I-Oval Tube | Isixazululo sokusika i-Laser - Ubuchwepheshe obugcwele be-Oval Tube Steel Processing

Iyini i-Oval Tube kanye Nohlobo lwama-Oval Tubes?

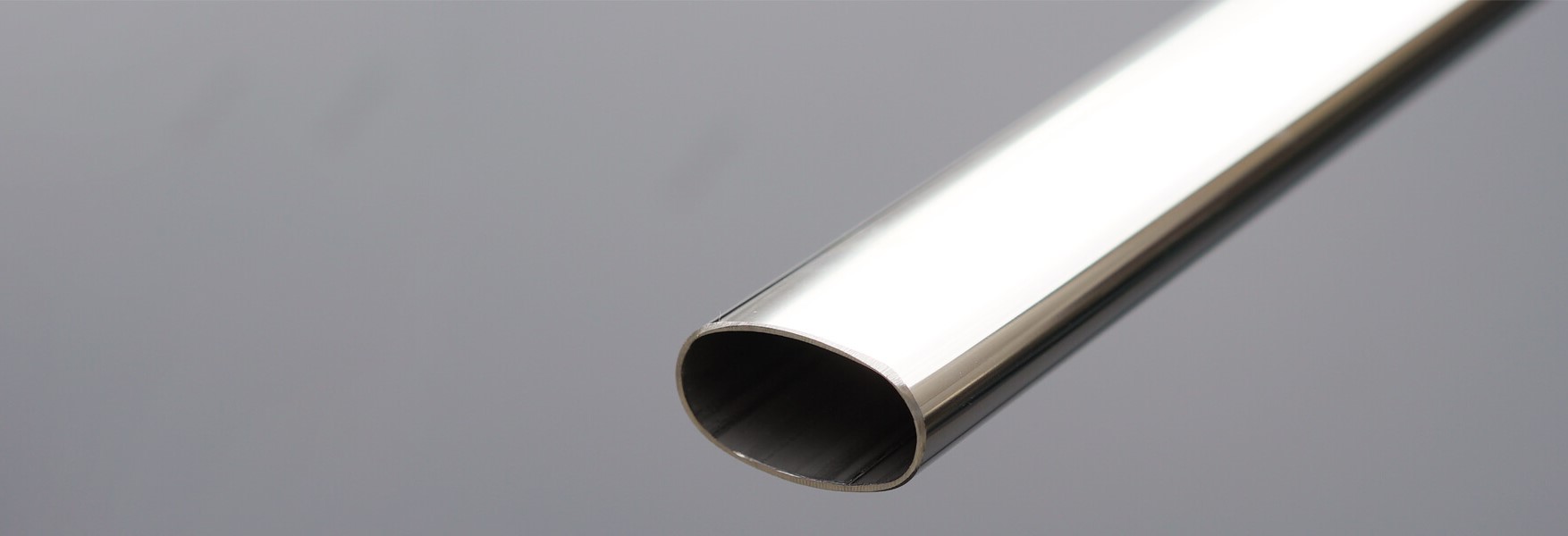

I-Oval Tube iwuhlobo lwamashubhu ensimbi amise okwesipesheli, ngokokusetshenziswa okuhlukile, ineshubhu eyisiyingi emimo ehlukene, njengamashubhu ensimbi ayi-elliptical, amapayipi ensimbi angenamthungo, amapayipi ensimbi ayisicaba, amapayipi ensimbi anamagqabhagqabha, amapayipi ensimbi anamagqabhagqabha, amapayipi ensimbi ayisicaba, amapayipi ensimbi ayisiyingi ayindilinga ahlukahlukene. Amashubhu ensimbi anembile anoma yimuphi usayizi anogqinsi luka-1mm-30mm.

Kusukela Ezintweni, kufaka phakathi i-aluminium oval tube, i-steel oval tube, i-stainless steel oval tube nokunye.

Ukusetshenziswa kwe-Oval Tube?

I-Oval Tube isetshenziswa kabanzi embonini yezimotoukuphuma kwe-oval tube, umhlobiso, izinto zokuhamba, ukwakhiwa kwesikhumulo sezindiza, ukusekelwa kwebhuloho, igaraji elinezinhlangothi ezintathu, ukukhangisa kwangaphandle, okokusebenza kokuqina, izinhlelo zokusebenza zezimonyo ezifana ne-DOT guardrails, okokusebenza kwamandla omoya, ukukhiqiza izimoto, nezinye izimboni.

Iyini inzuzo ye-Oval Tube?

1. Kusukela oqwembeni lwangaphandle, izingqimba ezimbili ze-hot-dip galvanizing kanye nopende wokufutha zisetshenziselwa ukuvimbela ukugqwala. Ungqimba lwangaphakathi lwangaphakathi lwenziwe ngamapayipi ensimbi angenamthungo anezimbambo zangaphakathi eziphumayo kanye namapayipi epulasitiki e-polypropylene ngokusebenzisa ubuchwepheshe bokucubungula obuyingqayizivele.

2. Ishubhu eliyi-elliptical liqinile futhi linezinga elithile lokuthamba. Akulula ukukhubazeka nge-extrusion futhi amelana nomthelela. Ukwethenjwa kokufakwa kuphezulu, futhi akukho embrittlement ngaphansi kwegesi nokukhanya kwelanga.

3. Ukumelana nesimo sezulu nokumelana nokucindezela. Ukushisa kwamapayipi okushisa: 0°C~75°C, izinga lokushisa lifinyelela ku-95°C ngomzuzwana, ingcindezi≤1.5MPa; Ukupholisa ipayipi lamanzi lokushisa lokushisa: 0°C~55C, ingcindezi≤2.0MPa.

4. Ukushisa okuqinile okushisayo nokumelana nokugqwala. Ifanele ukungcwatshwa ebumnyameni kodwa futhi ingafakwa ebumnyameni.

5. Hlanza okungenabo ubuthi, okunempilo, futhi okuphephile. Amapharamitha wokusebenza ahlukahlukene ahlangabezane nezimfuneko zamazinga ekhwalithi woMnyango Wezempilo.

6. Imbobo yangaphakathi ibushelelezi futhi ihlanzekile, ayigqwali, ayiqoqi, futhi inani lokugeleza eliphelele lilikhulu ngo-25% -30% kunepayipi lensimbi elinobubanzi obufanayo. Awukho umonakalo wobubanzi bepayipi ekuhlanganiseni.

7. Ubuchwepheshe bokucubungula obuhlukile bukhethiwe. Iphethini yesakhiwo esinjengenethi eyi-convex ikhiqizwa futhi icutshungulwe endaweni engaphakathi yepayipi lensimbi engenamthungo, okwandisa kakhulu ukuslayida phakathi kwepayipi lensimbi elingaphezulu kanye nepayipi lepulasitiki elingaphakathi.

Ngokulandelayo, ukungahambisani kwe-deformation yokushisa phakathi kwamapayipi angaphakathi nangaphandle kuyancishiswa ngokunengqondo. I-thermal expansion coefficient yepayipi eliyielliptical ngu-2.5×(1/100000)/°C, futhi impilo yesevisi iphindwe izikhathi ezingu-5 kunepayipi lensimbi elidiphu elishisayo.

8. Ukufakwa kulula futhi kuthembekile. Ishubhu ixhunywe izixhumi ze-wallboard ezikhishwa ngokushesha, ezingadingi ukuthunga, ukonga isikhathi nomzamo.

Ishubhu yesikwele esinobubanzi obukhulu inendawo yokufaka isicelo esivame kakhulu, ngoba ubukhulu bayo bodonga bukhulu kakhulu, ngakho-ke ingakwazi ukuthwala ukucindezela okukhulu kokusebenza. Ngokuvamile, ingasetshenziswa njengempahla eluhlaza yezingxenye ezingenalutho, ezisetshenziselwa ukuthwala amandla kanye nokusetshenziswa kwamapayipi abalulekile.

Eqinisweni, ingasetshenziswa njengamashubhu esakhiwo sezindiza, amapayipi okuhlola uwoyela ongahluziwe, namapayipi emishini ye-petrochemical. Lapho kusetshenziswa amapayipi ensimbi yesikwele, kufanele futhi ahambisane nezinqubomgomo nemithethonqubo efanele. Ngakho-ke, ukusetshenziswa okuyinhloko okuhlukile kudinga ukusetshenziswa kokucaciswa okuhluke kakhulu namamodeli wamapayipi. Lokhu futhi kubonisa imfuneko eyinhloko yokusetshenziswa kwamapayipi e-elliptical, ikakhulukazi Lapho uthutha izinto eziyingozi kakhulu futhi ezivuthayo, kuyadingeka ukuthola amapayipi ensimbi angenasici anezincazelo ezifanele namamodeli, ukuze izingozi zokuphepha zingagwenywa ngokunengqondo.

Indlela Yokukhiqiza Amashubhu Oval?

Ukhiye wemigqa yenqubo yokukhiqiza ohlotsheni lomkhiqizo. Kusukela ezintweni ezingavuthiwe kuya emikhiqizweni eqediwe, uchungechunge lwezinqubo zobuchwepheshe kufanele ludluliselwe. Yonke inqubo yalobu buchwepheshe bokucubungula kufanele yenziwe ngezinhlobonhlobo zemishini yezimboni, i-welding kagesi, izinhlelo zokulawula ugesi, nemishini yokuhlola. Izinhlobo ezehlukene zemishini nemishini zinezinhlobonhlobo zezakhiwo ezisebenzayo ngokuya ngemithethonqubo ehlukene yokukhiqiza.

1. Izinyathelo ezijwayelekile zeshubhu elishiselwe imvamisa ephezulu: ukuqaqa-okushisayo-okugoqiwe kwe-strip ukucaba-ekupheleni nasekuqedeni ukusika-hot-rolled strip butt welding-looper discharge -Forming-Electric welding-Ukususwa kwama-burrs-Die-Flaw discover-Fly cutting-Initial inspection-Initial yokuhlola ipayipi-Ukukhiqizwa kwensimbi engenambhobho ukukhiqizwa kwensimbi engenamthungo-Flaw ukuthola-Ukukopisha kanye enamathela-Imikhiqizo eqediwe.

2. Ishubhu yensimbi eyi-elliptical ehlanganisiwe ngokungenamthungo ibizwa nangokuthi i-elliptical steel pipe, okuyinqubo yokukhiqiza ipayipi elingenamthungo.

3. Indlela yokugoba ye-stainless steel elliptical tube ngokuvamile isebenzisa indlela yomgomo we-cam. Umphumela wokuthi indlela yomgomo we-cam isetshenziswa kangaki ukucubungula amashubhu e-elliptical ensimbi engenasici enama-arc amaningi kuwumphumela wokuqinisekisa okuningi. Wonke umuntu uzwile ngekhamera. I-camshaft iyajikeleza, umlandeli uxhunywe ku-cam contour, futhi umlandeli wenza ukunyakaza okuphindaphindiwe.

Ngokwalesi simiso: inqobo nje uma ama-arcs angu-5 eklanyelwe isikhunta, futhi ubude bongqimba olumaphakathi lwe-arc ngayinye bulingana nobude bongqimba olumaphakathi lwe-arc yomkhiqizo (ngoba i-R ekubunjweni ene-rebound enkulu incane kune-R emkhiqizweni), Isikhunta simaphakathi ne-arc ene-engeli enkulu efakiwe njengesikhungo sokujikeleza. Ingxenye eqhutshwayo isebenzisa isilinda. Ngenxa yokucindezelwa kwegesi kanye ne-valve yokusiza ingcindezi ingasetshenziswa ukulungisa ukucindezela, uma ingcindezi yokugoba inkulu, ungasebenzisa isilinda samandla amabili. , Induku yesilinda ixhunywe esihlalweni esigobile, futhi kukhona isitimela esiqondisayo ngaphansi kwesihlalo se-roller. Izici ezibalulekile ezithinta ukushwabana kweshubhu okusaqanda yijubane lokugoba kanye nolwelwesi lwepayipi le-oval.

Indlela yokulawula isivinini sokugoba? I-valve yokugeleza elinganayo ingasetshenziswa ukulawula ijubane eliya phambili nangemuva le-cylinder eyinhloko. Uma irediyasi yokugoba engu-R yento incane, isilawuli sesivinini kufanele sifaneleke.

Ungawasika Kanjani Amashubhu Okuyiqanda Kube Imikhiqizo Efunwa Yi-Yur?

Ngokwezidingo ezihlukene zokusika, ungasebenzisa ukusika okwenziwa ngesandla noma izindlela zokuzisika. Futhi ukusebenzisa izindlela ezahlukene zokusika izindleko zizohluka kakhulu. Njengomshini wokusaha uzonqamula ishubhu kodwa awukwazi ukumboza ishubhu, i-tube cutter nayo iyithuluzi elincane lokusika ishubhu elincane.

Uma ufuna ukusebenza kahle okuphezulu futhi akukho mshini wokusika onqunyelwe wokusika, khona-ke aumshini wokusika we-fiber laser tubekuzoba ukukhetha kwakho okuhle kakhulu.

Kungani Umshini Wokusika we-Tube Laser kuyisinqumo sakho esingcono kakhulu sokucubungula i-Oval Tube?

I-Metal Laser Cutting iyindlela yokushisa ephezulu engathinteki kanye nendlela yokusika ngesivinini esikhulu, akukho ukuhlanekezela ngesikhathi sokusika, ukunemba kufinyelela ku-0.1mm, kungasika noma yikuphi ukuma ebusweni be-oval tube yakho. Umphumela ophelele wokusika we-laser ku-aluminium oval tube, ishubhu yensimbi e-oval, ishubhu yensimbi engagqwali e-oval nokunye.

I-Golden Laser ingomunye wabakhiqizi bemishini yokusika ishubhu ye-laser e-China, kwesokudla inikeza isisombululo esigcwele sokusika i-laser senqubo ye-Oval Tubes. Ngezansi ukuhlaziya ukusetshenziswa kwamakhasimende ethu umshini wokusika we-laser wokusika amashubhu a-oval, mhlawumbe nawe unesidingo esifanayo sokusika i-oval tube exhaust njengaye.

Isidingo Sokusika Ishubhu Eyisiyingi Yekhasimende:

89*38 kanye namashubhu okusaqanda angu-114*64mm, Ubude busuka ku-4.5m—6m. Ukusika izimo ezihlukene kanye nesidingo se-Tailer "0".

Ungahlangabezana kanjani nesidingo sokucubungula okuzenzakalelayo kweKhasimende esidingweni sokusika ishubhu ye-carbon ovel emise okwesipesheli?

1. Ukuze ulayishe ngokuzenzakalelayo amashubhu ensimbi, ungasebenzisa umshini wokuphakela amashubhu, unokulawula okunembile kwe-servo ukuze uqinisekise ukukhethwa okunembile kwamashubhu, bese ukondla ishubhu-pushing tube-ukulinganisa ubude beshubhu. Bonke baqinisekisa ukuthi ipayipi ithunyelwa emshinini wokusika we-laser ngokuzinzile nangokunembile

2. Idatha yohlelo lwesilawuli se-PA CNC kanye nesistimu ye-auto feeder yabiwa, okuqinisekisa ukunemba kwe-Clamping position-first cutting position-Indawo yempahla elahlekile ilethwa ngokunembile. Yonke inqubo ihamba kahle.

3. Izinto ezenziwe ngokwezifiso zemihlathi yangaphambili nangemuva iqinisekisa ukunemba kokusika kwepayipi lensimbi eliyisiyingi.

4. Ngenxa yokuthi ubude bepayipi bukhulu ngokuqhathaniswa, i-clamp ye-feed kanye nokusekelwa kwemishini kuzophazamisa, ngakho umsebenzi wethu wokwabelana ngedatha ungaxazulula le nkinga kahle. Sizokhetha ngokuzenzakalelayo indlela yokukhipha ipayipi ngokusho komumo wepayipi ohlukene.

5. Uhlelo lokusika i-laser lushintshwa ngokuzenzakalelayo ngaphandle kokungenelela komuntu.

Ixazululwa Kanjani Inkinga Yepayipi kanye Nokuklwebheka Kwezizipho Ezenziwe Ngokwezifiso ezingase Zenzeke Ngesikhathi Sokusika I-Laser?

Ngemuva kokuhlolwa okuningi, i-radian ekhethekile yokugcina, nokucubungula. Ixazulule inkinga yokuklwebheka

Indlela Yokuqinisekisa Ukunemba Kwe-Tube Laser Cutting?

Njengoba inqubo yokukhiqiza ipayipi ye-eye-seam ihluke kuleyo yepayipi evamile, kunzima kakhulu ukufeza ukuqondisa okujwayelekile kanye nokuhlukunyezwa kwepayipi.

Ukulungiswa okukhethekile kanye nobuciko obuyingqayizivele, ukuhlolwa okuqhubekayo kwamapayipi angu-100, ukunemba nokwaneliseka kwamakhasimende!

Ungayithola Kanjani I-Zero Tailings

Ngokusho kwezimpawu zehluzo zekhasimende, ama-tailings angu-0 aqinisekisiwe phakathi kwesigamu semitha, umsebenzi wokuvula ikhadi, izilungiselelo ze-Lantek's (Professiona Tube Nesting Software), amandla okugoqa alungisekayo we-chuck, njll., ekugcineni afinyelele umsila ongu-0.

Ividiyo ye-OvalI-Tube Laser Cutting MachineAutomatic Cutting Isixazululo Ukuze Reference Yakho.

Uma unentshisekelo noma unesidingo esifanayo somshini wokusika we-laser oval tube, pls ukhululeke ukuxhumana nathi.