Tšebeliso ea Mechini e Sehang ea Fiber Laser Tube ho Indasteri ea Sekafo

The Scarffolding e phetha karolo ea bohlokoa indastering ea kaho, ho sa tsotellehe ho haha ntlo e ncha kapa ho lokisa moaho, re ka bona mefuta e fapaneng ea scarffolding ka lehlakoreng la rona. E netefatsa polokeho ea basebetsi, katleho ea projeke, le bots'epehi ba sebopeho.

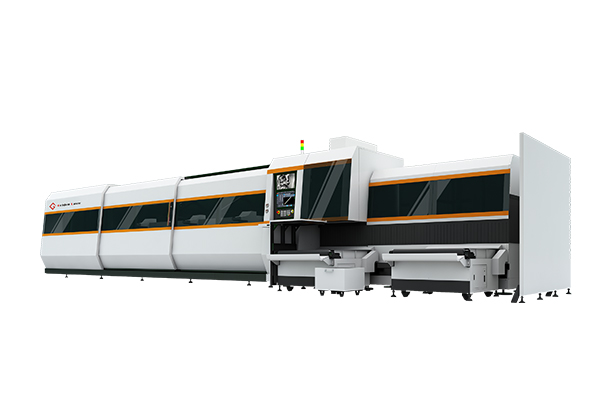

Kajeno re rata ho bua ka mokhoa oa hofiber laser tube ho itšeha mochinintlafatsa mokhoa oa tlhahiso ea moetlo le katleho.

Ka tloaelo, ho etsoa ha likarolo tsa scaffolding ho itšetlehile ka motsoako oa mosebetsi oa matsoho le lisebelisoa tse tloaelehileng tsa ho itšeha, tse kang li-cutters tsa plasma le litoche tsa oxy-fuel. Le hoja mekhoa ena e sebelitse indasteri hantle, hangata e tla le mefokolo le mathata a tlhaho.

E 'ngoe ea lintho tse ka sehloohong tse amehang ke boleng le botsitso ba likarolo tse felileng. Ha matla a fiber laser a ntse a eketseha, phello e ntle ea ho itšeha thepa ea tšepe e teteaneng e se e ntse e le mosebetsi o mongata oa ho seha mochini oa plasma.

Ho hlaha ha mechine ea ho itšeha ka laser ho entse phetoho e khōlō indastering ea scaffolding, e fana ka tharollo ea phetoho mathateng a hlahisoang ke mekhoa ea setso ea ho etsa masela. Mechini ena e tsoetseng pele e phahamisa matla a maballo a laser a matla a phahameng hore a sehe ka nepo mefuta e mengata e fapaneng ea thepa, ho kenyeletsoa tšepe, aluminium, le litšepe tse ling tse sebelisoang haholo kahong ea scaffolding.

Ho Nepaha le ho Nepaha

E 'ngoe ea litšobotsi tse hlahelletseng tsa mechine ea ho itšeha ka laser ke ho nepahala le ho nepahala ho ke keng ha bapisoa. Ho fapana le mekhoa ea ho itšeha ka letsoho, mechine ena e khona ho hlahisa libopeho tse rarahaneng, tse rarahaneng ka mokhoa o tsotehang le ho pheta-pheta. Boemo bona ba ho nepahala ke ba bohlokoa indastering ea scaffolding, moo le liphapang tse nyane haholo tsa likarolo tsa likarolo li ka bang le litlamorao tse kholo bakeng sa botšepehi ba sebopeho le polokeho ea sistimi.

Keketseho ea Tlhahiso le Katleho

Mechini ea ho itšeha ea fiber laser e boetse e fana ka lintlafatso tse kholo mabapi le tlhahiso le katleho. Mechine ena e ka sebetsa ka lebelo le phahameng, e fokotsa lisebelisoa ka katleho e tsotehang le ho fokotsa nako e hlokahalang bakeng sa ho etsoa. Sena, ka lehlakoreng le leng, se fetolela linako tse potlakileng tsa phetoho, ho fokotsa litšenyehelo tsa basebetsi, le bokhoni ba ho kopana le linako tse thata tsa merero.

Automation le Programmability

Ho feta moo, ho iketsetsa le ho hlophiseha ha mechini ena ho lumella ho kopanngoa ka mokhoa o se nang moeli oa moralo o thusoang ke khomphutha (CAD) le litsamaiso tsa tlhahiso ea lisebelisoa tsa khomphutha (CAM). Ho kopanya hona ho nolofatsa ts'ebetso eohle ea ho qapa, ho tloha ho moralo ho ea ho tlhahiso, ho fokotsa menyetla ea liphoso le ho ntlafatsa ts'ebetso ea kakaretso.

Ho feto-fetoha ha maemo le ho ikamahanya le maemo

Mechini ea ho itšeha ea fiber laser e hlahelletse ka ho tenyetseha ha eona, e khona ho sebetsana le mefuta e fapaneng ea lisebelisoa le lits'ebetso ka har'a indasteri ea sethala. Ho tloha ho sehiloeng hantle ha li-tubes tsa tšepe le maballo ho ea ho sebopeho se rarahaneng sa likarolo tsa aluminium, mechini ena e ka ikamahanya le litlhoko tse tsoelang pele tsa indasteri.

Mokhoa ona oa ho feto-fetoha o fetela ka nģ'ane ho ho rema lisebelisoa tse tala. Mechini ea ho itšeha ka laser e ka boela ea sebelisoa bakeng sa ho etsalisebelisoa tse khethehileng tsa scaffolding, joalo ka lipoleiti tsa khokahano, masakaneng, le likarolo tsa polokeho.Ka ho kopanya mekhoa e mengata ea maqheka hore e be tsamaiso e le 'ngoe, e sebetsang hantle haholo, mechine ena e thusa ho tsamaisa mosebetsi oohle oa tlhahiso ea scaffolding.

Tšireletseho e Ntlafetseng le Moshoelella

Ho phaella ho bokgoni ba bona botekgeniki, faeba laser ho itšeha mechine e boetse e kenya letsoho ho ntlafatsa polokeho le moshoelella indastering ea scaffolding. Ho nepahala le ho iketsetsa mechine ena ho fokotsa kotsi ea likotsi tsa mosebetsing tse amanang le mekhoa ea ho itšeha ka letsoho, ho theha sebaka se sireletsehileng sa ho sebetsa bakeng sa basebetsi.

Ho feta moo, mokhoa o sebetsang hantle oa matla oa theknoloji ea fiber laser le litšila tse fokotsehileng tse hlahisoang nakong ea ho seha li kenya letsoho mokhoeng o tsitsitseng oa ho etsa masela. Ho tsamaisana hona le menahano ea tikoloho ho ntse ho le bohlokoa haholo kaha indasteri ea kaho ka kakaretso e ikitlaelletsa ho amohela mekhoa e metle ea tikoloho.

Qetello

Ho kopanngoa ha mechine ea ho itšeha ka thapo ea thapo ka har'a indasteri ea scaffolding ho kentse mehla e mecha ea tlhahiso, ho nepahala le polokeho. Litheknoloji tsena tse tsoetseng pele li fetotse tsela eo likarolo tsa scaffolding li qapiloeng ka eona, li fana ka mefuta e mengata ea melemo e kenyelletsang boleng bo ntlafetseng, ts'ebetso e eketsehileng, le ts'ebetso e ntlafetseng.

Ha indasteri ea kaho e ntse e tsoela pele ho ntlafala, lekala la scaffolding le tlameha ho ikamahanya le maemo le ho amohela litharollo tse ncha ho lula li le tlholisano le ho fihlela litlhoko tse ntseng li hola tsa merero ea sejoale-joale. Kamohelo ea mechini ea ho itšeha ea fiber laser e emela letsete la leano le sa rarolleng feela liqholotso tsa hajoale tseo indasteri e tobaneng le tsona empa hape e betla tsela bakeng sa bokamoso moo polokeho, ts'ebetso e ntle le boqapi e leng motheo oa ho qaptjoa ha scaffolding.