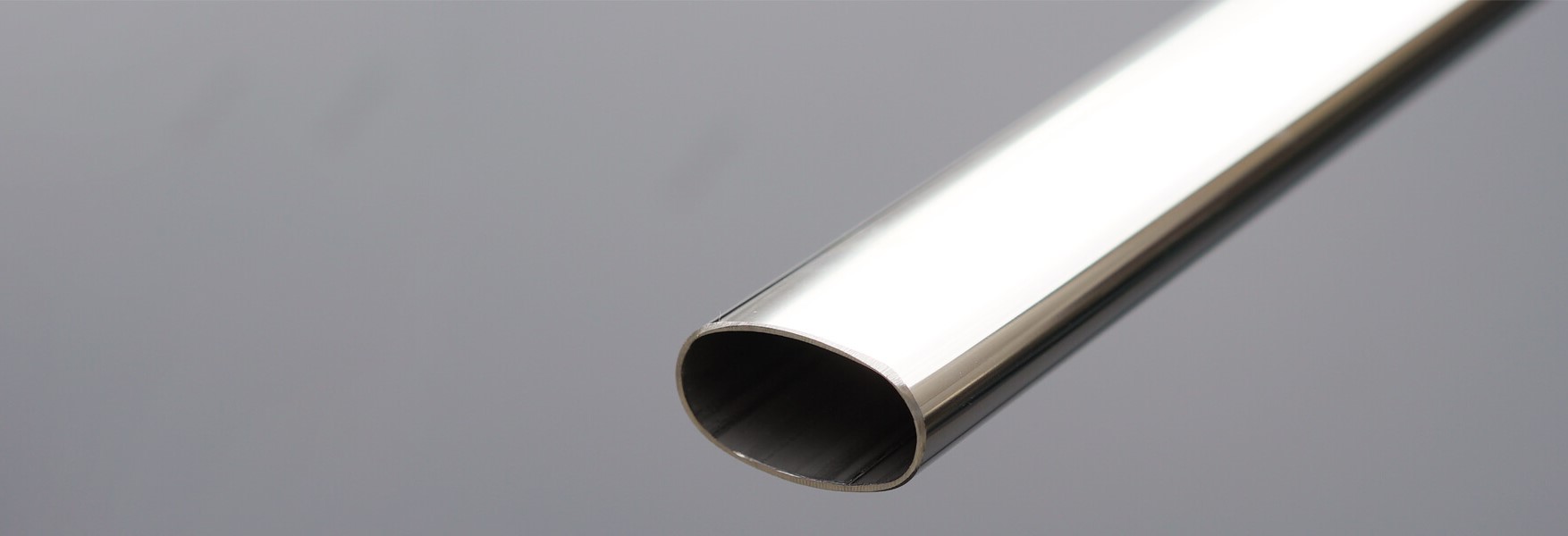

Oval Tube ke mofuta oa li-tubes tsa tšepe tse nang le sebopeho se ikhethileng, ho latela ts'ebeliso e fapaneng, e na le liphaephe tse fapaneng tsa oval ea sebopeho, joalo ka liphaephe tsa tšepe tse elliptical, lipeipi tsa tšepe tse se nang moeli, lipeipi tsa tšepe tse sephara, lipeipi tsa tšepe tsa galvanized, lipeipi tsa tšepe tse tapered, liphaephe tsa tšepe tse sephara, liphaephe tse tloaelehileng tsa tšepe ea elliptic le lisebelisoa tse fapaneng tsa tšepe. Li-tubes tsa tšepe tse nepahetseng tsa boholo bofe kapa bofe ka botenya ba 1mm-30mm.

Ho tsoa ho Lisebelisoa, ho kenyelletsa aluminium oval tube, tšepe ea oval tube, tšepe e sa hloekang ea oval tube joalo-joalo.

Tšebeliso ea Oval Tube?

Oval Tube e sebelisoa haholo indastering ea likoloi bakeng saho felloa ke li-tube tsa oval, mokhabiso, lisebelisoa tsa lipalangoang, kaho ea boema-fofane, tšehetso ea borokho, karache ea mahlakore a mararo, papatso ea ka ntle, lisebelisoa tsa ho ikoetlisa, lisebelisoa tsa litlolo tse kang DOT guardrails, lisebelisoa tsa matla a moea, tlhahiso ea likoloi, le liindasteri tse ling.

Molemo oa Oval Tube ke ofe?

1. Ho tloha karolong e ka ntle ea bokaholimo, likarolo tse peli tsa galvanizing tse chesang le lipente tsa spray li sebelisoa ho thibela kutu. Sebaka se ka hare sa bokaholimo se entsoe ka liphaephe tsa tšepe tse se nang moeli tse nang le likhopo tse ka hare tse hlahelletseng le liphaephe tsa polasetiki tsa polypropylene ka theknoloji e ikhethang ea ho sebetsa.

2. The elliptical tube e thata ebile e na le tekanyo e itseng ea bonolo. Ha ho bonolo ho holofala ke extrusion mme e hanana le tšusumetso. Tšepahala ea ho kenya e phahame, 'me ha ho na embrittlement tlas'a khase le khanya ea letsatsi.

3. Ho hanyetsa boemo ba leholimo le ho hanyetsa khatello. Mocheso o sebetsang oa pipe e futhumatsang: 0 ° C~75 ° C, mocheso o fihla ho 95 ° C ka motsotsoana, khatello≤1.5MPa; mocheso o sebetsang oa pipe ea metsi a pholileng: 0°C~55C, khatello≤2.0MPa.

4. Tšireletso e matla ea mocheso le ho hanyetsa ho bola. E loketse ho patoa lefifing empa hape e ka kenngoa lefifing.

5. Hloekisa lintho tse se nang chefo, tse phetseng hantle, 'me li bolokehile. Mekhahlelo e fapaneng ea ts'ebetso e fihletse litlhoko tsa maemo a boleng a Lekala la Bophelo.

6. Sekoti se ka hare se boreleli ebile se hloekile, ha se mafome, ha se bokelle, 'me tekanyo ea phallo eohle ke 25% -30% e kholoanyane ho feta hose ea tšepe e nang le bophara bo tšoanang ba lebitso. Ha ho na tšenyo ea bophara ba pipe ho kopanngoa.

7. Theknoloji e ikhethang ea ho sebetsa e khethiloe. Sebopeho sa sebopeho sa convex se kang sa letlooa se hlahisoa le ho sebetsoa ka har'a lekhalo le ka hare la phala ea tšepe e sa tsitsang, e leng se eketsang haholo khohlano e thellang lipakeng tsa hose ea tšepe ea bokaholimo le hose ea polasetiki e kahare.

Ka lehlakoreng le leng, ho se tsitse ha deformation ea mocheso pakeng tsa liphaephe tse ka hare le tsa ka ntle ho fokotsehile ka mokhoa o utloahalang. Mocheso oa katoloso ea phala ea elliptical pipe ke 2.5×(1/100000)/°C,' me bophelo ba ts'ebeletso bo feta makhetlo a 5 ho feta peipi ea tšepe e nang le metsi a chesang.

8. Ho kenya ho bonolo ebile ho ka tšeptjoa. The tube e kopantsoe ke li-connectors tsa lebota tse lokolloang ka potlako, tse sa hlokeng ho roala, ho boloka nako le boiteko.

The Large-diameter square tube e na le sebaka sa kopo se tloaelehileng haholo, hobane botenya ba lerako la eona bo teteaneng haholo, kahoo bo ka mamella khatello e ngata ea ho sebetsa. Ka kakaretso, e ka sebelisoa e le lisebelisoa tse tala tsa likarolo tse se nang letho, tse sebelisetsoang ho kenya matla le lits'ebetso tsa bohlokoa tsa lipeipi.

Ebile, e ka sebelisoa e le li-tubes tsa meralo ea lifofane, lipeipi tsa tlhahlobo ea oli e sa tsoakoang, le lipeipi tsa lisebelisoa tsa petrochemical. Ha ho sebelisoa lipeipi tsa tšepe tse lisekoere, li tlameha hape ho latela maano le melaoana e amehang. Ka hona, litšebeliso tse fapaneng tsa mantlha li hloka ts'ebeliso ea lipehelo le mefuta e fapaneng ea liphaephe. Sena se boetse se bontša ntho e hlokahalang bakeng sa ho sebelisoa ha liphaephe tsa elliptical, haholo-holo Ha u tsamaisa lintho tse kotsi le tse tukang, ho hlokahala hore u fumane liphaephe tsa tšepe tse se nang moeli tsa litlhaloso tse loketseng le mehlala, e le hore likotsi tsa tšireletso li ka qojoa ka mokhoa o utloahalang.

Mokhoa oa ho hlahisa li-oval tubes?

Senotlolo sa mela ea ts'ebetso ea tlhahiso mofuteng oa sehlahisoa. Ho tloha lihlahisoa tse tala ho ea lihlahisoa tse felileng, letoto la mekhoa ea theknoloji le tlameha ho fetisoa. Ts'ebetso eohle ea theknoloji ena ea ts'ebetso e tlameha ho etsoa ka lisebelisoa tse fapaneng tsa indasteri, welding ea motlakase, lisebelisoa tsa taolo ea motlakase le lisebelisoa tsa tlhahlobo. Mefuta e fapaneng ea mechini le lisebelisoa li na le mefuta e fapaneng ea maemo a sebetsang ho latela melaoana e fapaneng ea ts'ebetso ea tlhahiso.

1. Mehato e tloahelehileng ea li-tube tse nang le maqhubu a phahameng: ho phunya-hot-rolled strip flattening-end and end cutting-hot-rolled strip butt welding-looper discharge -Forming-Electric welding-Removal of burrs-Die-Flaw discover-Fly cutting-Initial inspection-Seamless-processing pipeen-Pressing pipeen ho lemoha-Kopitsa le barbotage-E felile lihlahisoa.

2. Seamlessly spliced elliptical steel tube e boetse e bitsoa elliptical steel pipe, e leng mokhoa oa tlhahiso ea phala e se nang seamless.

3. Mokhoa oa ho kobeha oa tšepe e sa hloekang elliptical tube ka kakaretso o amohela mokhoa oa molao oa cam. Sephetho sa hore na ke makhetlo a makae mokhoa oa molao-motheo oa cam o sebelisoang ho sebetsana le li-tubes tse tšesaane tse entsoeng ka tšepe tse sa hloekang tse nang le li-arcs tse ngata ke phello ea linetefatso tse ngata. E mong le e mong o utloile ka cam. Camshaft e potoloha, molateli o hokahane le cam contour, 'me molateli o etsa motsamao o tšoanang.

Ho ea ka molao-motheo ona: ha feela li-arcs tse 5 li entsoe ka hlobo, 'me bolelele ba karolo e bohareng ea arc e' ngoe le e 'ngoe e lekana le bolelele ba karolo e bohareng ea sehlahisoa sa sehlahisoa (hobane R e holim'a hlobo e nang le rebound e kholo e nyane ho feta R sehlahisoa), hlobo ke setsi sa arc se nang le angle e kholo e kenyelelitsoeng e le setsi sa ho potoloha. Karolo e tsamaisoang e sebelisa cylinder. Ka lebaka la ho hatelloa ha khase le valve ea khatello ea khatello e ka sebelisoa ho fetola khatello, haeba khatello ea ho khumama e le khōlō, u ka sebelisa cylinder ea matla a mabeli. , Molamu oa silinda o hokahane le setulo se kobehileng, 'me ho na le seporo sa tataiso tlas'a setulo sa rolara. Lintlha tse ka sehloohong tse amang ho sosobana ha tube ea oval ke lebelo la ho kobeha le lisebelisoa tsa lesela la oval tube.

Joang ho laola lebelo la ho kobeha? The proportional flow valve e ka sebelisoa ho laola lebelo la pele le ka morao la silinda e kholo. Ha ho kobeha radius ea ntho e nyane, taolo ea lebelo e lokela ho ba e loketseng.

Mokhoa oa ho khaola li-oval tubes hore e be lihlahisoa tse batloang ke Yur?

Ho ea ka litlhoko tse fapaneng tsa ho itšeha, u ka sebelisa mokhoa oa ho itšeha ka letsoho kapa mokhoa oa ho itšeha. 'Me ho sebelisa mekhoa e fapaneng ea ho itšeha, litšenyehelo li tla fapana haholo. Joalo ka mochini oa lisakha o tla khaola tšupu empa o sa khone ho phunya phaephe, mochini o sehang le sesebelisoa se senyane sa ho seha li-tube tse nyane.

Haeba u batla ho feta bokgoni bo phahameng 'me ha ho na moeli itšeha moralo seha mochine, ka nako eo afiber laser tube ho itšeha mochinie tla ba khetho ea hau e ntle.

Hobaneng ha Mochini oa ho Seha Laser oa Tube e le Khetho ea Hao e Molemohali ea ho Sebelisa Oval Tube?

Metal Laser Cutting ke mokhoa o sa thekeseleng oa mocheso o phahameng le mokhoa oa ho itšeha ka lebelo le phahameng, ha ho na tšitiso nakong ea ho itšeha, ho nepahala ho fihla ho 0.1mm, ho ka khaola sebopeho leha e le sefe holim'a oval tube ea hau. Sephetho se phethahetseng sa ho itšeha ka laser ho aluminium oval tube, tšepe ea oval tube, tšepe e sa hloekang ea oval tube joalo-joalo.

Golden Laser ke e 'ngoe ea baetsi ba mochini oa ho itšeha oa laser oa China, ka ho le letona e fana ka tharollo e felletseng ea laser bakeng sa ts'ebetso ea Oval Tubes. Ka tlase ke tlhahlobo ea bareki ba rona ba sebelisang mochini oa ho itšeha oa laser bakeng sa ho seha li-oval tubes, mohlomong le uena u na le tlhoko e tšoanang ea oval tube exhaust cutting joalo ka eena.

Tlhokahalo ea Customer Oval Tube Cutting:

89*38 le 114*64mm oval tubes, Bolelele ho tloha 4.5m—6m. Ho khaola libopeho tse fapaneng le tlhoko ea "0" Tailer.

U ka kopana joang le tlhoko ea ho itlhophisa ea Moreki mabapi le tlhokahalo e khethehileng ea sebopeho sa carbon ovel tube cutting?

1. Bakeng sa ho kenya li-tubes tsa tšepe ka mokhoa o itekanetseng, o ka sebelisa mochine oa ho fepa li-tube, o na le taolo e nepahetseng ea servo ho netefatsa khetho e nepahetseng ea li-tubes, ebe o fepa tube-pushing tube-lekanya bolelele ba tube. Bohle ba etsa bonnete ba hore phala e romelloa mochine oa ho itšeha oa laser ka mokhoa o tsitsitseng le o nepahetseng

2. Lintlha tsa tsamaiso ea tsamaiso ea PA CNC le tsamaiso ea li-auto feeder li arolelanoa, e leng se tiisang ho nepahala ha Clamping boemo-pele ho itšeha boemo-Boemo bo lahlehileng bo fanoa ka nepo. Ts'ebetso eohle e bonolo.

3. Mehlahare e ka pele le e ka morao e entsoeng ka mokhoa o ikhethileng e netefatsa hore laser e itšeha ka nepo ea phala ea tšepe ea oval.

4. Hobane bolelele ba phala bo batla bo le boholo, clamp ea feeder le tšehetso ea thepa e tla kena-kenana, kahoo mosebetsi oa rona oa ho arolelana data o ka rarolla bothata bona hantle. Re tla ikhethela mokhoa oa ho ntša phala ho latela libopeho tse fapaneng tsa pipe.

5. Lenaneo la ho itšeha ka laser le fetoha ka tsela e iketsang ntle le ho kenella ha motho.

Mokhoa oa ho Rarolla Bothata ba Pipe le Li-claw tse entsoeng ka tloaelo tse ka 'nang tsa etsahala nakong ea ho itšeha ka Laser?

Ka mor'a liteko tse ngata, radian e khethehileng ea ho qetela, le ho sebetsa. E rarollotse bothata ba mongoapo

Joang ho etsa bonnete ba hore Tube Laser Cutting Nepahetse?

Kaha ts'ebetso ea tlhahiso ea phala ea seam ea mahlo e fapane le ea pipe e tloaelehileng, ho thata haholoanyane ho finyella ho otloloha ho tloaelehileng le ho phunyeha ha phala.

Lisebelisoa tse khethehileng le boqapi bo ikhethang, tlhahlobo e tsoelang pele ea liphaephe tse 100, ho nepahala le khotsofalo ea bareki!

Mokhoa oa ho Finyella Lithako tsa Zero

Ho ea ka litšoaneleho tsa litšoantšo tsa bareki, li-tailings tse 0 li tiisitsoe ka hare ho halofo ea mithara, ts'ebetso ea ho bula karete, litlhophiso tsa Lantek's (Professiona Tube Nesting Software), matla a feto-fetohang a chuck, joalo-joalo, qetellong a finyella 0 tailings.

Video ea OvalMochini oa ho itšeha oa Laser oa TubeAutomatic Cutting Tharollo Bakeng sa Reference Hao.

Haeba u thahasella kapa u na le tlhokahalo e tšoanang ea mochini oa oval tube laser cutting, pls ikutloe u lokolohile ho ikopanya le rona.