Ingabe ukhathazekile ukuthi ikhwalithi yokusika i-laser emikhiqizweni eqediwe ayikwazi ukusetshenziswa ngenxa yokukhubazeka okuhlukahlukene epayipi ngokwayo, njengokuguqulwa, ukugoba, njll.?

Kuhlelo lokudayisaimishini yokusika ipayipi ye-laser, amanye amakhasimende akhathazeke kakhulu ngale nkinga, ngoba uma uthenga inqwaba yamapayipi, kuzohlala kunekhwalithi engalingani noma engaphansi, futhi ungakwazi't lahla wisikhukhukazi la mapayipi alahlwa, indlela yokuthuthukisa izinga lokusebenzisa amapayipi kanye nokunciphisa izinga le-scrap kuyinkinga umshini wethu wokusika ipayipi le-laser okufanele uyixazulule.

Ngakho-ke, namuhla sizokhuluma ngendlela yokuqedela ukusika kwe-laser kwekhwalithi ephezulu yamapayipi akhubazekile.

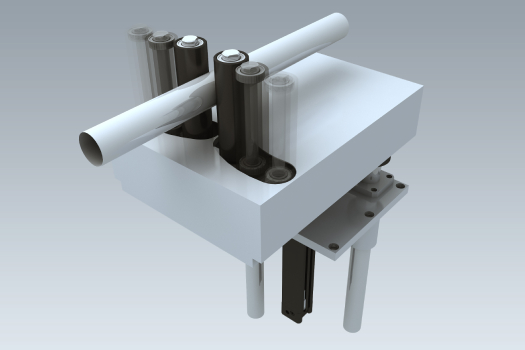

1. Ingxenye yokondla ipayipi, okungukuthi, idivaysi e-othomathikhi ye-centering yengezwe ngaphambi kokusika kwe-laser, engakwazi ukubona ukulungiswa ngokomzimba kwamapayipi amancane namapayipi ane-deformation encane, okungukuthi, ukulungiswa ngaphambi kokusika ukuze kuqhutshekwe nokunciphisa ukuguquguquka kwepayipi ngokwayo. Lokhu kuholela ekuwohlokeni kokusika kwe-laser.

2. Ukusebenzisa i-capacitive sensing fibre laser cutting head ukuze kuzuzwe ukunemba okuphezulu, ukuzwela okuphezulu, nokusika kokuzinza okuphezulu.

3. Phakathi nenqubo yokusika, ekuphenduleni izidingo zokucubungula amapayipi amise okukhethekile, njengamapayipi amise okweqanda, amapayipi e-DR, namanye amapayipi akhethekile, sithuthukise ubuchwepheshe bokusika i-laser kumapayipi akhethekile ahlukene, ubuchwepheshe bokunxeshezelwa okuzenzakalelayo bokuhlanekezelwa kwamapayipi, kanye nokuguqulwa kokugoba, okungaxazulula inkinga yepayipi ngokwayo. Isizathu yisici sokusika kwe-laser.

4. Ngensimbi engagqwali, ingxubevange ye-aluminium, namanye amapayipi engxubevange okushisa aphezulu, ngokusebenzisa ubuchwepheshe obukhethekile bokulawula kanye nobuchwepheshe bokwelapha ekhoneni, ungakhetha imigqa ehlukene yokuhola, i-corn-turn pulse cutting control, kanye nemisebenzi yokucubungula ekhoneni ngokusho kwezici zepayipi le-alloy elishisa kakhulu ngesikhathi sokuncibilika nokusika ukunciphisa ama-chips. ilensi, futhi ithuthukisa impilo yesevisi yelensi yokugxila.

5. Lapho usika amakhona abukhali, usebenzisa amandla e-laser ahlukene, imvamisa yokushaya kwenhliziyo, nomjikelezo womsebenzi we-pulse kungaqinisekisa ikhwalithi yekhonta elicijile lokusika futhi kuthuthukise ukusebenza kahle kokusika.

Ukufingqa, ukuqinisekisa umphumela wokusika wamapayipi abonakele, sihlanganise i-R&D kanye nokuthuthukiswa kusuka ekwakhiweni kwemishini, ikhanda lokusika i-laser kuya kusoftware yokusika i-laser, okuthuthukisa kakhulu ukunemba okuphezulu kanye nesivinini esikhulu sokusika ipayipi.

Yiziphi ezinye izinto ozikhathazayo ekusikeni amapayipi? Siyakwamukela ukuthi usitshele nge-imeyili, futhi sizokusiza ukuxazulula izinkinga zakho ngokushesha okukhulu.