Ukusetshenziswa komshini wokusika i-Stainless Steel Laser ku-Decoration Engineering Industry

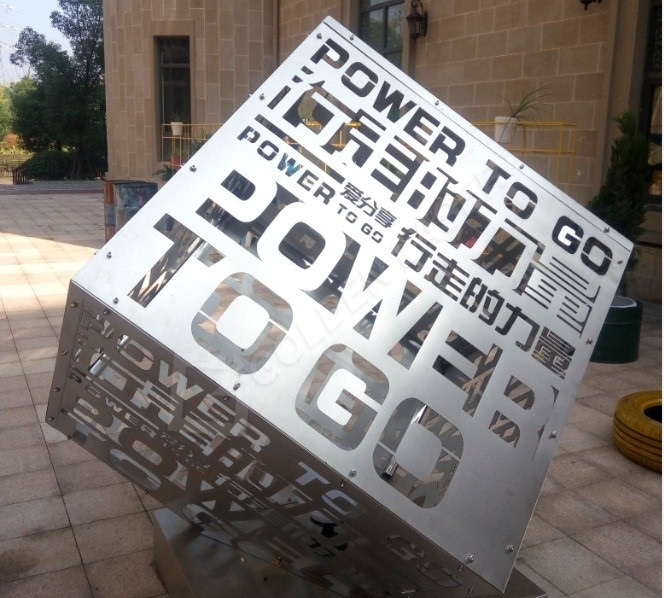

Insimbi engagqwali isetshenziswa kakhulu embonini yobunjiniyela bokuhlobisa ngenxa yokumelana kwayo nokugqwala okuqinile, izakhiwo eziphakeme zemishini, ukungaguquki kombala wesikhathi eside, kanye namathunzi okukhanya ahlukahlukene kuye nge-engeli yokukhanya. Isibonelo, ekuhlobiseni amakilabhu asezingeni eliphezulu ahlukahlukene, izindawo zokungcebeleka zomphakathi, nezinye izakhiwo zasendaweni, isetshenziswa njengempahla yamakhethini, izindonga zehholo, imihlobiso yamakheshi, izikhangiso zezimpawu, nezikrini zedeski langaphambili.

Kodwa-ke, uma amapuleti ensimbi engagqwali ezokwenziwa abe yimikhiqizo yensimbi engagqwali, kuwumsebenzi wezobuchwepheshe oyinkimbinkimbi kakhulu. Kudingeka izinqubo eziningi enqubweni yokukhiqiza, njengokusika, ukugoqa, ukugoba, ukushisela, nokunye ukucutshungulwa kwemishini. Phakathi kwabo, inqubo yokusika iyinqubo ebalulekile. Kunezinhlobo eziningi zezindlela zokucubungula zendabuko zokusika insimbi engagqwali, kodwa ukusebenza kahle kuphansi, izinga lokubumba liphansi futhi alivamile ukuhlangabezana nezidingo zokukhiqiza ngobuningi.

Okwamanje,insimbi engagqwali laser cutting imishiniasetshenziswa kakhulu embonini yokucutshungulwa kwensimbi ngenxa yekhwalithi yawo enhle yamapulangwe, ukunemba okuphezulu, ama-slits amancane, izindawo ezisikiwe ezibushelelezi, kanye nekhono lokusika ngokuguquguqukayo ihluzo ezingafuneki. Imboni yobunjiniyela bokuhlobisa nayo ayifani. Bheka ukusetshenziswa komshini wokusika insimbi engenasici embonini yokuhlobisa.