Wamkelekile kwi Golden Laser

Fumana eyona iLungileyo iLaser Tube Cutter

i Series

I-Intelligent "i" series yi-intelligent, digital and automated all-round-high-end laser pipe cutting machine.

I-2D kunye ne-3D ye-Laser yokusika intloko | Umlayishi wetyhubhu esetyenzisiweyo ophucukileyo | Inkqubo ye-MES iyahambelana

Uluhlu lweMega

I-MEGA series yi-3 kunye ne-4 chucks laser tube cutting machine

iphuhliselwe i-ultra-enkulu, inzima, kunye nemibhobho emide kunye neeprofayili zokusika.

Uqwalaselo oluguquguqukayo | Isakhiwo sokuxhoma ngecala | "0" Ukhetho lweTailer

S Series

I-Smart "S" i-series ultra-encinci ye-tube laser cutting machine

Ngokukodwa eyenzelwe iityhubhu ezincinci.

Inkqubo yokulawula ekrelekrele, ukucwangciswa kwetyhubhu encinci, ukondla ngokuzenzekelayo, ukusika, kunye nokubuyisela umva ukufezekisa ukusika okuphezulu kunye nokuchaneka okuphezulu kweetyhubhu ezincinci.

Umlayishi wetyhubhu woyilo oluqinileyo | Iqondo eliphezulu lokuzenzekela | isantya esiphezulu kunye nokuchaneka okukhulu

V Series

Umatshini wokusika we-laser encinci oqinisekileyo

Ukuphucula ukusebenza kakuhle kwemveliso.

Ukuseta iityhubhu encinci yokucofa ngokutya okuzenzekelayo, ukusika, kunye nokuqokelela. Oku kufezekisa ukusika ngokukhawuleza kunye nokuchanekileyo kweetyhubhu ezincinci.

Umlayishi wetyhubhu woyilo oluqinileyo | Iqondo eliphezulu lokuzenzekela | isantya esiphezulu

F Series

I-EcoFlex "F" ngumatshini wokusika umbhobho we-laser wezoqoqosho.

Ihlala ixesha elide kwaye isebenza ngokubanzi

Kulula ukusebenza | Uluhlu olubanzi lokucubungula | I-automatic kunye ne-semi-automatic tube loader

HP Series

Umatshini wokusika we-Beam laser

Ngokukodwa yenzelwe i-H beam, ndiyinqumle i-beam, isetyenziswe ngokubanzi kwisakhiwo kunye noshishino lwebhulorho.

Uyilo lweSakhiwo seBhulorho | Intloko yeLaser ye3D | Lungiselela Ubude

CELA INKCAZELO NGEENKCUKACHA EZINGAKUMBI

Konke okufuneka uyazi malunga nomatshini wokusika weLaser Tube ngo-2025

Umatshini wokusika i-laser ityhubhu yolunye uhlobo lomatshini wokusika i-fiber laser onqumla kuphela iityhubhu ezahlukeneyo zetsimbi kunye nemibhobho (insimbi engenasici, i-carbon steel, ubhedu, iProfayili ye-Aluminium),ihlukile kwiezinye izixhobo zokusika umbhobho, iakukho-ukuphathaindlela yokusika ephezulu echanekileyo, kunjaloakukho kugqwethekangexesha lemveliso.Kulula ukusikauyilo oluntsonkothileyokwityhubhu kunye nokuchaneka okuphezulu kwe-perforation yi-laser tube cutter.Kulula ukutshintsha uyilo lwakho lwemvelisoindlela kwi CNC isilawuli laser okrelekrele.CustomizedU-Chuck udibane neTube eyahlukileyo kunye noMdaniso weProfayili kunye nobunzima bokuqinisekisa isiphumo esikhulu sokusika iLaser

Yintoni iUncedo koomatshini bokusika iTubhu yeLaser?

1. Suti iiMibhobho ezininzi eziMilo

Round, Square, Rectangle, kunye neminye imibhobho ekhethekileyo Shaped, Channel Steel, I Beam, Profile, njalo njalo.

2. Ukugqojozwa okuFanelekileyo

Ukuchaneka okuphezulu malunga ne-0.1m, kulula ukusika naluphi na uyilo olunzima ngakumbi ukugqobhoza kumsebenzi wokusika umbhobho.

3. Akukho Uxinzelelo kwiMetal Surface

Ukusika i-Laser yindlela yokusika yobushushu obuphezulu, ayiyi kucinezela izinto, kwaye akukho ukuphazamiseka kwimveliso.

4. Umbhobho we-Welding Qaphela

Qaphela kwaye ugweme imigca ye-welding ukunciphisa ukuphuka ngexesha lokusika kwe-laser.

Laser Tube Cutting Machine Manufacturing

Amacandelo Angundoqo

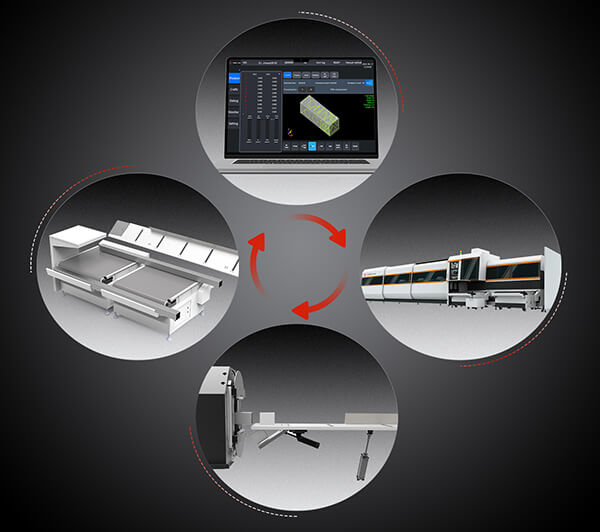

Usebenza njani umatshini wokusika umbhobho weLaser?

Umatshini wokusika umatshini we-laser ityhubhu ngokuyintloko unje.

1.Faka uhlobo lwetyhubhu kwisoftware ye-laser Nesting (Lanteck),

Misela iparameter yokuyila ngokufanelekileyo ngokobunzima betsimbi kunye nohlobo lwentsimbi, insimbi ethambileyo, insimbi engenasici, iAl, iBrass, njalo njalo.

2.Thumela ifayile kwisilawuli somatshini wokusika we-laser,

Yonke imilo esemgangathweni yeetyhubhu zetsimbi iya kubabonisa imilo ye-3D kwiscreen sokusebenza, unokuphinda ujonge uyilo ngokucacileyo ngakumbi.

3.Ukulayisha ityhubhu echanekileyo kumatshini wokusika ityhubhu ye-laser

Ngenkqubo yokulayisha ngokuzenzekelayo, akufanele ukhathazeke malunga netyhubhu engalunganga exutywe kunye nenqwaba yeetyhubhu, iyakulinganisa ngokuzenzekelayo okanye i-alamu ukuba awuzange ubeke umsebenzi wokusika umxube kwiprogram yokusika.

4.Qala ukusika kwaye uqokelele ityhubhu yesinyithi egqityiweyo.

Qinisekisa ukuba i-chiller yamanzi kunye ne-compressor yomoya ivuliwe ngaphambi kokucofa iqhosha elithi "qalisa", i-tailer yetyhubhu iya kulandela phantsi kwibhokisi yokuqokelela inkunkuma phantsi komzantsi womatshini, kwaye iindawo ezigqityiweyo ziya kuthumela kwitafile yokuhambisa kwibhokisi yokuqokelela.

Kutheni Khetha umatshini wokusika weSteel Laser Tube?

Iingqwalaselo Xa uthenga iLaser Tube Cutting Machine

1. Yintoni eyona Ukutyeba okuPhambili oKufunayo ukuSika?

Kubalulekile ukukhetha umatshini wokusika we-laser ochanekileyo we-laser ngenxa yokuba amandla ahlukeneyo e-laser ixabiso liya kuhluka kakhulu.

Khetha ngokobungakanani obukhulu, utyalo-mali luya kuhamba ngokulula kuhlahlo lwabiwo-mali lwakho.

2. Ngaba ufuna iMilo yeMibhobho yeMetal?

Kwityhubhu yesinyithi yemilo eqhelekileyo, kulula ukuyisika, njengengqukuva, isikwere, kunye noxande.

Ukuba imfuneko ukusika imibhobho ezimile, njenge Channel Steel, I beam, C uhlobo imibhobho kungcono ukukhangela kunye nengcali ukuqinisekisa kabini ukuba unako ngokusikwa.

3. Ngaba ufuna ukuQhagamshela ngeNkqubo yeERP okanye hayi?

Cinga ngemeko yakho yefektri kwaye ukhethe umlawuli we-laser ofanelekileyo uya kuba lukhetho oluhle.

Ukuba akukho mfuneko idibanisa iinkqubo ze-ERP kunye nabanye oomatshini bokugaya, isilawuli saseTshayina i-FSCUT iya kuba yinto efanelekileyo yokukhetha, i-interface enobungane kwaye kulula ukuyisebenzisa.

4. Ukuqondwa kweMfuno yeSicelo soShishino

Umatshini wokusika we-laser oluncedo wenzelwe ngokwemfuno eneenkcukacha zabathengi. Imisebenzi emininzi ilungiselelwe emva kokufunda nzulu iimfuno zemveliso yomthengi.

Oku kuhlangabezana nemfuno enokwenzeka kwaye kwenza lula kwaye kwandisa ukusebenza kakuhle komgca wemveliso.

Ubuchule obunamandla be-R&D bubalulekile xa ufumana abavelisi bomatshini wokusika ityhubhu yensimbi.

5. Umgangatho womatshini kunye namava eFactory

Ukubonelela ngomatshini wokusika we-laser wensimbi, umntu ufuna amava amahle kwindlela yokukhanya, indlela yombane, indlela yamanzi kunye ne-3D laser cutting technology. Ayizihlanganisi nje kunye.

I-Golden Laser ineminyaka engama-20 yamava ekuveliseni umgangatho omhle kunye nomatshini wokusika i-fiber laser tube, amava atyebileyo kunye ne-metal tube laser cutting machines, i-time-time after-service team ukuqinisekisa amava afanelekileyo omsebenzisi we-steel laser tube cutting machine.

6. Emva kokuthengiswa kweNkonzo

I-Golden Laser ithumela ngaphandle umatshini wokusika we-laser kumazwe angaphezu kwe-120 kunye nezixeko ezahlukeneyo.

Unokujonga umgangatho womatshini wethu kwindawo kwaye ujabulele umnyango nomnyango ngexesha emva kwenkonzo nge-arhente yethu okanye kumzi-mveliso ngokuthe ngqo. Sikwanayo neIziko leNkonzo ye-EuroeNetherlands

Singathanda ukusebenza nawe

Nceda usithumele umyalezo ukuba unayo nayiphi na imibuzo okanye izicelo kumatshini wokusika i-laser yensimbi.