1. Yini ishidi le-silicon?

Amashidi ensimbi we-silicon asetshenziswa ngogesi ajwayelewa njengamashidi ensimbi we-silicon. Kuluhlobo lweFerrosilicon Soft Magnetic alloy efaka ikhabhoni ephansi kakhulu. Ngokuvamile iqukethe i-silicon engu-0.5-4.5% futhi idonswe ngokushisa nokubanda. Ngokuvamile, ubukhulu bungaphansi kwe-1 mm, ngakho-ke ibizwa ngokuthi yipuleti elincanyana. Ukungezwa kwe-silicon kwandisa ukumelana kukagesi kwensimbi kanye nokuvumela okuphezulu kwamandla kazibuthe, ukunciphisa ukuxhumeka, ukulahleka okuyisisekelo (ukulahleka kwensimbi) kanye nokuguga kwamandla kazibuthe.

Ishidi le-silicon lisetshenziselwa ikakhulukazi ukwenza ama-iron cores wabathengisi abahlukahlukene, ama-motors kanye nama-generator.

Lolu hlobo lweshidi lensimbi ye-silicon linezakhiwo ezinhle kakhulu ze-elekthronigagnetic, yizinto ezibaluleke kakhulu nezibalulekile ze-kazibuthe kumandla, ukuxhumana ngocingo kanye nezimboni zezinsimbi.

2. Izici zeshidi le-silicon

A. Ukulahleka kwensimbi okuphansi kuyinkomba ebaluleke kakhulu yekhwalithi. Wonke amazwe aseMhlabeni ahlukanisa ukulahleka kwensimbi njengebanga, ukwehlisa ukulahleka kwensimbi, ukukhuphuka ibanga, kanye nekhwalithi engcono.

B. Ukungeniswa kwamandla kazibuthe okuphezulu. Ngaphansi komkha kazibuthe ofanayo, ishidi le-silicon lithola ukuthambeka okuphezulu kwamandla. Ivolumu nesisindo semoto kanye ne-transformer iron core ekhiqizwa yi-silicon sheet incane futhi ilula, ngakho-ke kungagcina izinto zokwakha zethusi, ezifaka ngaphansi.

C.Higger Stacking. Ngaphezulu okubushelelezi, isicaba kanye nobukhulu obulinganayo, ishidi lensimbi le-silicon lingatataka phezulu kakhulu.

D.Umugqa omuhle unama-adhesion amahle kwifilimu efaka ukufakwa futhi kulula ukufudumala.

I-3. Isidingo Sokukhiqiza Insimbi Yesilo

Ubukhulu bezinto ezibonakalayo: ≤1.0mm; okujwayelekile 0.35mm 0.5mm 0.65mm;

➢ Izinto ezibonakalayo: Ferrosilicon Alloy

➢ Izidingo zemidwebo: Kuvaliwe noma akuvaliwe;

➢ Izidingo Zokunemba: Ibanga 8 kuya ku-10;

➢ Imfuneko yokuphakama kwe-Glitch: ≤0.03mm;

4. Inqubo yokukhiqiza yensimbi ye-silicon

➢ Ukugunda: Ukugunda kuyindlela yokusebenzisa umshini wokugunda noma isikhafu. Ukwakheka kwe-WorkPees ngokuvamile kulula kakhulu.

➢ Ukubhoboza: Ukubhoboza kubhekisele ekusetshenzisweni kwezikhunta zokubhoboza, ukusika izimbobo njll Futhi ingaklama isikhunta ukubhonca zonke izinhlobo ze-silicon yensimbi.

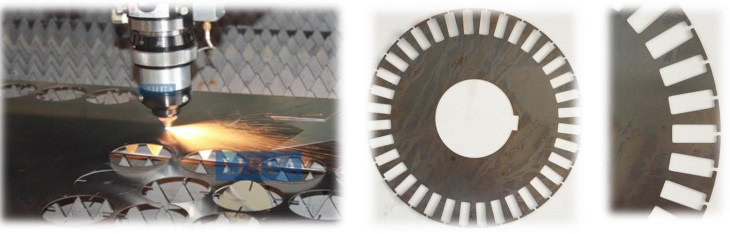

Ukusika: Kusetshenziswa umshini wokusika we-laser ukusika zonke izinhlobo zomsebenzi. Futhi yiba yindawo evamile yokusika yokucubungula i-Silico Sheet.

➢ Qina: Njengoba i-Iron chip Burr ithinta ngqo ukusebenza kwe-Transformer, ngakho-ke uma ukuphakama kwe-burr kuphakeme kune-0.03mm, kudinga ukuchotshozwa ngaphambi kokupenda.

Ukupenda: Ingaphezulu le-Iron chip lizopendwe ngefilimu eqinile, engamelana nokushisa nokugqwala kwefilimu.

Ukomisa: Upende weshidi lensimbi le-silicon kufanele womiswe emazingeni okushisa athile bese uphuca amandla aqinile, aqinile, aphezulu we-dielectric film.

I-5. Ukuqhathanisa kwenqubo - Ukusika kwe-laser

Ukusika kwe-laser: okuqukethwe kubekwe etafuleni lomshini, futhi kuzosika ngohlelo lokusethwa noma isithombe. Ukusika kwe-laser inqubo eshisayo.

Izinzuzo ze-Laser inqubo:

➢ Ukuguquguquka okuphezulu, ungahlela imisebenzi yokucubungula nganoma yisiphi isikhathi;

➢ Ukucaciswa okuphezulu okuphezulu, ukucaciswa komshini ojwayelekile kungukuqamba okungu-0.01mm, kanye nokunemba kokunciphisa i-laser kungu-0.02mm;

Ukungenelela okungaphansi kwesandla, udinga kuphela ukubeka izinqubo kanye namapharamitha enqubo, bese uqala ukucubungula ngenkinobho eyodwa;

➢ Ukungcoliswa komsindo okusebenzayo akunakwa;

➢ Imikhiqizo eqediwe ayinazo ama-burrs;

➢ Ukusebenza kokusebenza kungaba lula, kuyinkimbinkimbi futhi kunesikhala sokusebenza okungenamkhawulo;

➢ Umshini wokusika we-laser uwukulungiswa kwamahhala;

➢ Kusetshenziswa izindleko eziphansi;

➢ Izinto zokonga, ungasebenzisa umsebenzi wokwabelana ngonqenqema ngesoftware edliwe ukufezekisa ilungiselelo elifanele lomsebenzi, futhi wandise ukusetshenziswa kwezinto ezibonakalayo.

6. Izisombululo zokusika ze-Laser

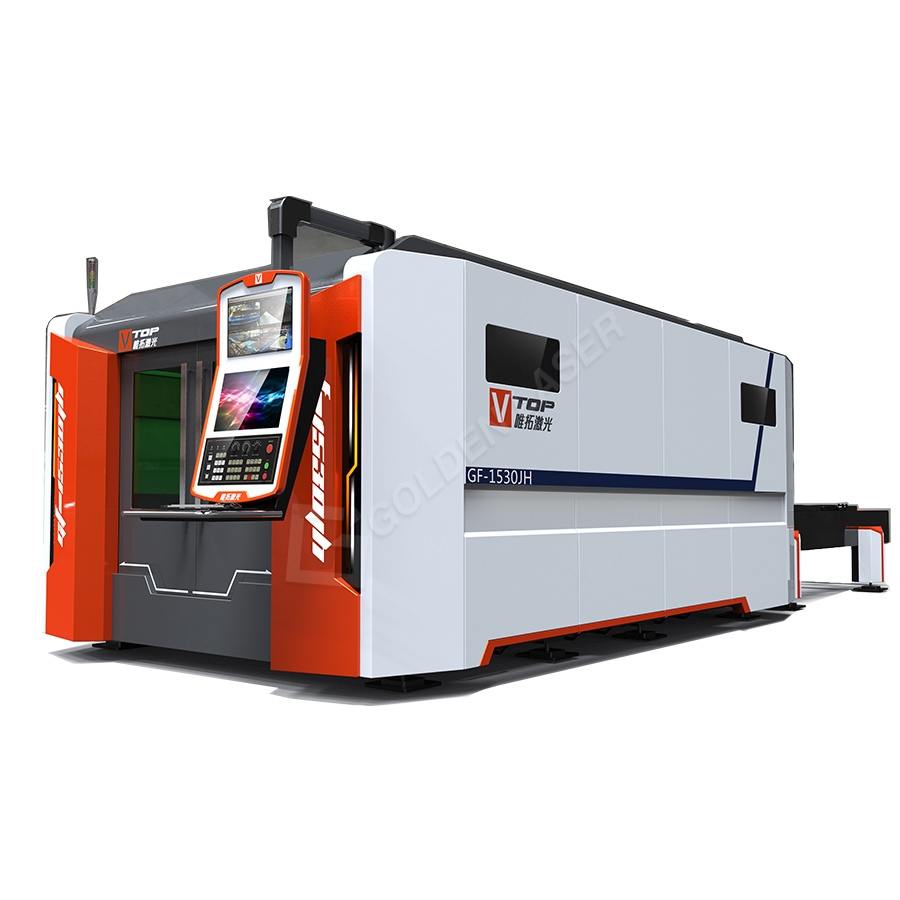

Uhlobo oluvulekile lwe-1530 Fiber Laser Cutter GF-1530 Ukucaca okuphezulu kwe-Laser Cutter GF-6060 okuvalekile okuvalekile kwetafula le-Laser Cutter GF-1530JH