Ukulimala kwemisebe ye-laser emzimbeni womuntu kudalwa yimiphumela ye-laser thermal, umphumela wengcindezi ye-loight Kunamabanga amane, i-laser esetshenziswa emshinini we-fiber laser cutting ngowaseClass IV. Ngakho-ke, ukwenza ngcono izinga lokuvikela umshini akuyona nje kuphela indlela yokuvikela ephumelela ngayo bonke abasebenzi abadinga ukufinyelela kulolu hlobo lwemishini, kodwa futhi banesibopho sokusebenzisa abasebenzi abasebenza lo mshini. Manje amandla we-laser we-fiber laser ukusika umshini wokusika aya ngokuya ephakeme futhi ephakeme, kusukela ekuqaleni komshini wokusika we-500w we-laser kuya ku-15000W amandla omshini wokusika, ukukhula ngokushesha kwamandla we-laser kwenza ukuvikeleka kwe-laser kubaluleke kakhulu.

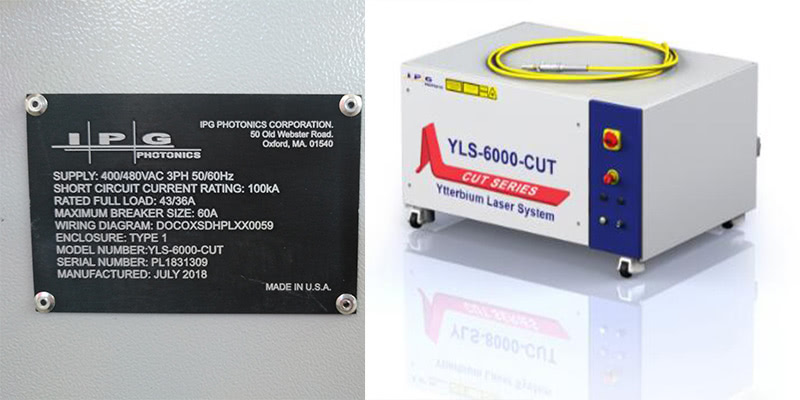

I-6000W IPG laser Source

Yasungulwa ngo-1992, i-Laser yeGolide yayihlala igxile ekukhiqizeni komshini we-laser, futhi ihlanganiswe design ye-laser yomkhiqizo, ukukhiqiza, ukuthengisa kanye nensizakalo.Inqolobane yomkhiqizo wokuqala, umqondo wokuphepha okokuqala wajova. Le khasiKuvalwe ngokugcwele umshini we-pallet table ye-laseryethulwe kulo mqondo.

Izithombe ezinhle kakhulu zomshini wokusika we-fiber laser

I-1.Lull Evinjelwe Idizayini iqinisekisa ukubonwa ngokuphepha kwenqubo yokusika

Njengoba ubona esithombeni esingenhla, uphephile ngokuphelele uma ume ngaphambi kwalo mshini we-pallet table we-pallet we-laser cutting.I-Design ebiyelwe ngokuphelele ivumela wonke ama-lasers abonakalayo endaweni ebiyelwe. Ngaleso sikhathi, ukuze ubheke amandla okusika ama-laser ngesikhathi sangempela, iWindows ebonakalayo yenzelwe ngaphambili kanye nohlangothi lomshini. Iwindi lokubonana lisebenzisa izindinganiso eziphakeme kakhulu ze-radiations glass, futhi iwindi likhulu ngokwanele ukuthi ubone inqubo yokusika. Noma ungenazo izingilazi zokuphepha ze-laser, ungabamba ngokuphephile "ubuhle bokusika" be-laser.

Umshini wokusika we-fiber laser ngethebula lokushintshana kwePallet

Ikhamera yencazelo ye-2.Isinesincazelo iqapha ukucubungula kokusika ngesikhathi sangempela

Idizayini yesibili egqamile yalo mshini ukuthi sifake ikhamera enencazelo ephezulu nge-angle efanelekile ngaphakathi kwendawo ebiyelwe ukuze uqiniseke ukuthi opharetha angabona inqubo yokusika i-laser ngokucacile ngenkathi esebenza umshini. Ngaleso sikhathi, ikhamera izokwethula isikrini sokuqapha esicacile nesibambezeli etafuleni lokusebenza, ngakho-ke opharetha angawazi ngomshini ngaphakathi noma ngabe esebenza lo mshini. Uma imishini inezimo ezingejwayelekile, opharetha futhi angayiphatha ngempumelelo okokuqala ukugwema okunye ukulahleka.

Uhlelo lokupholisa umoya ophezulu ngothuli kanye neqoqo le-smog

Uhlelo lwe-3.Machine Top Lovertion lwenza kube ukuvikelwa kwezemvelo

Ngesikhathi senqubo yokusika i-laser, ikakhulukazi lapho usika insimbi yekhabhoni nensimbi engenacala, kuzokhiqiza intuthu eqinile nothuli. Uma kungenzeki ukuqeda ngempumelelo le ntuthu nothuli ngesikhathi, inani elikhulu lentuthu elibuthelwa ngaphakathi komshini lizodala indawo yokungaboni kahle lapho ubhekisisa khona. Kulokhu, besikucabangele ukwakhiwa komshini. Uthuli lokusika nentuthu kushaywa yigesi ekusikeni, ngakho-ke kuzosakazeka ngamafomu nezinkomba ezahlukahlukene, kepha iningi lazo lizogxila maphakathi nomshini. Ngokusho kokunyakaza nokugeleza kwentuthu, umshini waklanywa ngohlelo oluphezulu lwengxenye yothuli. Izimbobo eziqoqiwe zothuli zisatshalaliswa ngaphezulu komshini phezulu ngamawindi amaningi kanye nokusatshalaliswa, futhi umshini uhlome nge-turbine enkulu yomoya. Ngakho-ke, ekusetshenzisweni kwangempela, umphumela wokuqoqa uthuli muhle kakhulu.

Uma usuyiqonda kahle umshini we-pallet table we-pallet we-laser yokusika, kufanele ukwazi ukuqonda ukuthi kungakusiza ukudala inani ngokuphepha ngenkathi ulisebenzisa ukwenza ngcono ukukhiqizwa kanye nokusebenza kahle komnotho.