E le toropo e bulehileng e lebopong la leoatle le setsi sa tlhahiso ea mechini ea Jiaodong le theknoloji ea tlhahisoleseling, Yantai e na le melemo e ke keng ea bapisoa tšebelisanong ea eona le liindasteri tsa Japane le Korea Boroa ka melemo ea eona e ikhethang ea sebaka. Ke eona e tsamaisang phetisetso ea liindasteri ea Japane le Korea Boroa 'me ke eona tsela e ka sehloohong ea moruo oa Japane le Korea Boroa.

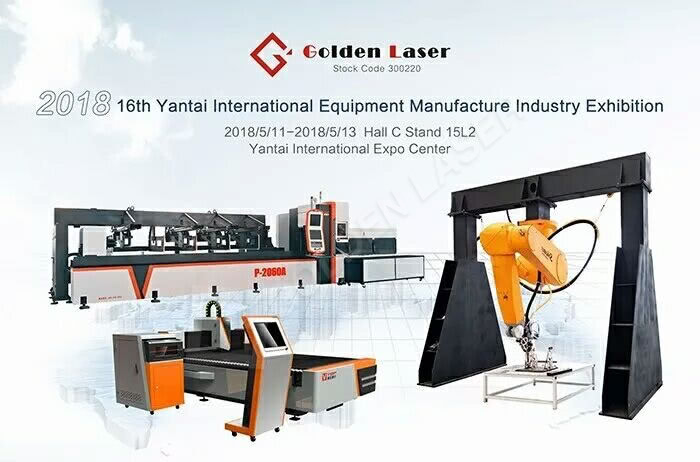

The 2018 16th Yantai International Equipment Manufacture Industry Exhibition e tla tšoaroa ka May 11th-13th, rona Golden Laser ha moetsi oa mochini oa laser re tla ea pontšong ena, lekhetlong lena re tla bonts'a Mochini o le mong oa Professional Pipe Laser Cutting Machine P2060A o nang le auto bundle loader system, One Shetting Machine Robot 0 Arm1 le Cutting Machine GF-5 Laser Mochini oa Welding. Boemo ba rona ke Hall C 15L2, amohela ka mofuthu ketelo ea hau.

Tlhahlobo ea Lipontšo 01

Mochini o Sehang oa Pipe Laser oa P2060A

Liphaephe le litlaleho li sebelisoa haholo likarolong tsohle tsa bophelo 'me li amana haufi-ufi le bophelo ba motho e mong le e mong. Ka mohlala, thepa ea ka tlung, liraka tsa lipontšo tsa liaparo, mabala a maholo a lipapali, thepa ea boikoetliso, mechine ea temo, likoloi tsa baeti, lifereko, likirini tsa oli le liindasteri tse ling. Ha tlhoko ea 'maraka e ntse e eketseha,' maraka oa ts'ebetso ea liphaephe le li-profile le ona o ntse o hola. Mekhoa e tloaelehileng ea ts'ebetso e ke ke ea hlola e finyella litlhoko tsa nts'etsopele ea 'maraka o potlakileng le mekhoa ea tlhahiso ea theko e tlaase. Ka hona, mochine oa ho itšeha oa khauta oa laser o ile oa hlaha.

Likarolo tsa Mochini

P letoto laser ho itšeha mochini ke mofuta o mocha CNC phala laser ho itšeha mochine ka boikemelo etselitsoe le ntshetswa pele ke Golden Laser. Mochine o na le tlhophiso e ntle haholo, ts'ebetso e phahameng ea ts'ebetso le ho nepahala, ts'ebetso e tsitsitseng le e tšepahalang. Tafole ea rotary e laoloang ke palo eohle ke likarolo tse ka sehloohong. E ka tšehetsa phala e kholo ka bophara ba Ø300mm. Litafole tse peli tse nepahetseng haholo tsa rotary li tsamaisoa ke li-dual-drive synchronously, kahoo liphaephe li boemong bo botle ntle le ho senyeha nakong ea ts'ebetso. Liphaephe tse ntseng li sebetsoa li nepahetse haholo, 'me li khona ho khaola li-tubes tse chitja, tse lisekoere, tse tharo, tse khutlonnetsepa, tse elliptical le mefuta e fapaneng ea li-tubes tse nang le sebopeho.

Mesebetsi e ka Sehloohong

Lisebelisoa tsa ho sebetsa: boholo ba lipeipi tsa ho itšeha ≤ 20mm (tšepe ea carbon) (ho itšetlehile ka lisebelisoa tse fapaneng), leqeba le ka fihla ho 12m kapa ho feta.

1. Ho seha mela ea li-cylindrical intersecting ea litsela tse fapaneng le bophara ba liphaephe, le ho finyella litlhoko tsa matekoane a perpendicular le a se nang leeme a liphaephe tsa lekala le liphaephe tse kholo.

2. Khaola sefahleho sa oblique qetellong ea tube.

3. Khaola liphaephe tsa makala mateanong a moeli qetellong ea moeli o tšeloa ka liphaephe tse kholo tsa lesale

4. Khaola sefahleho se fapaneng sa groove angle

5. Khaola lesoba la lisekoere holim'a tube e chitja le thekeng e chitja

6. Khaola mefuta e mengata ea phala ea tšepe

7. Khaola mefuta e mengata ea litšoantšo ka har'a tube ea lisekoere

Lisebelisoa tse sebelisitsoeng

Mochine oa ho itšeha oa laser o loketse ho seha tšepe ea carbon, tšepe e sa hloekang, koporo, aluminium, tšepe ea alloy, tšepe ea selemo, galvanized, koporo-plated, khauta, silevera, titanium le phala e meng ea tšepe.

Liindasteri tse sebelisoang

'Me e sebelisoa haholo ho lisebelisoa tse kang ho ikoetlisa, thepa ea ka tlung, pontšo, meriana, lipontšo le mechine ea temo, likarolo tsa meralo, marokho, likepe, likarolo tsa likoloi, likarolo tsa meralo le ts'ebetso ea liphaephe.

Ho feta moo, sistimi ea boikhethelo ea "auto bundle loader" e ntlafatsa boleng ba liphaephe. Ka boithuto bo tsoelang pele le boqapi ba theknoloji, Golden Laser e tla sebetsa 'moho le uena ho ntlafatsa mochini.

Tlhahlobo ea Lipontšo 02

2500W Sheet Metal Laser Cutting Machine GF-1530

GF-1530 series fiber laser cutting machine ke sehlahisoa sa moloko o mocha se nang le ponahalo e ncha e nchafalitsoeng le tlhophiso e fapaneng e thehiloeng ho mohlala oa pele, E sebelisoa haholo-holo ho sebetsa ka tšepe, ho bapatsa & ho saena, thepa ea ka tlung, likoloi le liindasteri tse amanang le tsona.

Lintlha tse ka sehloohong

Moqapi o bulehileng o fana ka ho kenya le ho laolla habonolo

Tafole e le 'ngoe e sebetsang e boloka sebaka

Terei ea setaele e etsa hore ho be bonolo ho bokella le ho hloekisa likhechana le likaroloana tse nyane

Sebopeho sa ho khanna habeli sa Gantry, bethe e phahameng ea mongobo, ho tiea hantle, lebelo le phahameng le ho potlakisa

Moetapele oa lefats'e oa fiber laser resonator (mokhoa o le mong) le likarolo tsa elektroniki ho fihlela lishiti tse tšesaane tsa ho itšeha ka lebelo le phahameng ka nako e ts'oanang li netefatsa botsitso bo phahameng ba mochini.

Lisebelisoa tse sebelisitsoeng

Haholo-holo bakeng sa tšepe ea carbon, tšepe e sa hloekang, galvanized steel, alloy, titanium, aluminium, koporo, koporo le maqephe a mang a tšepe.

Liindasteri tse sebelisoang

Moetso ona o etselitsoe ka ho khetheha bakeng sa ts'ebetso ea letlapa la tšepe, lets'oao la papatso, ho etsa khabinete ea motlakase, likarolo tsa mochini, lisebelisoa tsa kichineng, likoloi, metjhini, mesebetsi ea matsoho, mahare a saha, likarolo tsa motlakase, indasteri ea mahlo, letlapa la selemo, boto ea potoloho, ketlele ea motlakase, lisebelisoa tsa ho lekanya thipa, mabone a sekoti, mokhabiso oa mamati le lifensetere le tse ling.

Tlhahlobo ea Lipontšo 02

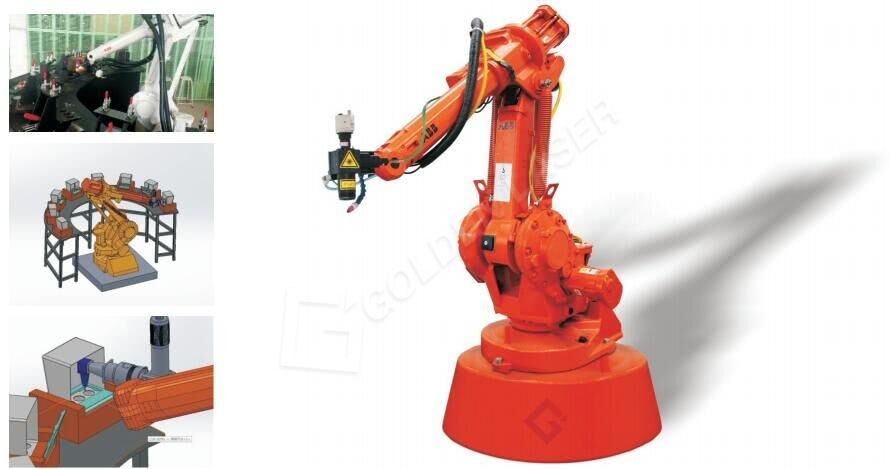

3 Mochini oa ho tjheselletsa Laser oa Robot Arm

Laser welding e na le bophahamo ba bophara ba sebaka se senyenyane sa welding, seam e moqotetsane oa weld le phello e ntle ea welding. Ka mor'a ho cheselletsa, ha ho hlokahale phekolo e 'ngoe kapa phekolo e bonolo feela. Ho feta moo, welding ea laser e sebetsa maemong a mangata a thepa mme e ka tjheseletsa lisebelisoa tse fapaneng tse fapaneng. Ho na le melemo e lumellang hore laser welding e sebelisoe haholo mefuteng ea mekhoa e nepahetseng ea ho cheselletsa.

Lintlha tse ka sehloohong

1) E kopantsoe ka ho phethahetseng le letsoho la liroboto le tsebahalang lefatšeng ka bophara joalo ka ABB, Stabuli, Fanuc le mochini oa welding oa fiber laser o ka khonang ho etsa tlhahiso ea othomathike ho fihlela holimo.

2) Tšebelisano-'moho ea 6-axis e etsa sebaka se seholo sa ho sebetsa 'me se ka fihla sebaka se selelele e le ho etsa ts'ebetso ea ho cheselletsa pina efe kapa efe ka har'a sebaka sa ho sebetsa.

3) Ka lebaka la sebopeho se kopaneng le letsoho le lesesaane la liroboto, e khona ho hlokomela ts'ebetso e phahameng le haeba sebaka sa ts'ebetso se na le lithibelo tse ngata.

4) Lebelo la ts'ebetso le boemo bo ka fetoloa ho fihlela katleho e ntle ka ho fetisisa ea tlhahiso ka lihlahisoa tse ngata.

5) Lerata le tlaase, linako tse telele tsa tlhokomelo ea tloaelo, nako e telele ea bophelo.

6) Letsoho la roboto le ka laoloa ke terminal e tšoaroang ka letsoho.

Lisebelisoa tse sebelisitsoeng

Lisebelisoa tsa ho tjheseletsa ka laser ke lintho tse entsoeng ka tšepe haholo: joalo ka tšepe e sa hloekang, alloy ea aluminium, tšepe ea k'habone, tšepe e bonolo, koporo, koporo, lakane e entsoeng ka masenke, litšepe tse sa tloaelehang, jj.

Liindasteri tse sebelisoang

Fiber laser welding e sebelisoa haholo libeteri, hlobo, lisebelisoa tsa elektroniki, hardware, lisebelisoa tsa ntlo, lisebelisoa tsa kamore ea ho hlapela, li-super capacitor, likarolo tsa likoloi, lisebelisoa tsa motlakase tse nyane, sefofane, letsatsi, likhalase, mabenyane, lisebelisoa tsa bongaka, lisebelisoa tsa lisebelisoa, puisano ea optical jj.