1. Kodi pepala ndi chiani?

Silicon steel ma sheent omwe amagwiritsidwa ntchito ndi magetsi omwe amagwiritsidwa ntchito nthawi zambiri amakhala ngati ma sheet a silika. Ndi mtundu wa Ferrokilicon yofewa ya magnetic yomwe imaphatikizapo mpweya wotsika kwambiri. Nthawi zambiri zimakhala ndi 0,5-5% silicon ndipo imagundidwa ndi kutentha ndi kuzizira. Nthawi zambiri, makulidwe ndi osakwana 1 mm, motero amatchedwa mbale yopyapyala. Kuphatikiza kwa Silicon kumawonjezera chisudzo cha ma heroctication ndi maginito okwanira, kuchepetsa kulumikizana, kutaya kochepa (kutaya chitsulo) komanso kukalamba kwamatsenga.

Chinsalu cha silicon chimagwiritsidwa ntchito popanga ma cores achitsulo kwa osiyanasiyana omasulira, mota ndi majedzora.

Mapepala amtunduwu a slicon steel ali ndi katundu wabwino kwambiri wamagetsi, ndi zinthu zofunika kwambiri komanso zofunikira pamavuto mu mphamvu, zolumikizana ndi mafakitale.

2. Makhalidwe a Sicnon pepala

A. Kutayika kochepa kwachitsulo ndiye chisonyezo chofunikira kwambiri. Mayiko onse padziko lapansi amatiyika chitsulo ngati kalasiyo, kutsitsidwa kwachitsulo, kalasi yapamwamba, komanso yabwinoko.

B. Maginito apamwamba. Pansi pa gulu lomwelo lamagetsi, pepala la silicon limapeza maginito apamwamba kwambiri. Voliyumu ndi kulemera kwa magalimoto ndi chosinthira cha chitsulo chomwe chimapangidwa ndi pepala lomwe limapangidwa ndi silicon ndi laling'ono komanso lowala, motero limatha kupulumutsa mkuwa, zowonjezera.

C.HiGher Carding. Ndi mawonekedwe osalala, makulidwe ndi mayunifolomu ndi makulidwe, pepala lachitsulo la silika limatha kukhala lalitali kwambiri.

D. Pansi ili ndi zomatira bwino mufilimu yolowera komanso yosavuta yowuzira.

3. Silicone chitsulo chopangira chotsatira

Makulidwe akuthupi: ≤1.0mm; wamba 0.35mm 0.5mm 0.65mm;

Nkhani: Frrokilicon aloy

Zofunikira: Kutsekedwa kapena osatsekedwa;

➢ Zoyenera kulondola: Gawo 8 mpaka 10 kulondola;

➢ Glorath Height zofunika: ≤0.03mm;

4. Silicon chitsulo chopanga pepala

Kulera: kumeta ndi njira yogwiritsira ntchito makina kapena lumo. Mawonekedwe ogwirira ntchito nthawi zambiri amakhala osavuta.

➢ Kumatula: Kugwedeza kumatanthauza kugwiritsa ntchito nkhungu zosefukira, kudula mabowo etc. Njira ndizofanana ndi kumeta, kupatula kuti kusefukira kwamtunda ndi kotsika kumasinthidwa ndi nkhungu. Ndipo imatha kupanga nkhungu kuti mugule mitundu yonse ya silika yachitsulo.

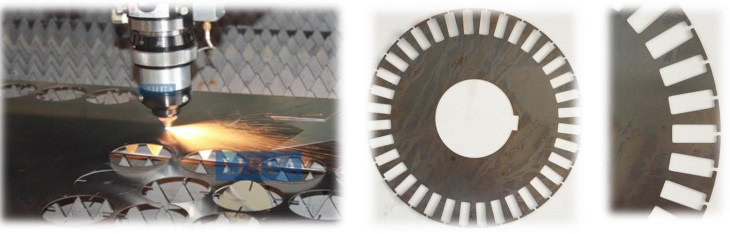

Kudula: Kugwiritsa ntchito makina odulira a laser kuti mudulere mitundu yonse ya ntchito. Ndipo pang'onopang'ono ndikukhala njira yofala yofala ya silicon steel.

- Kuyambiranso: Popeza chitsulo chachitsulo chimakhudza mwachindunji magwiridwe antchito, kotero ngati kutalika kwa burr ndikokwera kuposa 0.03mm, iyenera kuphwanyidwa musanapata utoto.

Zojambula: Chomera chachitsulo chizikhala ndi utoto wokhazikika, wowotcha wamoto wowonda.

Kuuma: utoto wa pepala lachitsulo liyenera kuwuma pamtunda winawake kenako ndikuchiritsa mphamvu zolimba, zamphamvu, zapamwamba kwambiri.

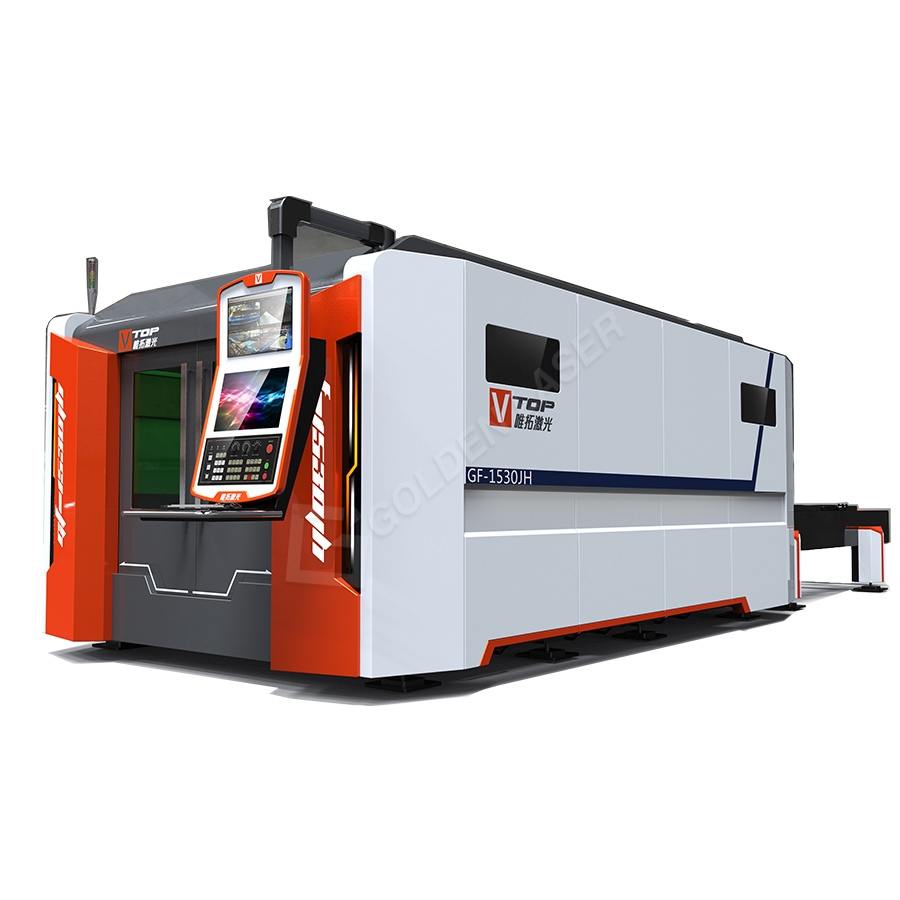

5. Njira yofanizira - kudula kwa laser

Kudula kwa laser: Zinthuzo zimayikidwa patebulo lamakina, ndipo lidzadula malinga ndi pulogalamu yoyambirira kapena scific. Kudula kwa laser ndi njira yamatenthedwe.

Magwiridwe antchito a laser:

➢ Kukonzekera kusinthasintha, mutha kukonza ntchito nthawi iliyonse;

➢ Njira yolondola, makina wamba makina ndi 0.01mm, ndi makina odulira a laser ofupika ndi 0.02mm;

➢ Sungani ndalama zochepetsetsa, mumangofunika kukhazikitsa njira ndikuwongolera magawo, kenako yambani kukonza ndi batani limodzi;

➢ Kuyika kwa phokoso laphokoso sikungatheke;

➢ Zinthu zomalizidwazo zopanda ziphuphu;

➢ Ntchito yogwira ntchito yopanga itha kukhala yosavuta, yovuta ndipo ili ndi malo osakhazikika;

➢ Makina odulira a laser amasaka;

➢ Kutsika mtengo;

➢ Kupulumutsa zinthu, mutha kugwiritsa ntchito ntchito yakugawana m'mphepete mwa pulogalamu ya Chisanja kuti mukwaniritse njira zoyenera, ndikuwonjezera kugwiritsa ntchito.

6. Mayankho a laser

Tsegulani Mtundu wa 1530