Uyini umshini wokusika amashubhu we-laser othomathikhi?

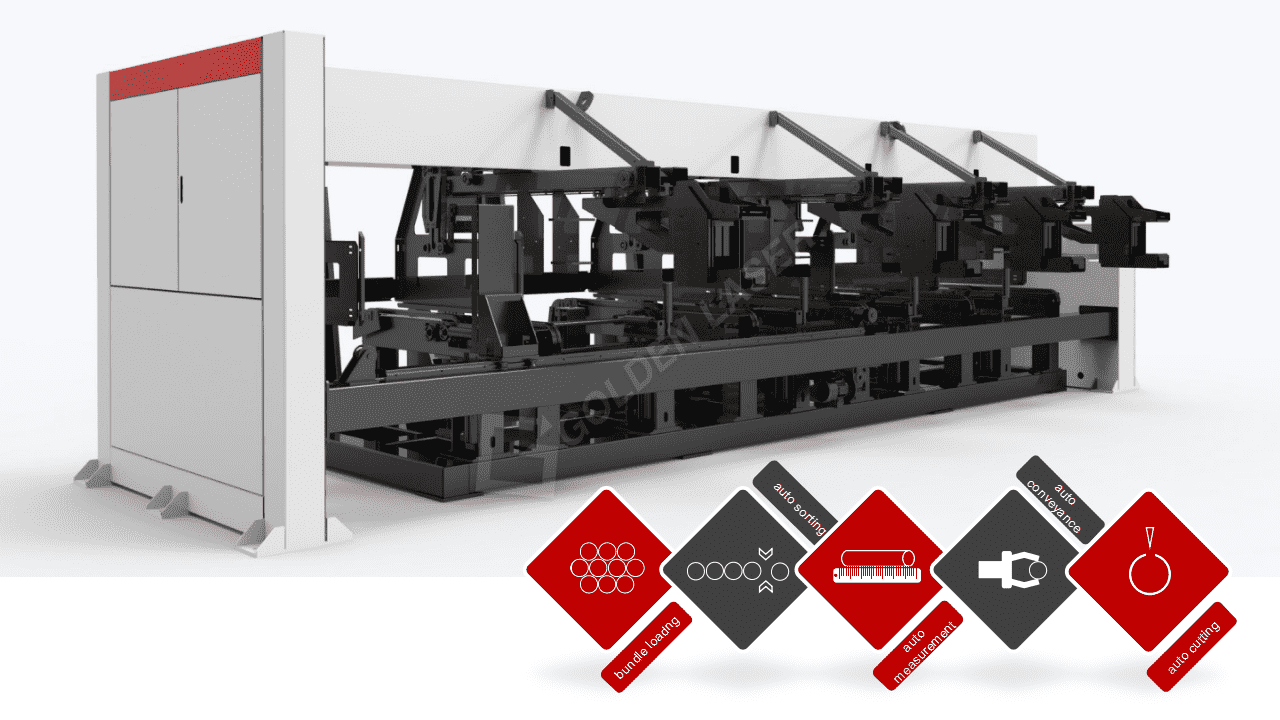

Umshini wokusika amashubhu we-laser othomathikhiokuhlanganisa i-tube automatic loading system, engalayisha ngokuzenzakalelayo ishubhu eliyindilinga, ishubhu yesikwele, iphrofayili, namanye amashubhu amise okukhethekile. Konga amandla abasebenzi bakho futhi kwandisa ukusebenza kahle kokukhiqiza.

Kungani kufanele ngisebenzise isilayishi seshubhu esizenzakalelayo ukusika ishubhu lensimbi?

Ngesistimu yokukhetha ezenzakalelayo engalayisha ishubhu ukusika ngayinye ngayinye. Umsebenzi wokulinganisa okuzenzakalelayo uqinisekisa ukuthi ishubhu ubude obulungile ngaphambi kokusika, okunciphisa isixwayiso ekukhiqizeni kusindisa isikhathi namandla akho.

Ungayikhetha kanjani i-automatic tube loader efanelekile ngokwesidingo sakho sokukhiqiza?

Ngokuvamile sizoqinisekisa ukuthi yiluphi uhlobo lweshubhu ovame ukulicubungula, uma usika amashubhu ayindilinga kuphela, isistimu yokulayisha okuzenzakalelayo yeshubhu eyindilinga iyoba yisinqumo esingcono kakhulu, ngoba iyashesha ekuphakeleni amashubhu ayindilinga, futhi izindleko zesistimu yokulayisha ngokuzenzakalelayo zizoba ngcono. . Ngezansi ishubhu eliyindilinga lokulayisha isistimu yereferensi yakho.

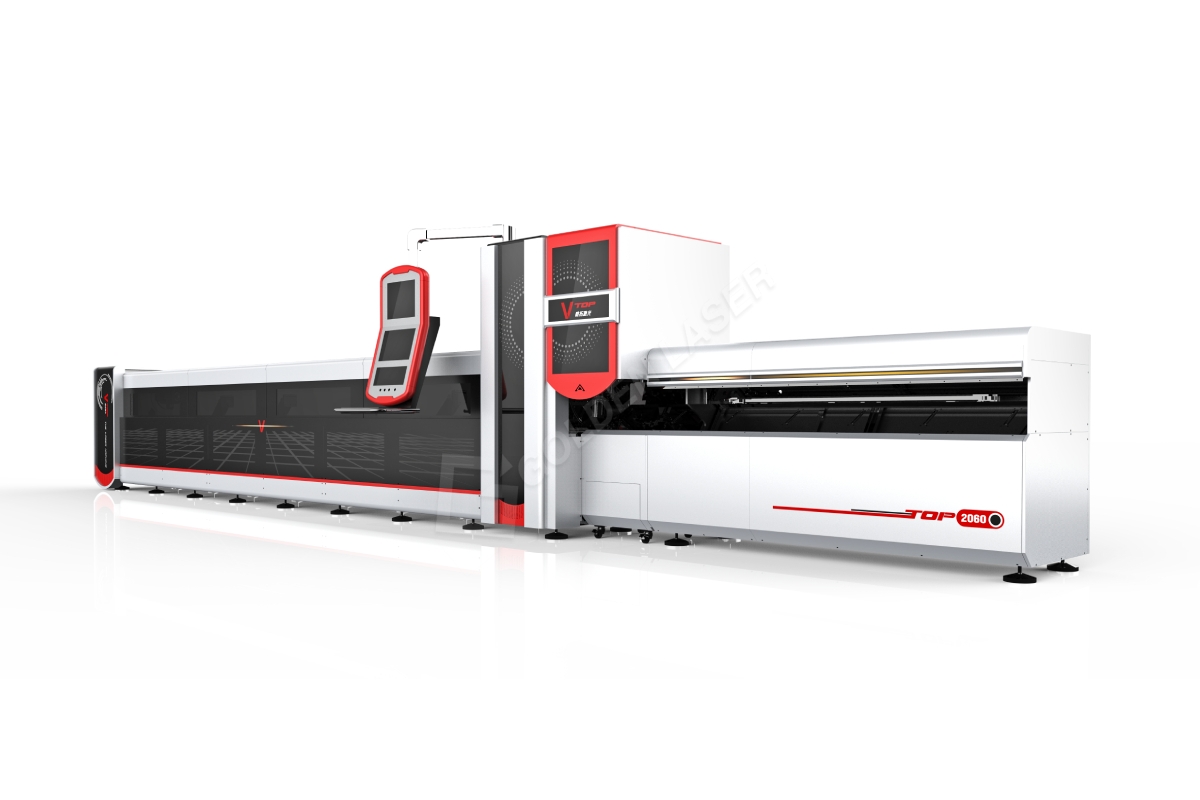

Kokubili ukulayisha kweshubhu eliyindilinga nesikwele, isilayishi esizenzakalelayo seshubhu esijwayelekile sizohlangabezana nazo zonke izimfuno zakho, njengomsebenzi omningi, intengo izokhuphuka. Ungakhetha kuphela isiphakeli seshubhu esingamamitha ayi-6 noma amamitha angu-8 ubude ngokuya ngosayizi weshubhu lakho.

Ingabe lukhona uhlelo olushibhile lokulayisha ishubhu lomshini wokusika amashubhu we-laser?

Uma ungenaso isabelomali esanele sohlelo lokulayisha amashubhu futhi unamaphrofayili ahlukene, unaso isixazululo sokusisika? Khona-ke lesi siphakeli se-Semi-automatic tube sizohlangabezana nesidingo sakho. Isebenzisa ukwakheka kwesakhiwo sesiteshi, ungabeka ishubhu ohlelweni lokuphakelayo ukuze ulungiselele ngaphambi kokuphakela umshini wokusika ishubhu le-laser.

Kula mashubhu ahlukene angenhla, okuphakelayo kweshubhu okuzenzakalelayo kungasebenza nezinhlobo zethu ezihlukene zemishini yokusika ishubhu ye-laser ukuze kwandiswe umkhiqizo wakho wokukhiqiza futhi wonge izindleko zakho zokukhiqiza.

Ukuze wenze ngokwezifiso isidingo sokusika amashubhu, pls zizwe ukhululekile ukuxoxa nathi.