Imisebenzi yokukhiqiza ye-Laser njengamanje ifaka ukusika, ukushisela ukushisa, ukukhwabanisa, ukungcola, ukufakwa kwemvelo, okuqoshwe, ukubhala, ukubhebhana, nokuqina nokuqina kokuqina. Izinqubo zokukhiqiza ze-Laser zincintisana zombili ubuchwepheshe nangokomnotho ngezinqubo zokukhiqiza ezijwayelekile nezingezinhle ezifana nemishini yokukhiqiza kanye ne-arc, i-ElectChemical, kanye nokusika kwamanzi, ukusika kwe-Jet kanye nokusika kwamalangabi.

Ukusika kwamanzi kwe-jet kuyinqubo esetshenziselwa ukusika izinto ezisebenzisa i-jet yamanzi acindezelwe njengamakhilogremu angama-60 000 nge-inch (PSI). Imvamisa, amanzi ahlanganiswa ne-rudive efana ne-garnet evumela izinto eziningi ukuze zinqunywe ngokuvalwa ukuze zivale ukubekezelela ukubekezelelana, okubucayi nangonqenqemeni oluhle. Ama-Jets wamanzi ayakwazi ukusika izinto eziningi zezimboni kufaka phakathi insimbi engenasici, infoldel, titanium, i-aluminium, ithuluzi lensimbi, i-ceramics, i-granite, nepuleti yezembatho. Le nqubo yakha umsindo obalulekile.

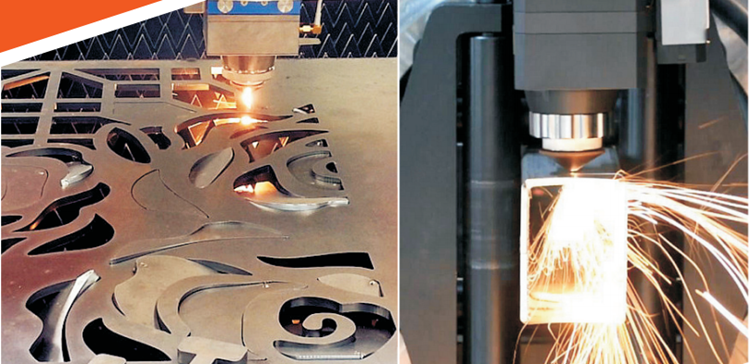

Ithebula elilandelayo liqukethe ukuqhathanisa nokusika insimbi kusetshenziswa inqubo ye-CO2 laser yokusika kanye nenqubo yokusika amanzi e-Jet ekusebenzeni kwezinto ezibonakalayo.

§ Ukwehluka Kwenqubo Okuyisisekelo

§ Izicelo Ejwayelekile Zenqubo nokusebenzisa

§ Ukutshalwa kwemali kokuqala kanye nezindleko ezisebenzayo zokusebenza

§ Ukucacisa inqubo

§ Ukucatshangelwa Kwezokuphepha Nendawo Yokusebenza

Ukwehluka Kwenqubo Okuyisisekelo

| Beka | I-CO2 laser | Ukusika kwamanzi amanzi |

| Indlela yokudlulisa amandla | I-Light 10.6 M (Uhla lwe-Infrared Infrared) | Nisela |

| Umthombo wamandla | Igesi Laser | Iphampu ephezulu yokucindezela |

| Amandla adluliselwa ngayo | UBeam uqondiswe izibuko (ezindizayo ze-Optics); ukudluliswa kwefayiji hhayi Ingenzeka ku-Co2 laser | Ama-hoses aqinile we-High-Pressures adlulisela amandla |

| Indlela enqunywe kanjani ixoshwa | Igesi Jet, kanye nezinye igesi eyengeziwe ethengisa izinto ezibonakalayo | I-jet yamanzi ephezulu kakhulu ikhipha imfucuza |

| Ibanga phakathi kwe-nozzle kanye nokubonakalayo nokubekezelela okuphezulu okuvumayo | Cishe u-0.2 "0.004", inzwa yebanga, umthetho kanye ne-z-axis edingekayo | Cishe u-0.12 "0.04", inzwa yebanga, umthethonqubo kanye ne-z-axis edingekayo |

| Umshini Womzimba Usethi | Umthombo we-laser uhlala etholakala emshinini yangaphakathi | Indawo esebenzayo nephampu kungatholakala ngokwahlukana |

| Uhla lwamasayizi wethebula | 8 'x 4' kuya ku-20 'x 6.5' | 8 'x 4' kuya ku-13 'x 6.5' |

| Ukukhishwa okujwayelekile kwe-beam endaweni yokusebenza | 1500 kuya ku-2600 Watts | 4 kuya ku-17 kilowatts (4000 bar) |

Izicelo zenqubo ezijwayelekile nokusebenzisa

| Beka | I-CO2 laser | Ukusika kwamanzi amanzi |

| Inqubo ejwayelekile isebenzisa | Ukusika, ukumba, ukubhala, ukuhlukunyezwa, ukuhleleka, ukushisela | Ukusika, ukuhlukunyezwa, ukuhlelwa |

| Ukusika okubonakalayo kwe-3D | Kunzima ngenxa yokuqondisa okuqinile kwe-beam kanye nokulawulwa kwebanga | Ngokuhlukahluka njengoba amandla asele ngemuva komsebenzi abhujisiwe |

| Izinto zokwakha ezikwazi ukusikwa yinqubo | Zonke izinsimbi (ngaphandle kwezinsimbi ezibonisa kakhulu), wonke amapulasitiki, ingilazi kanye nokhuni kungagawulwa | Zonke izinto zokwakha zinganqunywa yile nqubo |

| Inhlanganisela yezinto ezibonakalayo | Izinto zokwakha ezinamaphoyinti ahlukene ancibilikayo azinqunywa kalula | Kungenzeka, kepha kunengozi yokuhlehlisa |

| Izakhiwo zeSandwich ezinama-cavities | Lokhu akunakwenzeka nge-CO2 laser | Amandla alinganiselwe |

| Izinto zokusika ngokufinyelela okulinganiselwe noma okulimazayo | Akuvamile ukuba kwenzeke ibanga elincane nekhanda elikhulu lokusika le-laser | Limited ngenxa yebanga elincane phakathi kwe-nozzle kanye nokuqukethwe |

| Izakhiwo zezinto ezisikiwe ezithinta ukucubungula | Izici zokumunculwa kwezinto ezibonakalayo ku-10.6m | Ubulukhuni bezinto ezibonakalayo buyisici esibalulekile |

| Ubukhulu bezinto ezibonakalayo lapho ukusika noma ukucubungula kungokomnotho | ~ 0.12 "kuya ku-0.4" ngokuya ngezinto ezibonakalayo | ~ 0.4 "kuya ku-2.0" |

| Izicelo ezijwayelekile zale nqubo | Ukusika insimbi eshifini yokuqina okuphakathi kokucutshungulwa kwensimbi | Ukusika itshe, ubumba, kanye nezinsimbi zobukhulu obukhulu |

Ukutshala imali kokuqala kanye nezindleko ezisebenzayo zokusebenza

| Beka | I-CO2 laser | Ukusika kwamanzi amanzi |

| Ukutshalwa kwemali kwenhlokodolobha yokuqala kuyadingeka | $ 300,000 nge-20 kw pump, kanye netafula le-6.5 'x 4' | $ 300,000 + |

| Izingxenye ezizoguga | Ingilazi evikelayo, igesi Ama-nozzles, kanye nothuli zombili nezihlungi zezinhlayiyana | Amanzi Jet nozzle, agxile ama-nozzle, nazo zonke izingxenye eziphakeme kakhulu njengama-valves, ama-hoses kanye nezimpawu |

| Isilinganiso sokusetshenziswa kwamandla kwesistimu ephelele yokusika | Thatha i-1500 watt Comeraser: Ukusetshenziswa kwamandla kagesi: 24-40 kw I-Laser Gas (CO2, N2, yena): 2-16 l / h Ukusika igesi (O2, N2): 500-2000 l / h | Thatha iphampu ye-20 kw: Ukusetshenziswa kwamandla kagesi: 22-35 kw Amanzi: 10 l / h Abrasive: 36 kg / h Ukulahlwa kwemfucuza yokusika |

Ukunemba kwenqubo

| Beka | I-CO2 laser | Ukusika kwamanzi amanzi |

| Ubukhulu obuncane bokusika slit | 0.006 ", kuya ngesivinini sokusika | 0.02 " |

| Sika ukubukeka komhlaba | Ukusika komhlaba kuzokhombisa ukwakheka okwenziwe ngenhla | Ingaphezulu elisikiwe lizobonakala sengathi liqhume isihlabathi, kuya ngesivinini sokusika |

| Degree of imiphetho yokusika ukuze ihambisane ngokuphelele | Kuhle; ngezikhathi ezithile zizokhombisa imiphetho ye-conical | Kuhle; Kukhona umphumela "ohambisana" kuma-curve endabeni yezinto zokwakha |

| Ukucubungula ukubekezelela | Cishe 0.002 " | Cishe 0.008 " |

| Degree of burring ekusikeni | Kuvela umngcele wengxenye kuphela | Akekho u-Burring Owenzeka |

| Ukucindezela okushisayo kwezinto ezibonakalayo | I-Deformation, izinguquko ezinomoya ovumayo nokwakheka zingavela ezintweni ezibonakalayo | Akukho ukucindezela okushisayo okwenzeka |

| Amabutho asebenza ngendlela eqondiswe ephepheni noma ngejethi yamanzi ngesikhathi sokucubungula | Ingcindezi yegesi iyavela Izinkinga ezincanyana Izisebenzi zokusebenza, ibanga ayikwazi ukunakekelwa | Okuphakeme: mncane, izingxenye ezincane zingalungiswa kuphela ukuze zilinganiselwe |

Ukucatshangelwa Kwezokuphepha Nendawo Yokusebenza

| Beka | I-CO2 laser | Ukusika kwamanzi amanzi |

| Ukuphepha KomuntuIzidingo Zemishini | Izibuko zokuvikela ukuvikelwa kwe-laser azidingeki ngokuphelele | Izibuko zokuvikela zokuvikela, ukuvikelwa kwezindlebe nokuvikelwa ekuxhumaneni ne-jet yamanzi ephezulu kuyadingeka |

| Ukukhiqizwa intuthu nothuli ngesikhathi sokulungisa | Kwenzeka; Amapulasitiki namanye ama-alloys wensimbi angakhiqiza amagesi anobuthi | Ayisebenzi ngokusika kwamanzi |

| Ukungcoliswa komsindo nengozi | Phansi kakhulu | Kuphakama ngokungafani |

| Izidingo Zokuhlanza Umshini ngenxa yenqubo yokudideka | Hlanza okuphansi | Hlanza phezulu |

| Ukusika imfucuza kukhiqizwe yinqubo | Ukusika imfucuza kusesimweni sothuli oludinga ukukhishwa kwe-vacuum nokuhlunga | Inani elikhulu lokusika imfucumfucu livela ngenxa yokuxuba amanzi angenayo |