Imishini yokusika ye-Laser Tube yenza okungaphezu kokusika izinhlobo ezahlukahlukene zezinqubo futhi zihlanganise izinqubo. Baphinde basuse ukuhanjiswa okubonakalayo kanye nokugcinwa kwezingxenye ezifuywayo, okwenza isitolo sigijime kahle. Kodwa-ke, lokhu akuyona ukuphela kwayo. Khulisa ukubuyiselwa kwemali kusho ukuhlaziya ngokucophelela ukusebenza kwezitolo, ukubukeza zonke izici zomshini nezinketho ezitholakalayo kanye nezinketho, bese ucacisa umshini ngokufanele.

Kunzima ukucabanga ukufeza ukusika okuphelele kweshubhu - noma ngabe imisebenzi yokusebenza iyindilinga, isikwele, isikwele, noma i-asymmetrical esimweni-ngaphandle kwama-lasers. Amasistimu we-Laser aguqule inqubo yokusika ishubhu, ikakhulukazi maqondana nobukhulu obuyinkimbinkimbi. Umshini onjalo udinga ukutshala imali okuphambili kokuqala, ikakhulukazi uma usebenza ngosayizi omkhulu weshubhu futhi wethule ama-automation nobunye ubuchwepheshe obusha kwinqubo yokukhiqiza, ngakho-ke uzodinga ukuhlela ngokucophelela ukuze uqinisekise ukuthi ukusika kweshubhu le-laser kubiza inkampani yakho.

Ekugcineni, udinga ukucubungula okuguquguqukayo okuningana ngaphambi kokuthatha isinqumo sokuthenga aumshini wokusika we-laser; Idizayini yomkhiqizo, inqubo elula, ukuncishiswa kwezindleko, nezikhathi zokuphendula ziphakathi kokugxeka kakhulu.

Izici zomkhiqizo

Ukusika kwe-laser kungaziboleka emiklamo emisha ngokuphelele yomkhiqizo. Imiklamo emisha neyinkimbinkimbi kulula ukuyicubungula ne-laser futhi ingenza umkhiqizo uqine futhi uthande kakhulu isisindo ngaphandle kokukhanyisa amandla ngaphandle kokudela amandla. I-Tube Laser Excel ekusekeleni inqubo yomhlangano we-tube. Izici ezikhethekile zokusika ama-laser ezivumela amaphrofayli we-tube ukuba agobe noma ajoyine kalula angaba lula ukushiyelwa kanye nomhlangano omkhulu futhi asize ukunciphisa izindleko zomkhiqizo.

I-laser ivumela opharetha ukuthi anciphise izimbobo futhi ahambisane ngqo esigabeni esisodwa sokusebenza, eqeda ukuhanjiswa okuphindwayo kwezinqubo ezansi komfula (bheka umfanekiso 3). Esibonelweni esisodwa, okwenza i-tube uxhumano ne-laser esikhundleni sokubona, ukugaya, ukumba, ukukhunjulwa kanye nokuphathwa kwezinto ezihambisana nakho kunciphise izindleko zokukhiqiza ngamaphesenti angama-30.

Ukuhlelwa okulula okuvela kumdwebo osuselwa kwikhompyutha Hhayi nje kuphela amasethi we-Tube Laser Press ngokushesha, kepha isikhathi sokusetha sincane, ngakho-ke ungenza izingxenye zesikhathi sokunciphisa izindleko zokusungula.

Ukuqhathanisa umshini kuzinhlelo zokusebenza

Ngemuva kokuthola ukusungulwa kwezinyathelo zakho zokukhiqiza ezijwayelekile, isinyathelo esilandelayo ukubukeza izici ezikhona bese unquma ukuthi yikuphi okubalulekile.

Amandla okusika. Khumbula ukuthi iningi lama-lasers amashubhu ahlome abathengisi abakhulula ama-2 KW kuya ku-4 kw wamandla wokusika. Lokhu kwanele ukusika ubukhulu obujwayelekile be-tubing yensimbi emnene (5/16 inch) kanye nobukhulu obujwayelekile be-aluminium ne-tubing yensimbi (¼ in.) Ngokucophelela. Izindwangu ezihlelwa amanani amakhulu we-aluminium nensimbi engenasici zizodinga umshini ekugcineni kwebanga lamandla, kanti izinkampani ezisebenza ngensimbi emnene.

I-Laser Tube yokusika yomshini we-P3080 3000w yamashubhu acubungula e-Australia

Amandla. Umshini womshini, uvame ukukalwa ngesisindo esiphezulu ngonyawo ngonyawo, kungenye indlela ebalulekile.

Amashubhu eza ngosayizi ahlukahlukene ajwayelekile, ngokuvamile kusuka kumamitha angama-20 kuye kwangama-30 futhi kwesinye isikhathi isikhathi eside. Umkhiqizi woqobo woqobo noma umenzi wenkontileka oda ama-tube kumasayizi ngokwezifiso ukunciphisa isikhafu ngakho-ke kufanele abheke umshini ohambelana nosayizi ojwayelekile wezinto ezibonakalayo. Ukukhetha kuba yinkimbinkimbi ngokwengeziwe ezitolo zemisebenzi. Amashubhu avela ku-mill ajwayelekile angama-24 ft Kulesi silinganiso usayizi, umthamo ojwayelekile wesisindo wohlelo lwe-Tube Laser lungaba ngamakhilogremu angama-27 ngonyawo ngalunye.

Umthwalo wezinto ezibonakalayo nokulayisha. Enye into ekukhetheni komshini amandla ayo ukondla ngezinto ezingavuthiwe. Umshini we-laser ejwayelekile, usika izingxenye ezijwayelekile, ugijima ngokushesha kangangokuba izinqubo zokulayisha ezenziwa ngesandla azikwazi ukuqhubeka, ngakho-ke imishini yokusika yeshubhu ngokuvamile iza nesithambisi esifinyelela ku-8,000 lbs. ngezinto ezibonakalayo kumagazini. Umthwalo wehlukanisa amashubhu bese uwalayisha ngamunye ngamunye emshinini. Umthwalo we-Bundle futhi angahambisa amashubhu ambalwa angavuthiwe egazini le-buffer ukunciphisa izikhathi zokulayisha phakathi kwamashubhu afinyelela ku-12 imizuzwana. Ukushintshwa kusuka kusayizi owodwa weshubhu kuya kwenye kwenziwa elula yindlela ezenzakalelayo ngaphakathi komthwalo. Konke ukulungiswa okudingekayo ngosayizi omusha weshubhu kusingathwe ngumlawuli.

Lapho kunesidingo sokuphazamisa ukukhiqizwa okukhulu komsebenzi omncane, kubalulekile ukuba nezinketho zokulayisha. U-opharetha wema ukukhiqizwa kugijime, alayishe ngesandla futhi acubungule amashubhu ukuqedela umsebenzi omncane, bese uqala kabusha ukukhiqizwa okusebenzayo. Ukulayisha kuyaqala ukuzodlalwa. Uhlangothi oluthulayo lwemishini yama-tubes aqediwe luvame ukuvame ukuba yi-10 ft.

Ukutholwa komthungo kanye nokwakheka. Amashubhu we-Welded asetshenziswa emikhiqizweni ekhiqizwayo engaphezu kwamashubhu angenamthungo, futhi umthungo we-weld ungaphazamisa inqubo yokusika i-laser futhi mhlawumbe nomhlangano wokugcina. Umshini we-laser ofakwe i-Hardware efanelekile ngokuvamile angathola imithungo ebekiwe evela ngaphandle, kepha kwesinye isikhathi ukuphela kweshubhu kufihla umthungo. Uhlelo olujwayelekile lokufushanisa lwe-seam-sensing lusebenzisa amakhamera amabili nemithombo emibili yokukhanya ukubheka ngaphandle nangaphakathi kweshubhu ukuthola umthungo we-weld. Ngemuva kohlelo lombono luthola umthungo we-weld, isoftware yomshini kanye nohlelo lokulawula lujikeleza ishubhu lokunciphisa umthelela we-weld sead kumkhiqizo ophelile.

Iningi lezinhlelo ze-tube laser zinganciphisa ukujikeleza, isikwele, kanye nama-tubing amanxantathu, kanye namaphrofayili anjenge-teardrop bobunjwa, i-angle iron, nesiteshi se-C-CH. Amaphrofayili we-Asymmetrical angaba yinselele ukulayisha nokugcina kahle, ngakho-ke ikhamera ongayikhetha ngokukhanyisa okukhethekile kuhlola ishubhu ngesikhathi senqubo yokulayisha futhi ilungisa iphrofayili etholakele. Lokhu kuqinisekisa ukulayisha okuthembekile nokusika amaphrofayili we-asymmetrical.

Ukusika ikhanda. Ukusika kwe-Bevel kubalulekile kumashubhu wokusika afanele ndawonye ukufudumala. Ukusika kwe-Bevel kudinga ikhanda lokusika elithatha ama-degrees angama-45 kunoma iyiphi inqubo yokusika. Ngokuphepha okwengeziwe kwenqubo ye-BEVEL yokusika eyinkimbinkimbi, ikhanda lokusika lingavikelelwa ama-magnets. Endabeni yokushayisana phakathi komsebenzi we-tubular Kungavulwa ngemizuzwana nje embalwa. Kungenzeka futhi ukuhlanganisa ikhanda lokusika le-bevel nge-axis eyengeziwe enesivinini esikhulu sokushesha kokusika, okuvumela ukwanda kokukhiqiza kwemishini okusondela ngamaphesenti angama-30.

Khulisa ukusebenza kahle

Ngemuva kokuhlonza inani uhlelo lokusika lwe-Laser Tube olungenisa inqubo yokukhiqiza, udinga ukumisa leyo mishini yohlelo lwakho lokusebenza. Isibonelo, kufushane kakhulu uhlelo lokulayisha kungawuthinta kakhulu ukusebenza kahle kwezindawo eziqediwe, okukhulisa isikhafu, ngenkathi kudala uhlelo olungaphezulu ludinga ukutshalwa kwemali okuphezulu okuthe xaxa kanye nesikhala saphansi ngaphezulu kunokudingeka kakhulu. Ngaphezu kokufuna izeluleko kubakhiqizi bohlelo, uzodinga ukusika izingxenye zesampula futhi uhlole yonke inketho etholakalayo ukuze uqiniseke ukuthi utshalomali lwakho luphumela ekubuyeni kwakho okungcono kakhulu.

Umsiki we-leaser wepayipi esizeni sethu samakhasimende

I-Fibre Laser Tube Pipe Cutter 3000w P3080 yamashubhu acubungula eFrance

I-autoshotic bundleader garefer fiber laser pipet umshini umshini p3080a e-USA

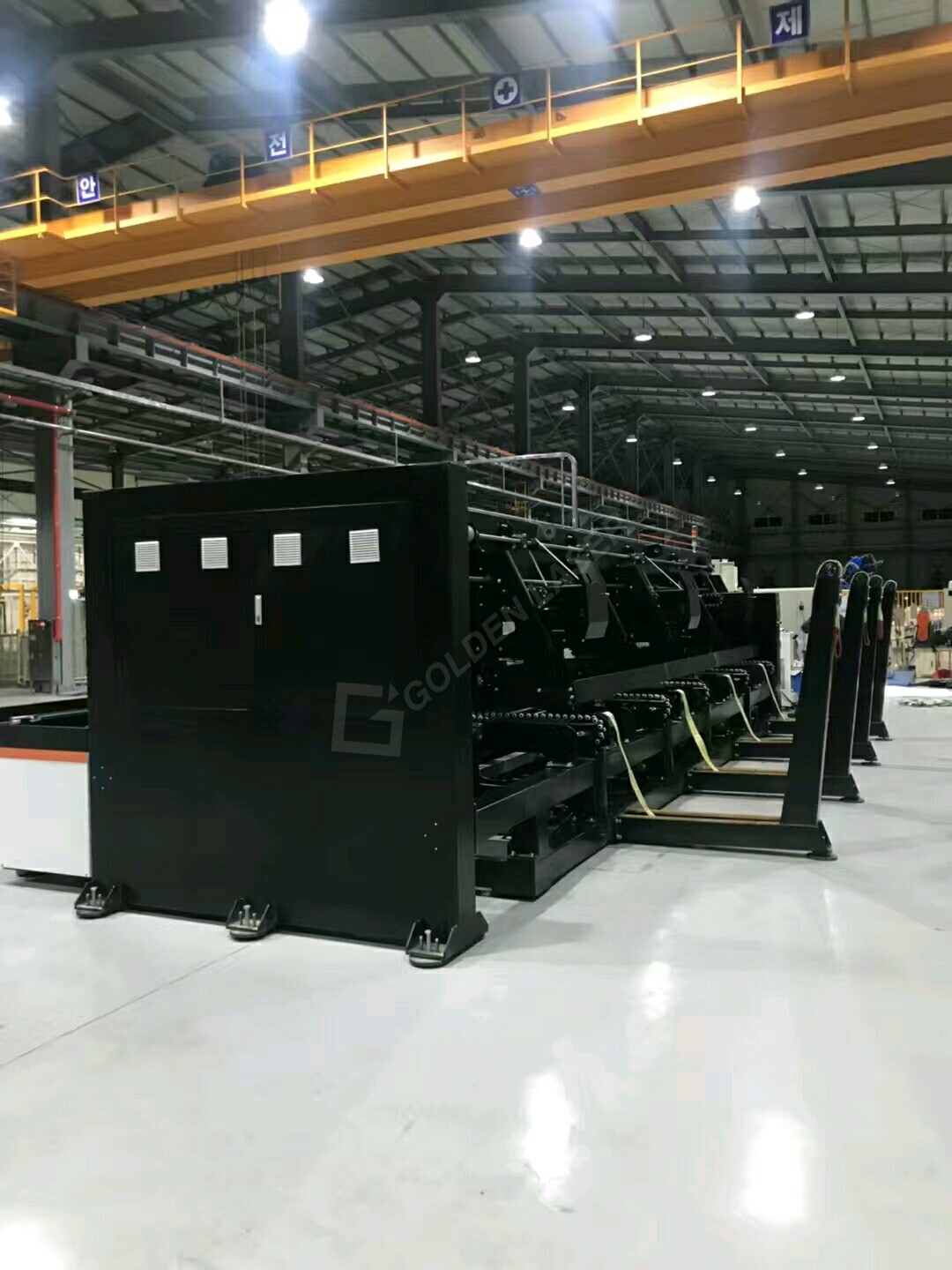

Amasethi amane amapayipi we-laser cutter p2060a yefenisha yensimbi eKorea

Umshini wokusika weshubhu we-tube p2060a ukucubungula kwamapayipi eMexico

I-Pipe Laser Cutting Machine P3080 yokucubungula kwamapayipi eFrance

Isembozo esigcwele se-CNC Pipe Laser Cutting Machine p060a e Taiwan

I-Fiber Pipe Laser Cutter P2080A eKorea

I-P30120 Metal Tube Laser Cutting Machine ngesakhiwo sensimbi eChina