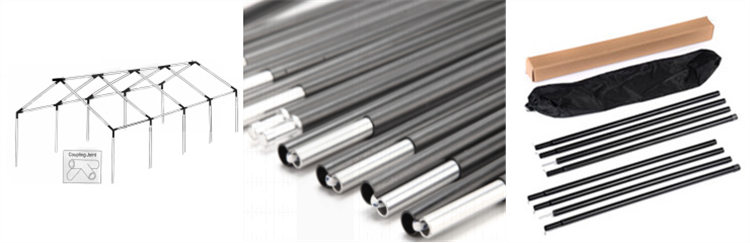

Amatende aqinile athatha amafomu ohlaka, aqukethe i-stent yensimbi, i-canvas kanye neseyili. Lolu hlobo lwetende luhle ekufakeni umsindo, futhi ngokuqina okuhle, ukuzinza okuqinile, ukugcinwa kokushisa, ukubumba okusheshayo nokululama. Ama-stents asekela itende, ngokuvamile ayenziwa ngensimbi yengilazi ne-aluminium alloy, ubude be-stent busuka ku-25cm kuya ku-45cm, kanti ububanzi bembobo yesigxobo bungu-7mm kuya ku-12mm.

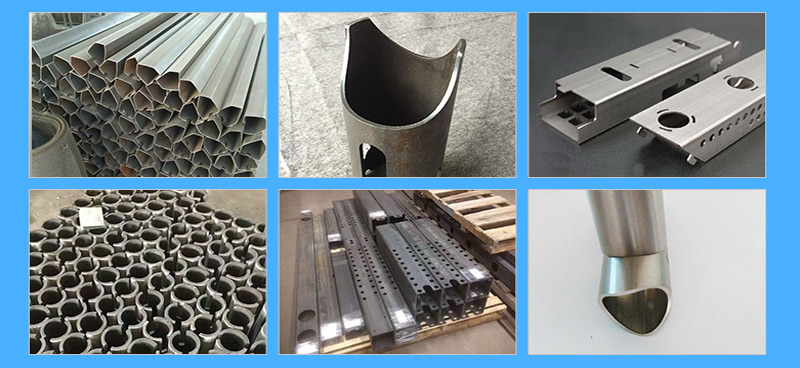

Muva nje, sithole ikhasimende ebelisebenzela ukukhiqiza amatende ngaphandle, livakashele imboni yethu. Kusuka kukhasimende, sasazi ukuthi ukukhiqizwa kwetende le-stent kudinga izinqubo eziningi, njengokusaha ipayipi, ukucutshungulwa kwe-lathe, izimbobo zokubhoboza nokubhoboza, ukushisela i-TIG yepayipi njll.

Okokuqala, idinga umshini wokusaha wokunqanyulwa kwepayipi, ukusika kufanele kuhambisane nomdwebo futhi kudinga ukususa ama-burrs abukhali ngesandla.

Okwesibili, ihambisana nokucutshungulwa kwe-lathe yokusika i-chamfer kanye nokukhipha izimbobo zangaphakathi noma zangaphandle.

Okwesithathu, ngemuva kokusika, idinga umshini wokubhoboza nokubhoboza wezimbobo zokubhoboza nokubhoboza njll.

Okwesine, ipayipi lalidinga ukushiselwa ndawonye, futhi isitshalo sidinga ilebula yokunamathisela ukuze siphawule wonke amapayipi ngokulandelana kwawo.

Ngemuva kwazo zonke lezi zinqubo imboni ithola i-stent. Kodwa idinga amasethi amaningi okusaha, ukubhoboza, imishini yokumba, kodwa futhi idinga abasebenzi abaningi kakhulu.

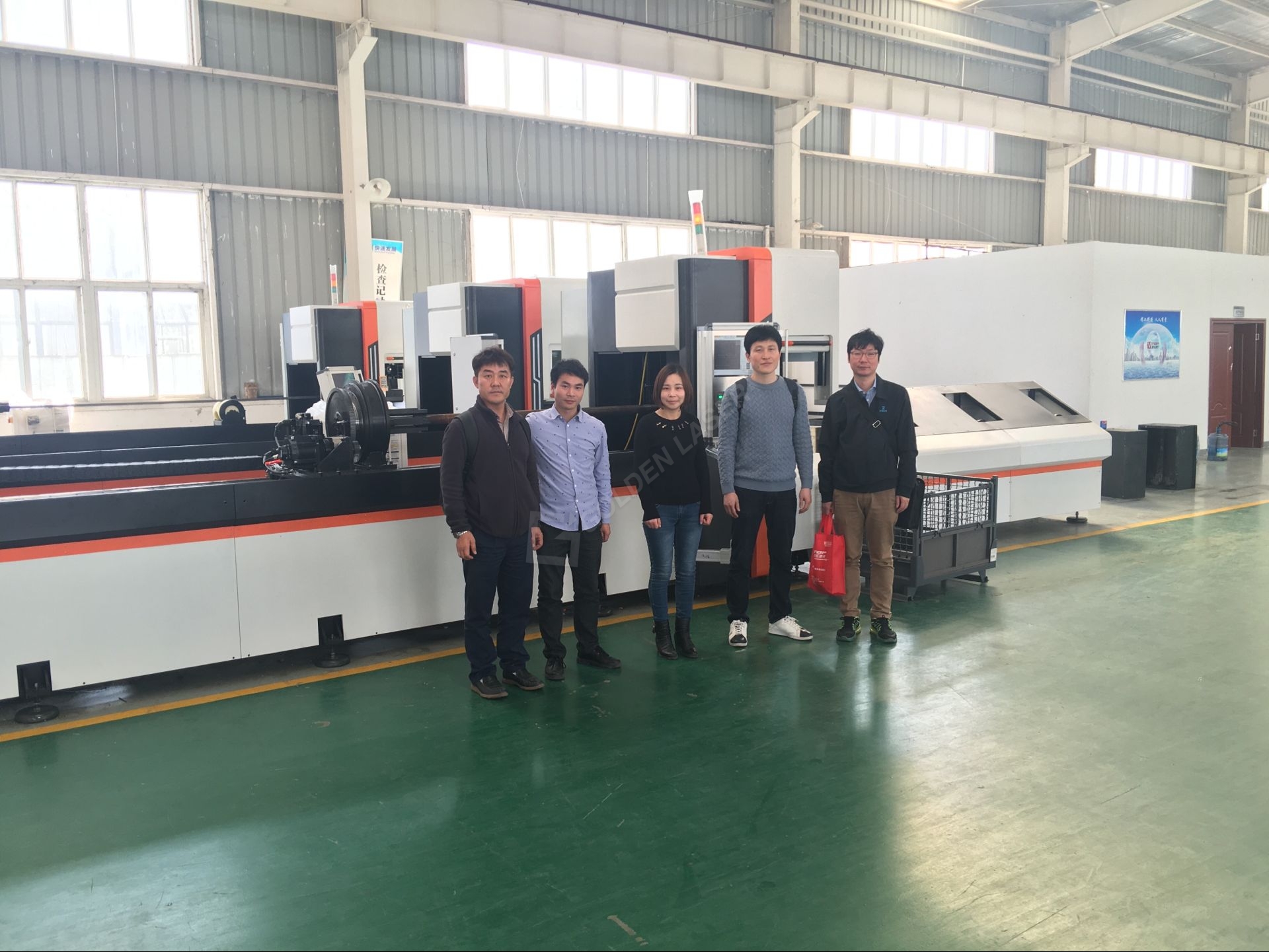

Ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza nokuzivumelanisa nezimfuneko zokukhiqiza zesimanje, ikhasimende lenze ucwaningo oluningi lwemakethe, ekugcineni lathinta i-laser yegolide futhi lifuna ukwethula umshini wokushisela we-GOLDEN-VTOP LASER.

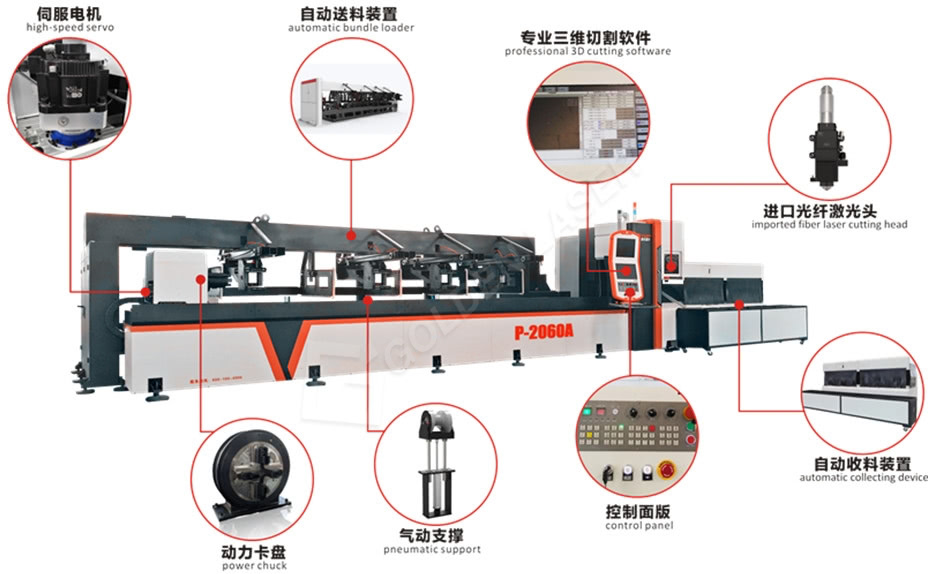

I-Golden Vtop laser pipe laser cutting machine ilungele zonke izinhlobo zokusika ishubhu noma ipayipi, ingacubungula ipayipi noma ubude beshubhu obuyi-6m, 8m no-12m, nobubanzi buka-10-300mm. Manje isetshenziswe ngempumelelo ezimbonini ezifana nokucutshungulwa kwamapayipi, imishini yokufaneleka, ifenisha yensimbi, i-chassis yemoto, i-showcase kanye neshalofu, ukwakhiwa njll. Umshini wokusika we-laser we-laser wegolide we-laser uhlanganiswe nesistimu ye-automatic bundle loader, ngakho-ke ayidingi isisebenzi ukulayisha amapayipi.

Futhi inezinzuzo ezilandelayo:

1. Yonga indawo yokusebenza nendawo yaphansi

Ngoba umshini wokusika ipayipi we-laser unganciphisa imishini ye-punch engu-3-4, imishini yokubhoboza engu-1-2, imishini yokusaha eyi-1-2. Ngakho-ke isindisa indawo yaphansi yama-workshops angu-1-2 kanye nezindleko zabantu mayelana nabantu abangu-7. Yehlisa isinyathelo sokucubungula futhi wonge isikhathi.

Umshini wokusika ipayipi we-laser ungafinyelela ukumaka okuzenzakalelayo, ukusika kwe-CNC nokwenza ngesikhathi esisodwa, ifanele zonke izinhlobo zepayipi kanye nezidingo zokusika (ukusika, ukugoqa, ukusika, ukubhoboza, ukusika izimbali), futhi indawo yokuphela kokusika ipholile ngaphandle kokukhipha futhi i-black-edged.

2. Okonga izinto

Umsiki we-laser wepayipi angakwazi ukubala ngokuzenzakalelayo ukwakheka nezindlela zokusika, cishe kungabikho udoti. Akukho ukuxhumana okuqondile phakathi kwekhanda lokusika kanye nodonga lwamapayipi, ngakho-ke indawo yokugcina yokusika ibushelelezi futhi ingenawo ama-black-edged, akukho deformation yemikhiqizo eqediwe futhi cishe akukho ukulahlekelwa.

3. Ukunemba okuphezulu

I-laser yegolide yepayipi le-laser cutter ingafuna ngokuzenzakalelayo umphetho futhi yenze ukulungiswa, ngisho nokusika okuqhubekayo kwesikhathi eside, kusaqinisekisa ukunemba nokuvumelana komkhiqizo ophelile. I-chuck ingalungiswa ngokuzenzakalelayo futhi ifakwe, ngokulayishwa ngokuzenzakalela, iqeda umthelela wokwenziwa kumkhiqizo oqediwe.