Iphuzu lamanje lobuhlungu embonini yokukhiqiza ifenisha yensimbi

1. Le nqubo iyinkimbinkimbi: ifenisha yendabuko ithatha inqubo yokukhiqiza yezimboni yokukha-i-saw bed cut-turning machine processing-slanting surface-proofing position proofing and punching-drilling-clening-transfer welding idinga izinqubo ezingu-9.

2. Kunzima ukucubungula ithubhu elincane: ukucaciswa kwezinto zokusetshenziswa kwefenisha yokukhiqiza akuqinisekile. Encane kunawo wonke10mm*10mm*6000mm, futhi ubukhulu bodonga lwepayipi ngokuvamile0.5-1.5mm. Inkinga enkulu ekucutshungulweni kwepayipi elincane ukuthi ipayipi ngokwalo linokuqina okuphansi futhi likhubazeka kalula ngamandla angaphandle, njengokugoba kwamapayipi, ukusonteka, nokuqhuma ngemva kokukhipha. Izinqubo zendabuko zokucubungula, njengokusika umshini wokusaha, isigaba sokucutshungulwa komshini wokusaha kanye ne-beveling, ukubhoboza ngesibhakela, ukubhoboza umshini wokumba, njll., izindlela zokucubungula othintana nazo eziphoqelela ukwakheka kwepayipi ukuthi kukhubazwe yi-extrusion yamandla angaphandle, kanye nezinqubo eziningi kangaka nabantu abaningi ukulungisa, okudla isikhathi futhi kuyakhandla.

3. Ukunemba okungalungile kwemishini: Ngaphansi kwendlela yokucubungula yendabuko yepayipi yefenisha yensimbi, ukunemba okuphelele kwepayipi akukwazi ukuqinisekiswa. Noma ngabe ukwenza imishini efana nomshini wokusaha, umshini wokubhoboza noma umshini wokubhoboza, kunamaphutha omshini, ikakhulukazi imishini yokucubungula enezinga eliphansi lokulawula okuzenzakalelayo. Lapho ukulandelana kwenqubo kuba, kulapho iphutha lomshini linqwabelana. Zonke lezi zindlela zokucubungula ezingenhla zidinga ukungenelela komuntu ekulawuleni inqubo, futhi iphutha lomuntu lizokwengezwa ephutheni lokugcina lokunemba komkhiqizo. Ngakho-ke, ukunemba kwendlela yokucubungula yezinqubo eziningi zendabuko akulawuleki futhi kuqinisekisiwe. Esigabeni sokugcina somkhiqizo, ukulungiswa nokulungiswa kwezandla kuyisimo esivamile.

4. Ukusebenza kahle kokucubungula okuphansi: Umshini we-sawing unezinzuzo ezithile zokusika okuvumelanayo kanye ne-chamfering yamapayipi amaningi, kodwa ukusebenza kahle kokusika kokuvula ipayipi kuphansi kakhulu, futhi kuyadingeka ukushintsha i-angle yokusika kanye nesimo se-saw blade yokubeka okuningi nokusika, okungasebenzi kahle noma okufinyelelekayo. Lawula ukunemba. I-Punch pressing ingasetshenziselwa ukubhoboza inqwaba yezimbobo zomumo ezijwayelekile njengezimbobo eziyindilinga nezikwele. Nokho, kunezinhlobo eziningi izinhlobo imbobo embonini ifenisha. Umshini wokubhoboza unamandla amaningi okucubungula izimbobo ezinjalo, ngaphandle uma ikhasimende libangela Sebenzisa isipiliyoni esiningi kanye nezindleko zokuthuthukisa ukubunjwa okuhlukahlukene okuhlukahlukene. Wonke umuntu uyazi ukuthi umshini wokumba ungacubungula izimbobo eziyindilinga kuphela, futhi ukucubungula kunqunyelwe kakhulu. Imikhawulo yokucubungula kanye nokungasebenzi kahle kwenqubo ngayinye kubangela ukungasebenzi kahle ekukhiqizweni komkhiqizo wonke.

5. Izindleko eziphezulu zokusebenza: Ngokusaha, ukubhoboza nokubhoboza ngendlela evamile yokucubungula, isici esikhulu kunazo zonke ukungenelela komuntu. Ukusebenza kwedivayisi ngayinye kudinga ukugadwa mathupha, ngoba ukuzenzekelayo kwemishini enjalo kuphansi kakhulu. Ukuze kucutshungulwe izinto ezinjalo ezingewona amashidi amapayipi, ukulawulwa okwenziwa ngesandla kuyadingeka engxenyeni ngayinye yokondla, ukubeka, ukucubungula nokubuyisela kabusha. Ngakho-ke, ingabonakala kaningi ku-workshop yemboni yokucubungula ifenisha, imishini eminingi, abasebenzi abaningi. Kulezi zinsuku njengoba isimo semakethe sithuthuka, abanikazi bamabhizinisi bakhala ngokuthi abasebenzi baya ngokuya behamba, futhi kuba nzima ukuqasha. Izidingo zamaholo abasebenzi nazo ziyakhula. Izindleko zomsebenzi zingase zibangele ingxenye enkulu yenzuzo yebhizinisi.

6. Ikhwalithi yomkhiqizo engalungile: Ukunemba kanye nekhwalithi yepayipi eliqediwe lithinta ngokuqondile umkhiqizo wokugcina. I-Burr, i-peripheral deformation yomshini, ukungcola odongeni lwangaphakathi lwepayipi, njll. akuvunyelwe ukukhiqiza ifenisha ephezulu. Nokho, kungakhathaliseki ukuthi ukusika umshini wokusaha, ukubhoboza, noma ukubhoboza, akungabazeki ukuthi lezi zinkinga zizodalulwa ngemva kokucubungula ipayipi. Umsebenzi wokukhipha mathupha, ukusika, nokuhlanza emisebenzini elandelayo awunakugwenywa.

7. Kukhona ukuntuleka okungathi sína kokuguquguquka: Namuhla, isidingo sabathengi siya ngokuya sithandwa, ngakho-ke umklamo wefenisha wesikhathi esizayo nakanjani ungumuntu ngamunye. Umshini wokusaha wendabuko, umshini wokubhoboza, umshini wokubhoboza nezinye izinto zokusebenza kuyisidala, futhi ubuciko obulula abukwazi ukusekela umklamo omusha kanye nogqozi lokudala. Khanyisa eqinisweni. Ukungasebenzi kahle, ikhwalithi ephansi, nokushiyeka kwezindleko eziphezulu zemodi yokucubungula evamile kuzophazamisa kakhulu ijubane locwaningo nokuthuthukiswa kwemikhiqizo emisha, futhi kunikeze imakethe isiqalo.

Yiziphi izinto ezintsha ezingalethwa ifenisha umsiki wepayipi we-laser othomathikhi ngokugcwele

imboni yokukhiqiza? Yiziphi izici zemishini?

1. Amandla amasha ayinhloko ekucutshungulweni kwamapayipi ensimbi ye-bismuth: ukusika i-fiber laser kuyisikhali esisha sokucubungula insimbi eminyakeni yamuva. Kamuva, kancane kancane ishintsha ukugunda kwendabuko, ukubhoboza, ukubhoboza nokusaha. Izinto zepayipi nazo ziyinsimbi, futhi ipayipi yemboni yefenisha yenziwe ngensimbi engagqwali, ehambisana nezinzuzo zokusika i-fiber laser. I-Fiber laser high-efficiency photoelectric conversion ukusebenza kahle, ikhwalithi enhle kakhulu ye-boam, high focusing density laser energy, igebe elihle lokusika, lingasetshenziswa embonini yefenisha yokucubungula amapayipi. I-rotary chuck yomshini wokusika we-laser we-Vexo ozenzakalelayo ngokugcwele inejubane elijikelezayo elifika ku-120 rpm, kanye nekhono le-fiber laser lokusika insimbi engagqwali ngesivinini esiphezulu. Ukuhlanganiswa kokubili kwenza ukusebenza kahle kwepayipi kuyingxenye yomzamo. Ngesikhathi esifanayo, lapho i-fiber laser isika ipayipi, ikhanda lokusika le-laser alixhumani nepayipi, kodwa i-laser-projected phezu kwepayipi ukuze incibilike futhi inqunywe, ngakho-ke ingeyemodi yokucubungula okungeyona yokuxhumana, igwema ngokuphumelelayo inkinga yokuguqulwa kwepayipi ngaphansi kwemodi yokucubungula yendabuko. Isigaba esisikwe nge-fiber laser sihlanzekile futhi sibushelelezi, futhi akukho burr ngemva kokusika. Ngakho-ke, izinzuzo ezimbili zokusebenza kahle kanye nekhwalithi ziyisiqinisekiso esibalulekile sokusika i-fiber laser ukuze sibe amandla amasha ayinhloko ekucubunguleni amapayipi ensimbi.

2. Ukucushwa okwenziwe ngokwezifiso ukusiza ukucubungula ukusebenza kahle nokuthuthukiswa kwekhwalithi: embonini yefenisha, izinto ezincane, ezincane, ezibonakalayo ziyizici zensimbi engagqwali, sisebenzisa ukucushwa okuhlosiwe ukuze sithuthukise ukusebenza kahle kokucubungula kanye nekhwalithi yokucubungula yepayipi yemboni yefenisha. I-module ekhethekile ye-fiber laser, i-fiber ekhethekile, i-non-conventional focal length fibre laser cutting head, zonke izinzuzo zokucushwa zigxile ekhonweni lokusika lepayipi elikhethekile embonini yefenisha, ukusebenza kahle kwepayipi lensimbi engagqwali lokucaciswa okufanayo kusikwa umshini wethu wokusika ojwayelekile we-fiber laser Cishe u-30%, kuyilapho uletha imiphumela engcono yokusika.

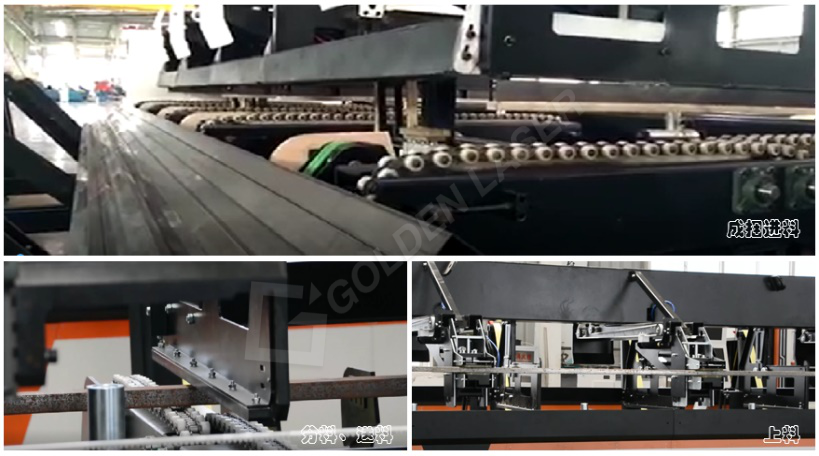

3. Ukukhiqizwa okuzenzakalelayo kweqoqo lamapayipi: Ngemva kokuba amapayipi ahlanganisiwe ebekwe emshinini wokuphakelayo ozenzakalelayo, inkinobho eyodwa iyaqalwa, futhi amapayipi aphiwa ngokuzenzakalelayo, ahlukaniswe, ondliwe, aboshwe ngokuzenzakalelayo, ondliwe, asikwe futhi alayishwe ngesikhathi esisodwa. Ngenxa yomsebenzi wethu wokulayisha nokuthulula othomathikhi othuthukiswe emshinini wokusika wepayipi we-laser ozenzakalelayo ngokugcwele, ipayipi lingabona ukuthi kungenzeka yini ukucutshungulwa kweqoqo. Izinto zamapayipi amancane embonini yefenisha zithatha indawo encane. Uhlobo olufanayo lwemishini lungapakisha amapayipi amaningi emthwalweni owodwa, ngakho-ke kunezinzuzo eziningi. Umuntu oyedwa usemsebenzini, futhi lonke lolu hlelo luphothulwa ngokuzenzakalelayo. Lokhu kuwukubonakaliswa kokusebenza kahle.

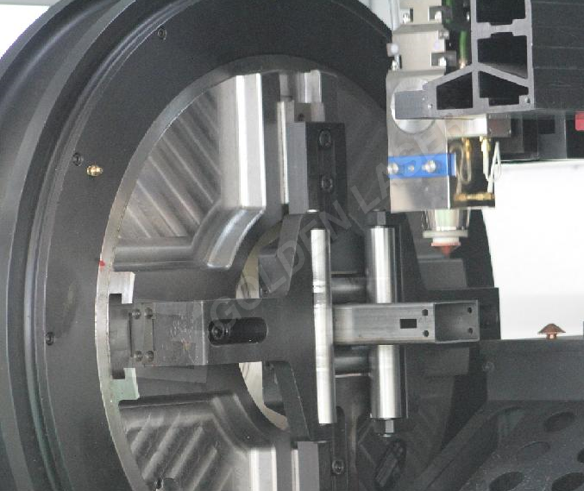

4. Ukuphumula kwe-Tube clamping: Kushubhu elincane lemboni yefenisha, i-laser cutting chuck iqinile kakhulu. Uma i-clamping force inkulu kakhulu, ipayipi likhubazekile kalula, amandla okubamba mancane kakhulu, futhi ubude bepayipi bude. Phakathi nenqubo yokusika, ipayipi ijikeleza ngesivinini esikhulu futhi ikhishwa kalula. Ngakho-ke, amandla okugoqa we-chuck yemishini yokusika ipayipi embonini yefenisha kufanele alungiseke, futhi indlela yokulungisa iphutha kufanele ibonakale kalula. I-chuck ye-pneumatic ezizimisayo elungiselelwe umshini wokusika ipayipi le-laser othomathikhi ngokugcwele ingakwazi ukubona ukuzimisa endaweni yokubopha ipayipi, uma isendaweni yokubopha, futhi isikhungo samapayipi sisendaweni kanye. Ngesikhathi esifanayo, amandla e-chuck clamping atholakala kumfutho womoya wokufaka. Ulayini wokufaka igesi ufakwe i-valve elawula umfutho wegesi, futhi amandla okubamba angalungiswa kalula ngokuzungezisa i-knob ku-valve elawula umfutho womoya.

5. Ikhono elisebenzayo nelinokwethenjelwa lokusekela eliguquguqukayo: Uma ubude bepayipi buba bude, kubi nakakhulu ukuguquguquka kwepayipi ngemva kokuba imisiwe. Ngemuva kokuthi ipayipi ilayishiwe, nakuba i-chuck iboshiwe ngaphambi nangemuva, ingxenye ephakathi yepayipi izokwehla ngenxa yamandla adonsela phansi, futhi ukujikeleza kwepayipi ngesivinini esikhulu kuzoba isimo sengqondo sokweqa, ngakho ukusika kuzothinta ukunemba kokusika kwepayipi. Uma indlela evamile yokulungisa i-manual yokusekelwa kwezinto eziphezulu yamukelwa, kuphela izidingo zokusekela zepayipi eliyindilinga kanye nepayipi yesikwele ingaxazululwa, kodwa ngokusikwa kwepayipi yohlobo lwesigaba esingavamile njengepayipi elingunxande kanye nepayipi le-elliptical, ukulungiswa kwesandla kokusekelwa kwezinto eziphezulu akuvumelekile. . Ngakho-ke, ukwesekwa okuphezulu okuntantayo nokusekelwa komsila kokucushwa kwemishini yethu kuyisixazululo sochwepheshe. Lapho ipayipi lizungeza, lizobonisa ukuma okuhlukene esikhaleni. Ukusekelwa kwezinto eziphezulu ezintantayo kanye nokusekelwa kwezinto zomsila kungalungisa ngokuzenzakalelayo ukuphakama kokusekela ngesikhathi sangempela ngokusho kokushintsha kwesimo sepayipi, ngakho-ke kungaqinisekisa ukuthi phansi kwepayipi kuhlale kungenakuhlukaniswa kusukela phezulu kwe-shaft yokusekela, edlala ukusekela okuguquguqukayo kwepayipi. umphumela. Ukwesekwa kwezinto eziphezulu ezintantayo kanye nokwesekwa kwempahla yomsila ontantayo kusebenza ndawonye ukuze kugcinwe ukuzinza kokuma kwepayipi ngaphambi nangemuva kokusika, ngaleyo ndlela kuqinisekisa ukunemba kokusika.

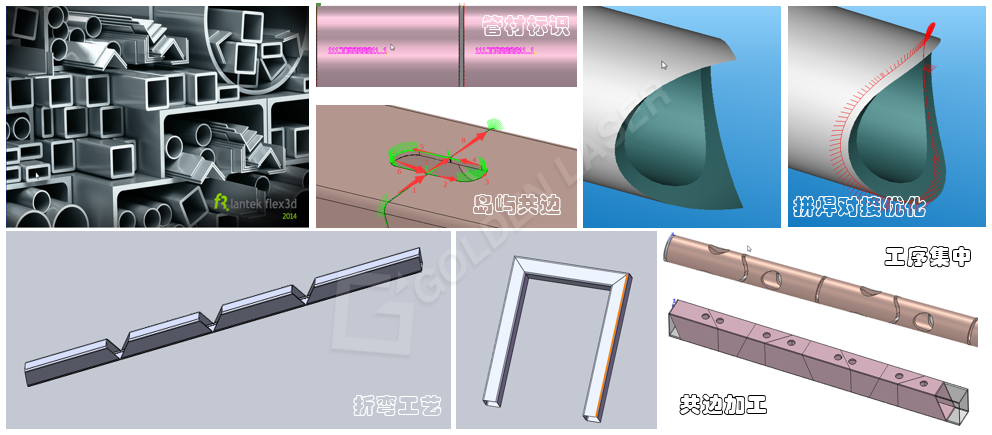

6. Inqubo yokugxilisa ingqondo nokucubungula ukwahlukahlukana: sebenzisa isofthiwe yokudweba ye-3D ukuze udizayine amaphethini ahlukahlukene adinga ukucutshungulwa, njengokusikwa, i-beveling, ukuvulwa, ukuphawula, ukumaka, njll., bese uwaguqulela ezinhlelweni zemishini ye-NC ngesinyathelo esisodwa ngokusebenzisa isofthiwe yokufaka isidleke. , okokufaka kusistimu ye-CNC yobungcweti yokucushwa kwedivayisi, bese uthola imingcele yenqubo yokusika ehambisanayo kusizindalwazi senqubo, futhi umshini ungaqalwa ngenkinobho eyodwa. Inqubo yokusika ezenzakalelayo iqeda ukusaha okujwayelekile, imoto, ukubhoboza, ukubhoboza nezinye izinqubo. Ukuphothulwa kwenqubo endaweni eyodwa kuletha ukunemba kokucubungula okulawulekayo nokuqinisekisiwe, kanye nokusebenza kahle okuphezulu kanye nezindleko eziphansi. Lokhu kwengezwa nokususwa kwezinkinga zezibalo kumele kucace kubo bonke osomabhizinisi.

7. Ukusetshenziswa kochwepheshe bemishini yokusika i-fiber laser yamapayipi embonini yefenisha yensimbi kulethe izinguquko ezintsha kubuchwepheshe bokucubungula amapayipi. Selokhu saqala ucwaningo nokuthuthukiswa komshini wokusika i-fiber laser othomathikhi ngokugcwele, sizibeke endaweni yethu embonini, okwenza imboni ijule, ichwepheshile, futhi icophelele. Imboni yefenisha yensimbi isibe yisibonelo somshini wethu wokusika amapayipi. Emgwaqweni we-R&D, ukuhlola nokusungula izinto phakathi neminyaka edlule, siqongelele ulwazi oluningi lwezobuchwepheshe futhi sathuthukisa izinto eziningi ezintsha ezisebenzayo nezisha embonini yokukhiqiza ifenisha. Inqubo. Isidingo sokuqala sokushiselwa, manje singaboshelwa futhi silungiswe; isidingo sokuqala sokuhlukaniswa, singagoba ngokuqondile; ukusetshenziswa kwamapayipi okuqala kuphansi kakhulu, manje kungasebenzisa umsebenzi wokusika onqenqemeni ovamile ukuze kuzuzwe ukonga okungcono kwamapayipi kanye nemikhiqizo eminingi Out, nokunye, lawa masu amasha okucubungula asetshenziswa embonini yefenisha yokucubungula ipayipi, futhi izinzuzo yiqiniso abasebenzisi bemishini yethu.

Laser Cutting Machine For Metal Ifenisha