Isakhiwo Esihlanganisiwe Esigcwele

1. Idizayini yangempela Egcwele Egcwele yesakhiwo yenza sengathi yonke i-laser ebonakalayo endaweni yokusebenza yemishini ngaphakathi, ukunciphisa ukulimala kwemisebe ye-laser, futhi inikeze isivikelo esiphephile sendawo yokucubungula yomqhubi;

2. Ngesikhathi senqubo yokusika i-laser yensimbi, ikhiqiza intuthu yothuli oluningi. Ngesakhiwo esivaliwe esigcwele kangaka, kuqinisekisa ukuhlukaniswa okuhle konke uthuli oluvela ngaphandle. Maqondana nomgomo wokugeleza okuguquguqukayo kothuli lwentuthu eshisayo, samukela umklamo wephampu osabalalisiwe ophahleni esikhundleni somklamo wepompo ophansi. Ngaleso sikhathi, sithuthukise abalandeli abakhulu abanamandla ukuze basebenze, sihlose ukunciphisa ukungcoliswa kothuli, ukugcina indawo yokusebenza ihlanzekile futhi inobungane futhi sivikele impilo yomsebenzisi esikhathini eside.

Ithebula Lokulawula

1. Lahla iplathifomu yokusebenza eshumekiwe yegobolondo lemishini yendabuko, isebenzisa inkundla yokulawula ejikelezayo yangaphandle, igcine ubuqotho bokubukeka kwayo yonke into, ihlinzekele izindinganiso zokuklama zezimboni zemishini ye-CNC ephezulu.

2. Ikhonsoli izungeza ngobukhulu obuthathu ku-Angle engu-270 degree ukuze isekele ukusebenza kwe-multi-dimensional

3. Iwindi lokuqapha, isikhombimsebenzisi sokusebenza, iphaneli yokulawula izinombolo eziphezulu, igundane elingenantambo kanye nekhibhodi kuhlanganiswe etafuleni lokusebenza. I interface efanayo eyodwa kuphela engabonakala ngokuvula nokuvala umshini , noma uqale kabusha esimweni sokulinda sokulinda .

4. Idivayisi ifakwe ikhamera yokuqapha ephezulu, ukuboniswa okuguquguqukayo kwesikhathi sangempela senqubo yonke ye-laser cutting.Ukusebenza kwemishini kanye nokuqapha isimo sokusebenza komshini kungacatshangelwa ngesikhathi esifanayo.

5. Idivayisi ifakwe ikhamera yokuqapha ephezulu, ukuboniswa okuguquguqukayo kwesikhathi sangempela sayo yonke inqubo ye-laser cutting.Ukusebenza kwemishini kanye nokuqapha isimo sokusebenza komshini kungacatshangelwa ngesikhathi esifanayo.

Isoftware

Umnciphisi

I-Golden Vtop isebenzisa i-nLIGHT laser Generator-High reflesive metal cutting capacity

I-laser ye-nLIGHT inenzuzo ekusebenzeni kokusika kwezinto zensimbi ezibonisa ukukhanya okuphezulu, ukufeza ukucubungula okuvamile kwe-aluminium, ithusi, ithusi, igolide nesiliva njll, kuyilapho inokusebenza okuvelele kokusika kwe-carbon steel evamile nensimbi engagqwali futhi.

I-laser ye-NLIGHT - ivimbela ukufiphala

Ngomklamo wokuvala ojwayelekile we-NEMA 12, wonke amamojula ane-CDA yokuhlanza igesi esibonakalayo. Inzwa yomswakama eyakhelwe ngaphakathi kanye nedivayisi yokukhiya yangaphakathi, okungaba lula ukuhlanganisa kumishini.Ukufaka okuqhubekayo komoya ocindezelayo ophansi ngaphakathi kwe-laser okungaqinisekisa ukuthi i-laser ihlale isendaweni eyomile. Ukunciphisa umthelela wezinga lokushisa lendawo yangaphandle kanye nomswakama ku-laser ube ubuncane. Ngaleso sikhathi, umthombo we-laser wangaphakathi ugcwele umoya, ukwenza ingcindezi kancane kancane, bese wenza ungqimba oluvikelayo lwe-laser barrier yangaphandle, lapho uthuli lungena ngaphakathi, lungagcina i-laser ihlanzekile ngaphakathi. Le miklamo emisha enjalo yomthombo we-Nlight yelule kakhulu isikhathi sokuphila kwe-laser.Ngakho, i-laser ingahlonywa ngokuhlukile ngesipholile somoya, ukuze igcine izinga lokushisa eliqinile le-stbale futhi ivimbele ukufiphala kahle . Ngakho-ke, i-nLIGHT laser inale nzuzo eyingqayizivele ekubekezeleleni okuqinile esimweni esibi sendawo.

I-NLIGHT laser - amamojula awawonakali kalula

I-NLIGHT laser - amamojula awawonakali kalula

1. Ngokulandela umkhondo wokusetshenziswa kwemishini yekhasimende eminyakeni yamuva, ukuhlaziya kwezibalo kwedatha yezinga lokuhluleka kwe-laser kubonisa ukuthi izinga lokuhluleka kwe-laser ye-nLIGHT liphansi kakhulu kunezinye izinhlobo, izinga lomonakalo wemojuli cishe liqanda, futhi lihlala liwukusebenza okuzinzile kwesikhathi eside. Ithole amakhasimende amaningi amasha namadala umusa nokwethenjwa, , esusa ukungabaza kwelaser ye-nLIGHT esigabeni sokuqala, futhi inamathele ukukhetha uhlobo lwe-nLIGHT ngemuva kokuyisebenzisa.

2. Futhi kwezinye izinhlobo ze-laser .ngemuva kokusebenzisa isikhathi, ikakhulukazi ngemva kwesikhathi esingaphezu kwewaranti, Izinga lokulimala kwe-module ye-laser yangaphakathi liphezulu kakhulu futhi ngokuvamile , elibangelwa i-odensation noma ezinye izinkinga. Ukushintsha inani lemojula entsha liphezulu kakhulu, isikhathi somjikelezo side.ikhasimende lilahlekelwe okukhulayo ngale nkinga.

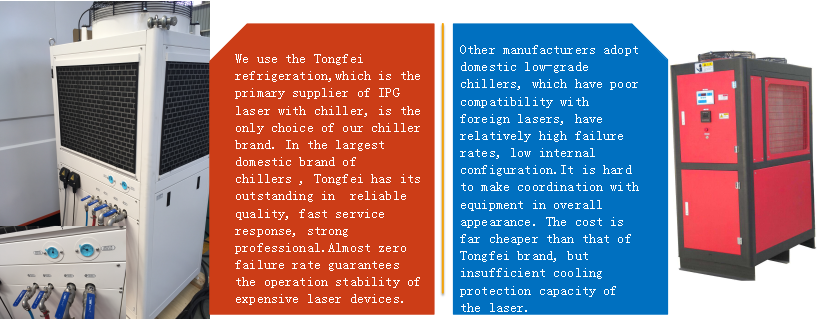

I-Chiller yamanzi

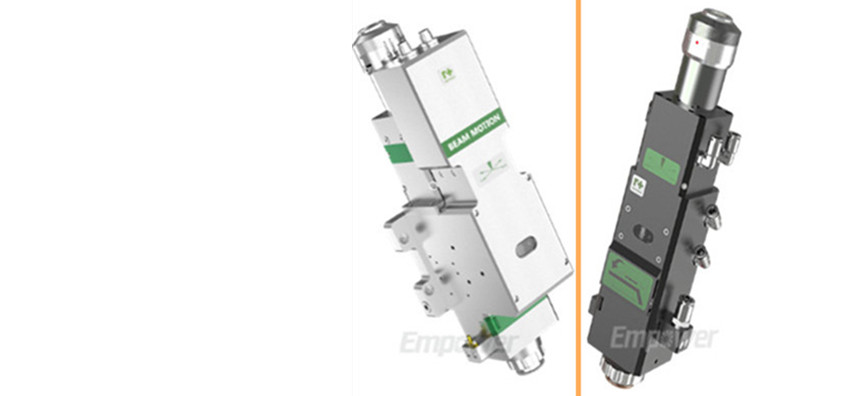

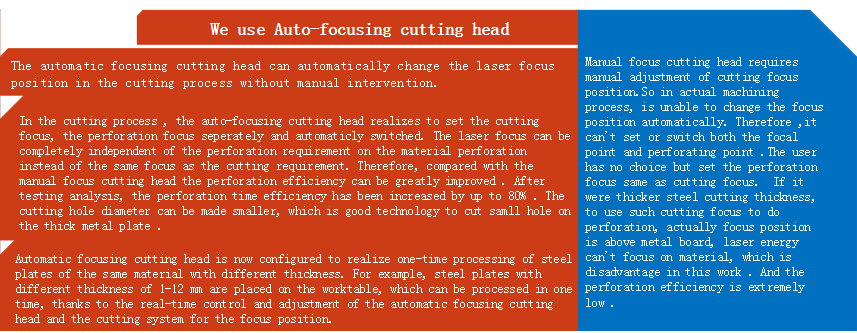

Ikhanda lokusika eligxile ngokuzenzakalela

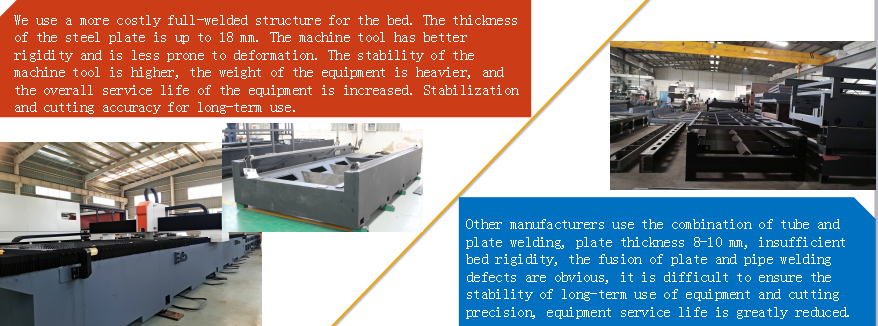

Umzimba Womshini Oshiselwe

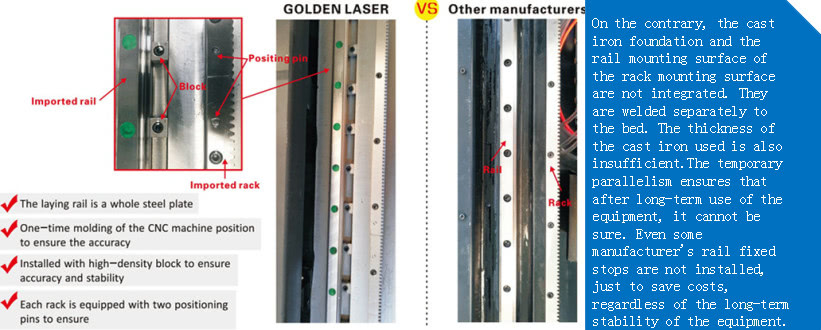

Indawo yokufaka ujantshi we-rack guide

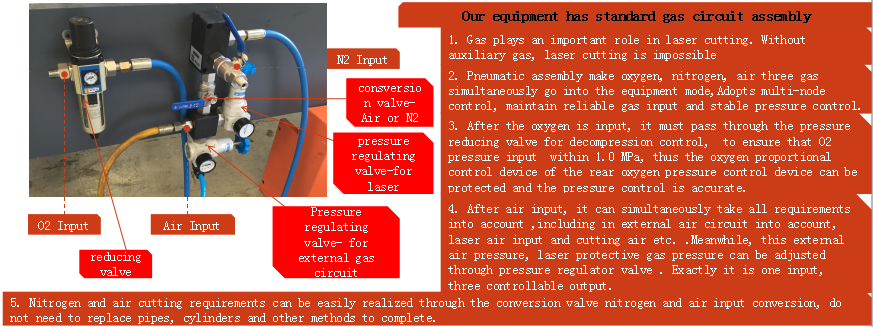

I-Gas Circuit

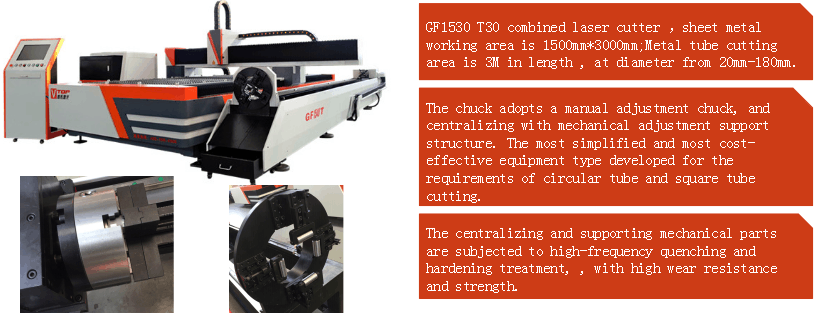

Ishidi Lensimbi Kanye Neshubhu Edidiyelwe Umshini Wokusika weLaser -3 m ukusika ishubhu

Uchungechunge lwe-GF-T

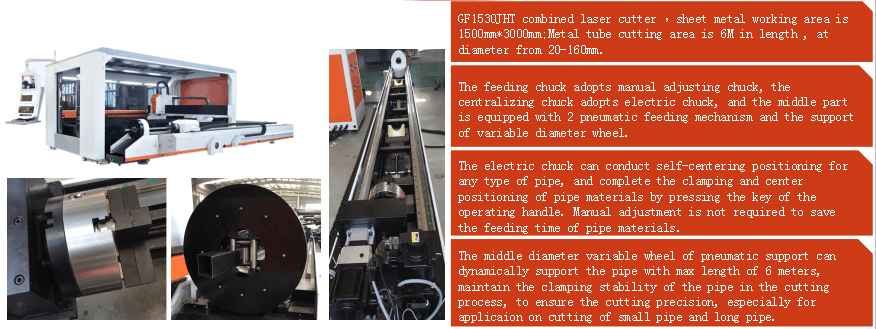

I-GF-1530JHT

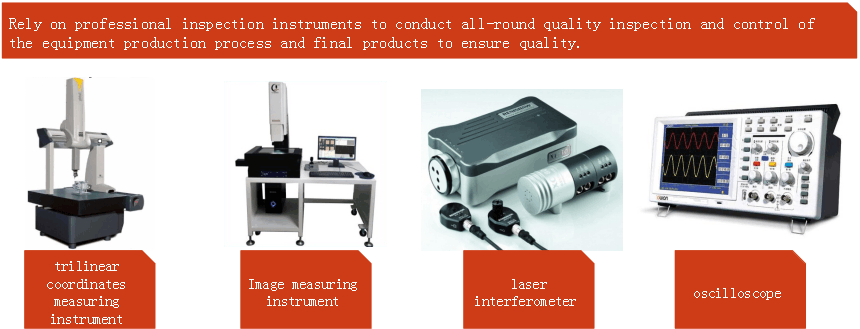

Izingxenyekazi zekhompuyutha zokuhlola i-QC

Imibiko yokuhlolwa komshini

Ividiyo yedemo yomshini we-GF-JH

Ividiyo yedemo yomshini we-GF-JHT