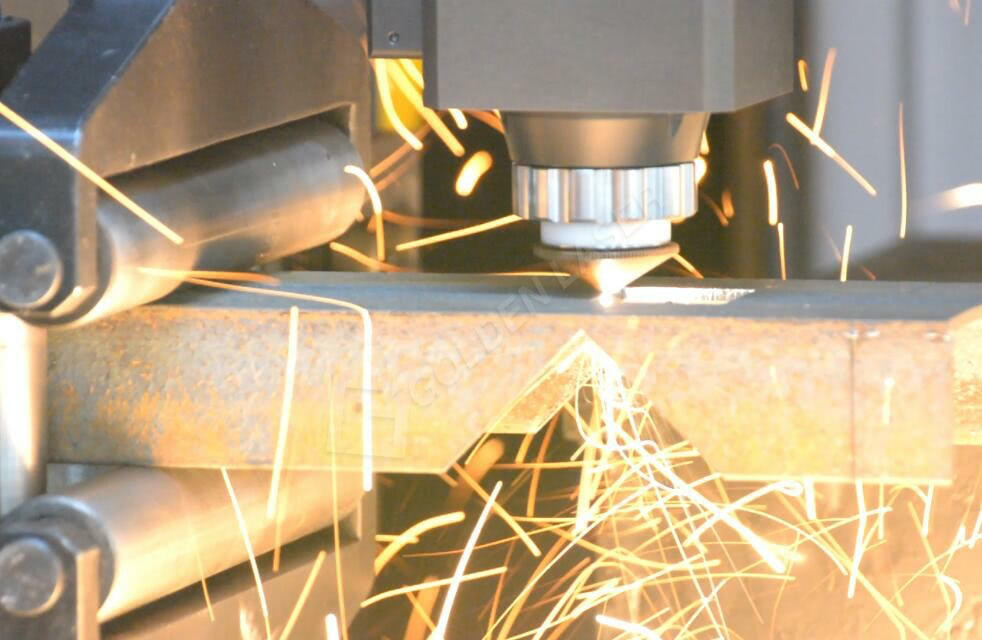

I-Golden Laser Pipe Laser Cutting Machine p uchungechunge I-Fiber Laser Resonator Lophistical Lonator i-ILight noma i-IPG kusuka e-USA, futhi i-Fiber Laser Cutting Head kusuka embhedeni weSwitzerlands Cnc

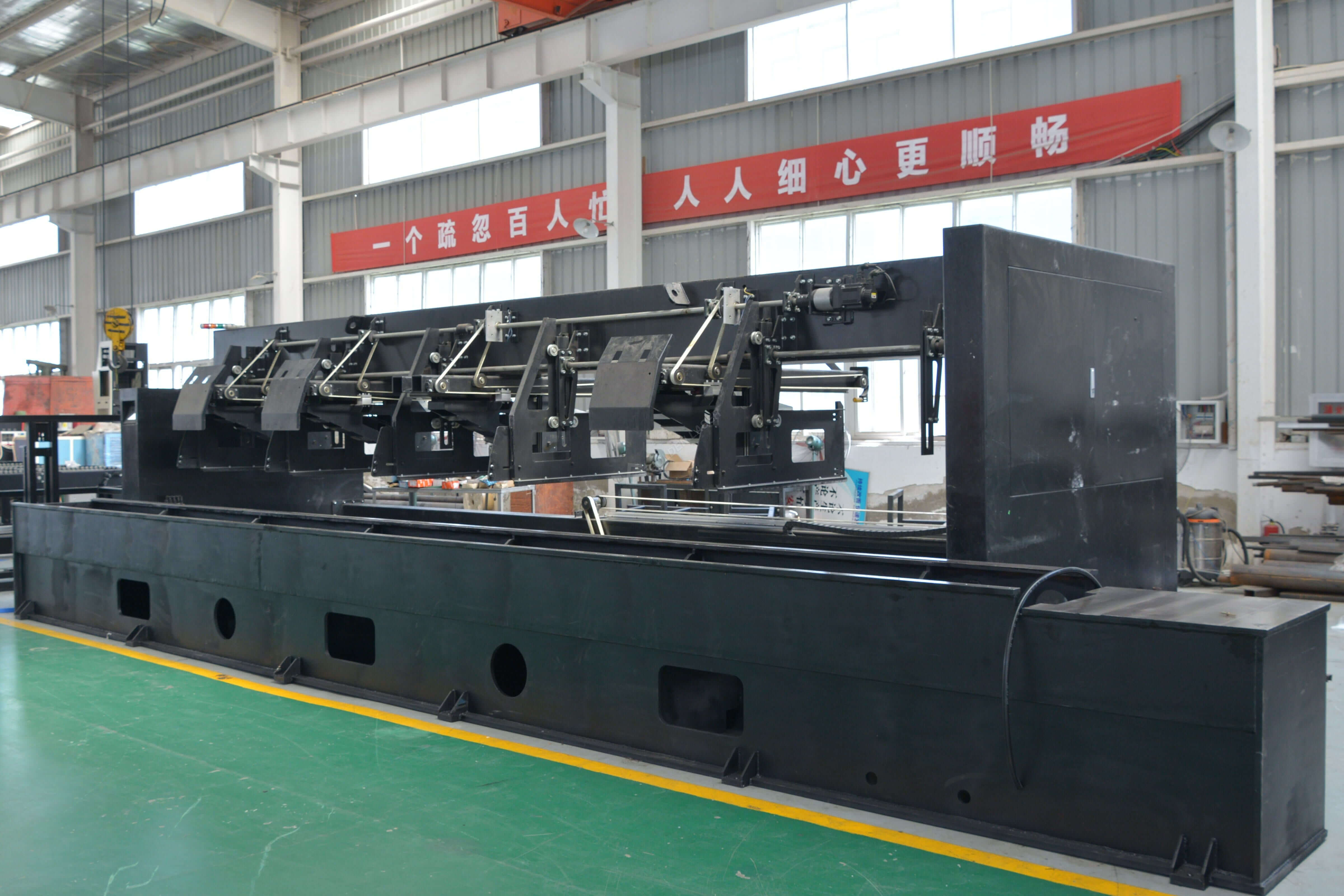

Ngemuva kokushisa okuphezulu kokushisa nokunemba kwemishini ngomshini omkhulu we-CNC milling, unobulukhuni obuhle nokuqina. Ngokwamukela izingxenye eziphezulu ezingeniswayo ezingeniswayo, njenge-Linei Guide drive, i-servo motor ephezulu ye-servo motor, i-aluminium beam, inqubo ephezulu yokushisa, amandla aphansi, umshini omuhle, umshini ubedumile kakhulu emakethe noma ebanzi.

1.Ubude bepayipimu obuncane bungaphakathi kwe-20mm, ecindezela imingcele.

2.U-CNC Pipe Cutting Machine kulula ukuyifunda futhi usebenze, opharetha oyedwa angalawula imishini emibili ngesikhathi esisodwa, futhi abesifazane bangayisebenzisa. Ngokwenhlosweni okunamandla kokulawula, umshini kulula ukuqala futhi ume; Ngemuva kokuthi inqubo yokusika ipayipi isiqediwe, umshini uzoma ngokuzenzakalelayo, futhi amapayipi aqediwe asebhokisini eliqoqiwe.

I-3.Twice Vibration ukuguga kanye nokukhulisa ukuqinisekisa umshini ngokuqina okuhle futhi anti-shake, ngakho-ke ukunemba komshini kuzohlala iminyaka engu-15.

I-4. Ukufakwa kwesiGungu kwamukela konke okwenziwa okuphezulu okufana namathuluzi wokulinganisa nama-laser interfemporeters ukuqinisekisa ukufakwa kwe-55mm ubukhulu bokufakwa kwe-dum.

I-5. Uhlelo oluzenzakalelayo lokudla kwamapayipi lwenza inani elikhulu lokudla kwamapayipi nokusika ngokuzenzakalelayo, futhi ukondla kunembile futhi kuyashesha. I-automated esebenza kahle, ayithambekele emzalweni omncane kanye nokulondolozwa kwabasebenzi. Uhlelo oluzenzakalelayo lokudla lusekela amapayipi angama-800 * 800mm Bunch, isisindo esiphezulu sokulayisha siyi-25kg ngemitha ngayinye.

I-6

7. Ingashintsha ngokuzenzakalelayo umugqa wokuhola futhi uvikele ukushayisana ngokuya ngezimbobo ezihlukile, bese ulinganisa ngokuzenzakalela i-veector ukuvikela ukushayisana, le misebenzi isebenza kahle kumashubhu abunjwe ngokukhethekile. I-algorithm ye-calibration nayo izohluka ngokuya ngamashubhu ahlukile.

8. Kungakwazi ukwenza izingxenye ezihlangene izingxenye zokudweba ukwakheka ku-batch ngefomethi ye-Excel, elula futhi yonga isikhathi esiningi sokudweba.

9. Sizoshintshana ngezingxenye ezithile, izingxenye ezibalulekile noma ubuchwepheshe obuhle ukufezekisa umshini wokusika wepayipi, bese wenza umthamo wokukhiqiza, ukusebenza, ukusebenza kahle njll. Ngakho-ke lokhu kuthuthuka kunwebisa impilo ye-serive ye-leser ye-laser ye-laser, kusindisa izinto ezingavuthiwe kanye nabasebenzi, kunciphisa izindleko.

I-10. Ukusika okuhle nokusika isivinini, ukusika kwe-sppeng kufinyelela kumamitha angama-90 ngomzuzu, futhi i-angle yokusika iyashintsha. Nge-automation ephezulu, igcina isikhathi esiningi somsebenzi. Imishini kulula ukuyigcina ekhulisa impilo yayo yenkonzo.

11. Njengoba ukusekelwa okuhlukahlukene kobubanzi kunobutho obuqinile bokuqubuka ngamandla, ngakho-ke ipayipi ngeke liguqukele ukwenza ukunemba okungalungile. Futhi umhlahlandlela wesitimela usebenzisa idivaysi yokuthambisa ezenzakalelayo ngakho-ke akukho shintsho lokuma komshini.

12. Ipuleti yobuso bokuphela kanye ne-slider groove yangaphakathi konke kungubufakazi bothuli, futhi ne-chuck emuva inedivayisi yokukhipha uthuli, konke lokhu kungafaka ukusebenza kwezinzile ngomshini.

13. Umshini ulungele ukusika izinsiza zensimbi eziphakeme ezifana nethusi, i-aluminium, ipayipi eligcwalisiwe kanye nabanye. Futhi isekela umjikelezo, isikwele, unxande, unxantathu, i-pentagonal, i-pentagonoral, i-angle, i-angle, isiteshi, i-irregular kanye nezinye izinhlobo zokwakhiwa komkhiqizo omusha.

14. Imishini ithuthukiswe ngezinhlelo zokusebenza ezibanzi zemboni kanye nokuhlangenwe nakho okuningi kokufaka. Noma ngabe kungukulayishwa kwezinto ezibonakalayo noma ukusika, inani elinembile lokulinganisa lepayipi ngalinye lisetshenziselwa ukubala ngokuzenzakalelayo ukusetshenziswa okusebenzayo kokusetshenziswa okuphezulu futhi kugcinele okubonakalayo kuze kube sezingeni eliphezulu. Imfucuza ngokwemvelo iyancipha.

15. Alukho uthuli futhi awukho umsindo, lwenzelwe ngokukhethekile imboni yokuvikela imvelo.

16. Ungumnikazi we-auto onqenqemeni umsebenzi, uma ipayipi libandlululo, ikhanda lokusika lingakhomba ngokuzenzakalelayo futhi lipheleze ama-bias.

17. Amapayipi ngaphakathi kwebanga lokubekezelela okusethwe. Uma ubude bepayipi bungafanele, kuzolaka.

18. Ungabona ukusika okunembile kwazo zonke izinhlobo zokwakheka okuyinkimbinkimbi ezingakwazi ukutholakala ngokudumbulwa okufana nokusika umgodi, ukusika, ukusika iphethini elinzima, imigqa yokuhlukanisa njll.

19. Ngepayipi eliminyene linokuningi okugxile kokuguquguqukayo okuzenzakalelayo, okungakhulisa izinga lokukhishwa ngaphandle kokuqhuma komgodi; Ukwenza ngcono ukusebenza kahle nokunciphisa isikhathi sokusika; Ukushintshaniswa kwepayipi elincanyana kanye nepayipi eliwugqinsi kungathola ngokuzenzakalelayo amapharamitha ahambisanayo kusuka kumtapo wezincwadi wenqubo.

20. Ngomshini wepayipi wepayipi we-P Series sinamamodeli amathathu nge-P020 yakho ye-P2060, P3080 ne-P30120, ngakho-ke kungacubungula ubude bepayipi 6000m, 8000mm, 12000mm.

21. Ipayipi elingaphandle kwepayipi kufanele libe phakathi kuka-320mm noma i-diagonal kungakapheli 320mm.

22. Umshini ungasika i-arc, i-groove, oblique.

23. I-chuck iguqula ngokuzenzakalelayo amandla okuqhuma ngokusho kohlobo lwe-tube, ububanzi kanye nobubanzi obudongeni njll.

24. Isoftware yokulawula umshini inekhono lokufunda eliqinile nesidleke esihlakaniphile; Ingacubungula umklamo we-3D ngokuya ngohlelo lweGolide Laser Cad-Cam.

25

26. Izingxenye ezisezingeni eliphakeme ezingeniswayo, i-pneumatic accone

I-NTS esetshenziswe emshinini ukwamukela izinhlobo zamangeniso, ngakho-ke kungaqinisekisa ukuthi uhlelo lomshini luzinzile futhi luhlangabezana namazinga okuthekelisa.

27.Ukunciphisa ukucacisa ± 0,03mm.

28. Umshini uyakwazi ukusika ibhande ne-groove yenqubo.

29.Ikhwalithi yokusika umshini iphakeme. Ipayipi ngeke lilimaze ngokushisa, futhi udonga lwangaphakathi lubushelelezi ngemuva kokusika, ingaphezulu libushelelezi futhi asikho isidingo sokugaya kwesibili, ama-zero burr ngaphandle kwe-wheldink.

30.Umshini ungasika ama-30 °, 45 ° noma ama-90 ° angle ngokusho kwamakhasimende asetshenziswayo, ama-angle amabili angama-45 ° angangena ku-90 ° angle ngokuphelele.