Romella Lipatlisiso bakeng sa Tlhahisoleseling e Ncha ka ho Fetisisa ea Mochini oa ho Seha Laser oa Robot le Theko!

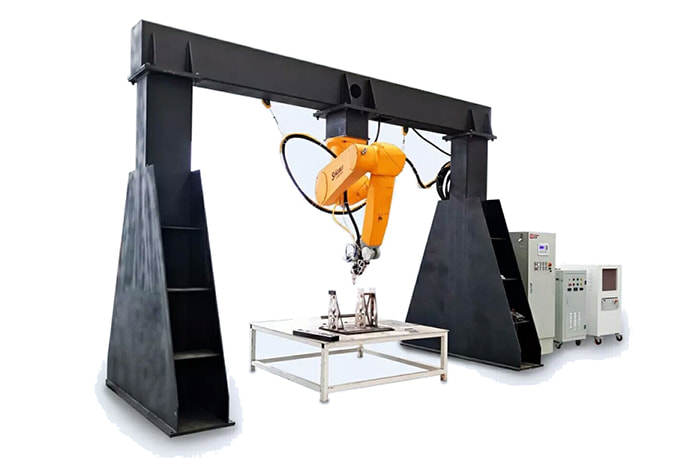

Mochini oa ho itšeha oa 3D laser

- Fiber Laser Cutter e nang le Robotic Arm System.

Lintlha-khōlō tsa Mochini oa ho Seha oa Robot 3D Laser

1. XR160L bakeng sa k'hamphani ea ka e behang liroboto tse khethehileng tsa indasteri ea mochini oa mochini oa mochini, lisebelisoa tsa liroboto tsa Stäubli RX160L, IPG500W fiber laser, LASERMECH hlooho ea laser (ho kenyeletsoa mochini o tsamaeang), tafole ea maemo, chiller, polokeho le likarolo tse ling tsa mantlha.

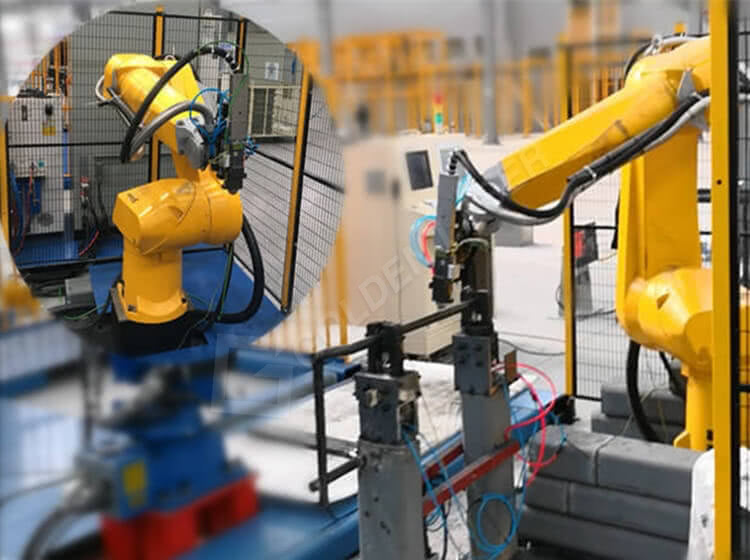

2. Khokahano ea li-axis tse 6, mefuta e mengata ea mosebetsi, ho fihlela sebaka se selelele, matla a ho jara, e ka ba sebakeng sa mosebetsi bakeng sa ho seha pina ea 3D.

3. Letsoho le tšesaane, le lesesaane, leha maemo a le boima, lithibelo libakeng tse ngata, li ntse li ka fihlela ts'ebetso e phahameng ea ts'ebetso.

4. Lebelo la ts'ebetso le boemo bo ka fetoloa, ho finyella ho nepahala ha tlhahiso e ntle ka ho fetisisa, chai e ngata, le lebelo le phahameng.

5. Lerata le tlaase, nako e tloaelehileng ea ho lokisoa ke nako e telele, bophelo bo bolelele ba tšebeletso

6. Manipulator e ka qhekelloa ka terminal e tšoaroang ka letsoho

7. Ka ho fetola lenaneo le liphetoho tsa hardware, li ka finyella ho itšeha ka laser, welding laser, ho paka, ho tšoara le mesebetsi e meng.

3D Laser Cutting Machine Features

1.Mohloli oa Laser: tšebeliso ea lisebelisoa tse phahameng tsa IPG fiber lasers, ts'ebetso e phahameng, litšenyehelo tse tlaase tsa tšebeliso e kopanetsoeng.

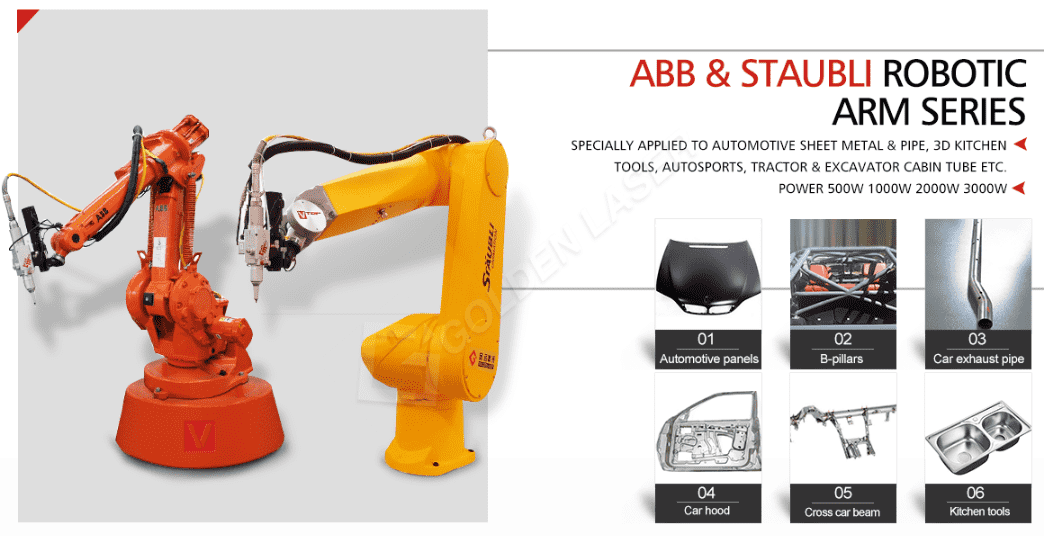

2.Ho kengoa ts'ebetsong ha laser cutting ea mekhatlo ea ts'ebetsong bakeng sa robot ea Swiss Staubli. Staubli roboto ke roboto e nepahetseng ka ho fetisisa indastering ea liroboto. Tšebeliso ea 'mele oa liroboto tsa aluminium titanium alloy, moralo oa ho fokotsa li-harmonic,' mele oa liroboto o amanang le mefuta e meng, e bobebe, lebelo le phahameng, ho nepahala ho phahameng. Liroboto tsa indasteri tsa TL160L ka har'a sekhahla se senyenyane sa sehiloeng se setle le sebopeho se seholo ho bolella sehiloeng sa laser se amanang le lihlahisoa tse ling se na le melemo e hlakileng. Ka ho itšeha ka lebelo le phahameng la laser, sistimi ea liroboto ea Staubli e ka fihlela lebelo la 18 m / min ntle le jitter, lihlahisoa tse ling ha li fane ka tiiso ea lebelo la ho itšeha la 10 m / min ho netefatsa liphetho tse ntle tsa ho itšeha. Hape ka sehiloeng se senyenyane se pota-potileng, o ka khaola bophara bo bonyenyane ka ho fetisisa ba 2mm e pota-potileng, seha se setle le se setle, seo mefuta e meng ea liroboto tsa indasteri e ke keng ea e etsa.

Robot ea 3.Staubli e ka lokisoa ho ea ka litlhoko tsa sebele tsa bareki ba software ea off-line programming, software e ka bala software ea 'mapa ea mahlakoreng a mararo hohle vda, igs, x_t, sldprt, prt, par le mekhoa e meng, ka ho toba ho software compiler track process, Ho ruta, ho bonolo le ho atleha ho finyella sehlahisoa sa mofuta oa mosebetsi oa lenaneo.

4.Latela hlooho ea ho itšeha ea laser: ho ikhethela le lihlahisoa tse holimo tsa machaba tsa hlooho ea ho itšeha ka laser ho etsa bonnete ba hore sefate sa laser se lula se le sebakeng sa ho tsepamisa maikutlo ho netefatsa phello ea ho itšeha.

5.Sistimi e thusang ea ho foka moea: sistimi e kopanya moea o phahameng oa khatello, naetrojene, oksijene sebopeho sa mohloli oa khase e meraro le tsela ea khase e phahameng le e tlase, moreki a ka khetha ho latela litlhoko tsa boleng ba ts'ebetso le litšenyehelo tsa khase e thusang.

Sistimi ea 6.Lubrication: Mochini oa ho itšeha oa 3d oa laser o na le mokhoa oa ho tlotsa oa letsoho, o fokotsa ho roala ha likarolo tse tsamaeang, ho netefatsa lebelo le phahameng la mochini oohle oa liroboto tsa laser.

Video ea Robot Fiber Laser Cutting Machine e sebetsang

Robotic Arm 3D Laser Cutting Machine Sebakeng sa Bareki

Robotic Arm 3D Laser Cutting Metal Tubes le Metal Sheets Sample

U batla ho tseba haholoanyane ka Robot Laser Cutter?

Sesebelisoa sa Material & Indasteri

E sebetsa ho mefuta eohle ea phala ea tšepe e sa lekaneng le lakane ea tšepe ea laser, e loketseng indasteri ea likoloi, tlhahiso ea hlobo, lisebelisoa tsa kichineng, lihlahisoa tsa tšepe, tse kang ho itšeha ka mokhoa o itekanetseng.

1. Bakeng sa likoahelo tsa letlapa la likoloi le likarolo tsa chassis le lihlopha tse ling tsa lihlahisoa tse nyenyane, tse kang 'maraka oa tlhokomelo, literaka, libese, mechine ea kaho, likoloi tse fetotsoeng joalo-joalo.

2. Ka tlhahiso e feto-fetohang ea mochine oa ho itšeha oa laser, ho e-na le setempe se bulehileng, se loketseng tlhahiso ea motho ka mong, empa hape se khutsufatsa potoloho ea lihlahisoa tsa lihlahisoa, karabelo e potlakileng 'marakeng.

3. Ka mokhoa oa ho itšeha oa laser oa robot, ho e-na le ho itšeha ka letsoho ho plasma, ho nolofatsa mokhoa ona haholo, empa hape o 'nile a hlaseloa ke basebetsi ba plasma ba moetsi tsamaisong ea bothata.

4. Kakaretso ea theko e tlase ea lisebelisoa, tšebeliso ea theko e tlase, ts'ebetso e phahameng, thepa e 'ngoe e tsoang kantle ho mochini oa ho itšeha oa laser ea 5-axis, chelete e ngata ea ho boloka litšenyehelo tsa mosebetsi o mong le o mong.

5. E loketse bakeng sa fektheri e amohelang ts'ehetso ea phepelo e nyane ea pele ea batch, le lihlahisoa tse ling ho eketsa bokhoni ba tlhahiso ka mor'a setempe sa hlobo, nts'etsopele ea hlobo ho fokotsa kotsi ea matsete.

Mechini ea Teknoloji Parameters

ABB2400 Robotic Arm Main Technical parameters

| Palo ea lilepe tsa roboto | 6 | Mojaro oa axis oa botšelela | 20Kg |

| Crane ea robotiki | 1.45m | Boemo bo phetoang | 0.05 limilimithara |

| Boima ba 'mele | 380Kg | Palo ea li-volts | 200-600V, 50/60Hz |

| Tšebeliso ea matla | 0.58kw | matla a lekantsoeng | 4KVA/7.8KV |

| ABB 2400 Robot gantry mochini oa ho itšeha mekhoa ea tekheniki | |||

| Likarolo tse akaretsang tsa lisebelisoa | |||

| Sebaka sa fatše(mxm) | hoo e ka bang 3 * 4.2 (ho kenyeletsoa li-chillers le tsamaiso e phahameng ea ho omisa moea) | ||

| Bophahamo bo sebetsang | 350 limilimithara | Lerata | <65 Db(ho sa kenyelelitsoe fene ea ho tima) |

| Litlhoko tsa phepelo ea motlakase | AC220V±5% 50HZ (Simplex) | Kakaretso ea matla | 4.5KW (ntle le moea) |

| Litlhoko tsa tikoloho | Mefuta e fapaneng ea mocheso: 10-35 ℃ Mongobo o fapaneng: 40-85% 1000 limithara ka tlase ho bophahamo ba leoatle, ts'ebeliso ea tikoloho ntle le ho cha, ho phatloha, matla a khoheli, tšisinyeho ea lefatše e matla. | ||

| Lintlha tse ka sehloohong tsa mohloli oa laser | |||

| Mofuta oa laser | Fiber laser | ||

| Lisebelisoa tsa laser | Tsoela pele/ Ketso ya ho fetofetoha | Matla a laser | 700W (1000w 2000w 3000w kgetho) |

| Spot mode | Mekhoa e mengata | Laser wavelength | 1070nm |

| Sistimi e thusang | |||

| Sistimi ea ho pholisa | Pompo ea lipompo tse peli tse nang le mocheso o le mong e nang le mochini oa tlhoekiso ea chiller (tekanyo e ikhethileng) | ||

| Sistimi ea ho futhumatsa mohloli oa laser | 350W moea o otlolohileng oa moea (sebopeho se ikhethileng) | ||

| Sistimi e thusang ea khase | Mehloli e meraro ea khase e nang le khatello e habeli (tekanyo e ikhethileng) | ||

| Hlooho ea ho itšeha ka laser | Talo-morao e matla | ||

Lihlahisoa tse amanang

-

RN16 / RN18 / RN26 (ABB X2400D/X2400L / Staubli XR160L)

Multifunction 3D Robot Laser Cutting Machine Bakeng sa Metal Sheet le Metal Tube Cut -

VR16 / VR18 / VR24

Fiber Laser Robot Arm 3D Cutting Tube le Pipe Bakeng sa likarolo tsa Auto -

RE16/RE18/RE26

Roboto Laser Seha Mochini Cell