1. Urupapuro rwa silicon ni iki?

Impapuro za silicon ibyuma bikoreshwa namakuba akunze kwitwa impapuro za silicon. Nubwoko bwa ferosilikoni bworoshye magnetic ikubiyemo karubone nkeya. Muri rusange irimo 0.5-4.5% silicon kandi irazunguruka nubushyuhe nubukonje. Mubisanzwe, umubyimba uri munsi ya mm 1, niko byitwa isahani yoroheje. Ongeraho Silicon Kurwanya Icyuma Cyambere Amashanyarazi hamwe nubukungu ntarengwa bwa magnetique, kugabanya guhuza, gutakaza ishingiro (igihombo cyicyuma) na magnetic ashaje.

Urupapuro rwa Silicon rukoreshwa cyane cyane mugukora amaka y'icyuma kubanyamwe bahindura, motory hamwe namakosa.

Ubu bwoko bw'ibyuma bwa silicon bufite imiterere nziza ya electromagnetique, ni ibikoresho byingenzi byingenzi kandi byingenzi bya magneti mububasha, itumanaho hamwe ningagi.

2. Ibiranga urupapuro rwa silicon

A. Gutakaza Icyuma gito nigipimo cyingenzi cyubwiza. Ibihugu byose byo mwisi bikurikirana igihombo cyicyuma nkicyiciro, igihombo cyicyuma, urwego rwo hejuru, nibyiza.

B. Kumurwa cyane magnetic. Munsi yumurima umwe wa rukuru, urupapuro rwa Silicon rubona magnetike yo hejuru. Ingano nuburemere bwa moteri na transformer yicyuma bikorerwa nimpapuro za Silicon ugereranije numucyo, bityo birashobora kuzigama umuringa, kubikoresho byo kwikuramo umuringa.

C.Gigher Stacking. Hamwe nubuso buroroshye, busa nu mubyimba, urupapuro rwa silicon rushobora gutondekanya cyane.

D.Ubuso bufite imbaraga nziza kuri firime yo kwigana kandi byoroshye gusudira.

3.. Singine Icyuma Cyimikorere Ibisabwa

Ubunini bwibintu: ≤1.0mm; bisanzwe 0.35mm 0.5mm 0.65mm;

Ibikoresho: Fersilicon alloy

Ibisabwa bishushanyije: Gufunga cyangwa ntibifunze;

➢ Ibisabwa mu Byukuri: Icyiciro cya 8 kugeza 10 cyukuri;

Uburebure bwa Glitch Medicred: ≤0.03mm;

4. Imiterere ya silicon ibyuma

Gutinya: Gutinya nuburyo bwo gukoresha imashini cyangwa imikasi. Imiterere yimirimo muri rusange yoroshye cyane.

Gukubita: Gukubita bivuga gukoresha ibibumba byo gukubita, gutema umwobo nibindi bisa no kogosha, usibye ko impande zo hejuru no hepfo zisimburwa na convex na molds. Kandi irashobora gushushanya kubumba kugirango ikubite ubwoko bwose bwimpapuro za silicon.

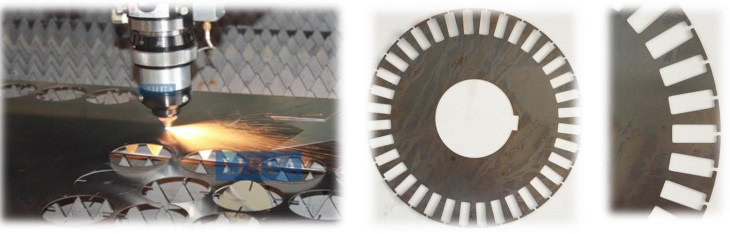

Gukata: Gukoresha imashini yo gutema Laser kugirango ugabanye ubwoko bwose bwakazi. Buhoro buhoro uhinduka uburyo busanzwe bwo gutunganya urupapuro rwa silicon.

.

Gushushanya: Hejuru ya chip yo mu ibyuma izasiga irangi hamwe nubushyuhe bukomeye, burwanya ubushyuhe hamwe na firime yoroheje.

Kuma: Irangi ryibyuma rya silicon zigomba gukama ku bushyuhe runaka hanyuma ukikiza muburyo bukomeye, bukomeye, bukomeye, bunini bwimirire.

5. Kugereranya gutunganya - gukata laser

Gukata kwa Laser: Ibikoresho bishyirwa kumeza yimashini, kandi bizagabanya ukurikije gahunda ya Preset cyangwa igishushanyo. Gukata kwa Laser ni inzira nziza.

Ibyiza bya Laser:

Guhindura ibintu byinshi byoroshye, urashobora gutunganya imirimo yo gutunganya igihe icyo aricyo cyose;

Prescial yo gutunganya ibihugu byinshi, imashini isanzwe itunganya imashini ni 0.01mm, hamwe na precar imashini yo guca ahanini ni 0.02mm;

Gutanga imfashanyigisho, ukeneye gusa uburyo nuburyo bwo gutunganya, hanyuma utangire gutunganya hamwe na buto imwe;

Guhumanya urusaku rutunganya ni ubusanzwe;

Ibicuruzwa byarangiye ntabwo biri munsi;

Couventiece Igikorwa cyo gutunganya gishobora kuba cyoroshye, kigoye kandi gifite umwanya utagira imipaka;

Imashini yo gutema Laser iratunganye kubuntu;

➢ Gukoresha igiciro;

Ibikoresho byo gukiza, urashobora gukoresha imikorere yo kugabana imiterere binyuze muri software yo kurera kugirango ugere kuri gahunda nziza yo gukora, kandi wongere ibikoresho bifatika.

6. Ibisubizo bya Laser

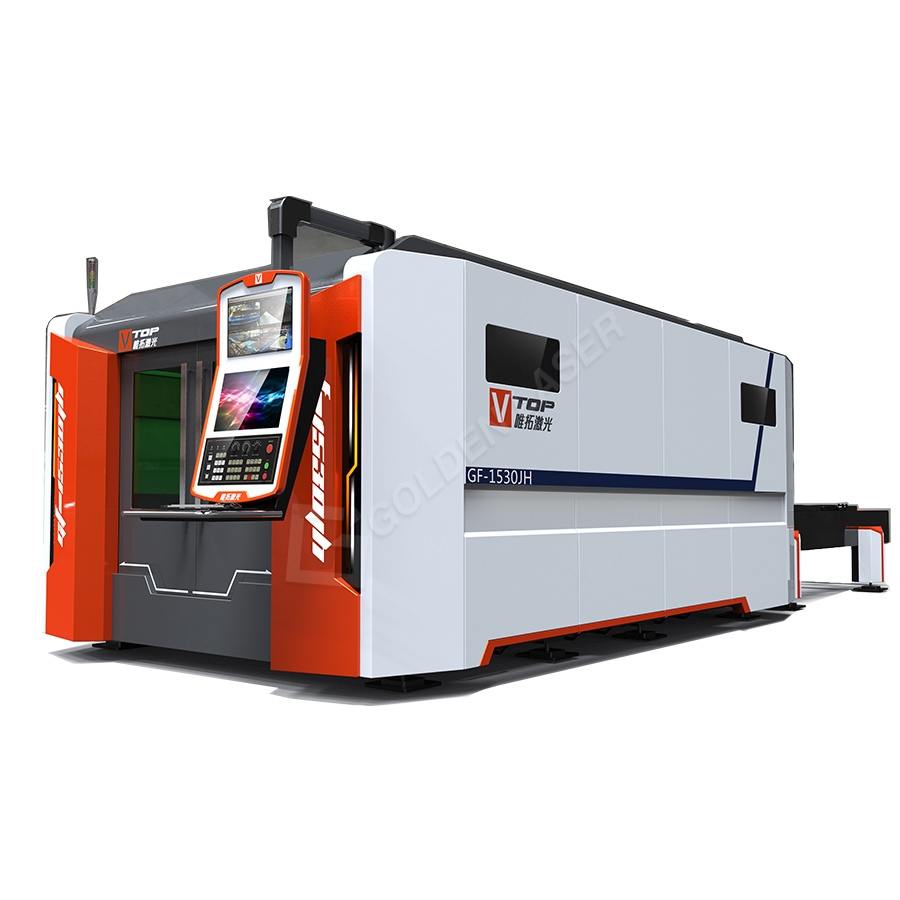

Gufungura Ubwoko bwa 1530 Claser Cutter GF-1530 Precision