Oomatshini bezolimo kunye nezixhobo zizixhobo eziyimfuneko zokuphucula ukusebenza kakuhle kwemveliso yezolimo, ukuqonda ukusetyenziswa kakuhle kwemithombo yendalo, kunye nokukhuthaza uphuhliso oluzinzileyo lwezolimo.

Ngophuhliso lwenzululwazi kunye nobuchwepheshe, oomatshini bemveli bezolimo kunye nezixhobo zokuvelisa izixhobo nazo zitshintshile ukusuka kwimisebenzi yezandla, imisebenzi yoomatshini, i-automation enendawo enye ukuya kwi-automation edibeneyo, ulawulo lwamanani, kunye nokusebenza kwezixhobo ezikrelekrele.

(Umgca wemveliso okrelekrele)

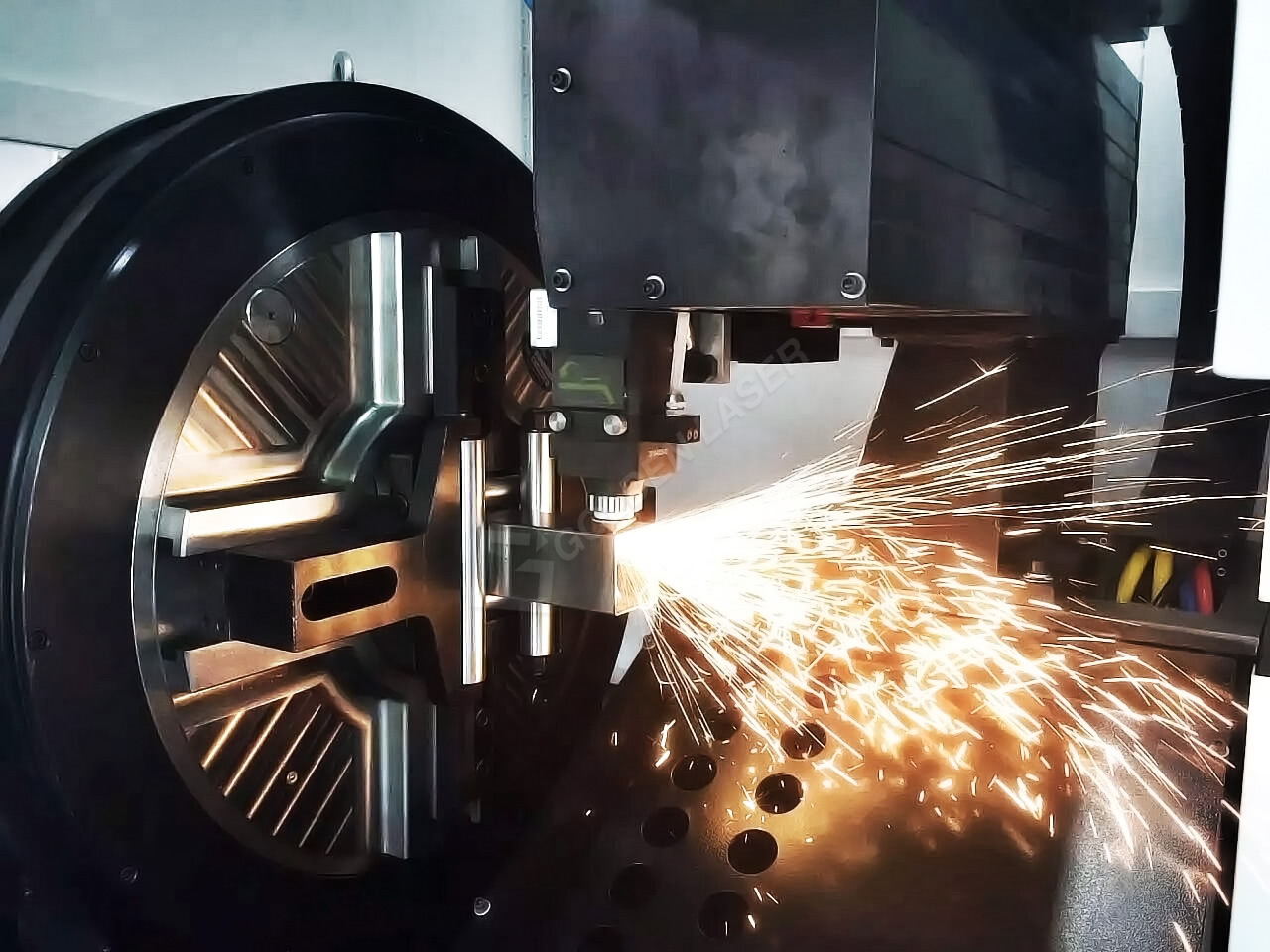

Okwangoku, iindibano zocweyo zale mihla zokwenziwa kwezixhobo zolimo zixhotyiswe ngemigca yendibano ezenzekelayo, imigca yepeyinti ye-electrophoretic kunye nezixhobo eziphambili ezinje ngomatshini wokusika we-laser, umatshini wokugoba we-CNC, kunye neerobhothi ze-welding.

Ekubeni uninzi koomatshini bezolimo basebenza kwindawo evulekileyo, enothuli, emanzi kwaye emdaka okanye emanzini, idibana nomhlaba, izichumisi, izibulala-zinambuzane, indle, izityalo ezibolayo kunye namanzi, ngoko ke ezi zixhobo kunye nokusingqongileyo ziya kutshabalalisa oomatshini. Ke ngoko, kwimveliso yoomatshini bezolimo, izinto zetsimbi kunye nezingezizo ezentsimbi ezineempawu ezinjengokumelana nokugqwala, ukumelana nokunxiba, ukunciphisa ukungqubana, ukuchasana kwempembelelo, kunye nokumelana nokukhathala kudla ngokusetyenziswa.

Indawo yomthengi yeGolden Vtop Laser-umbhobho laser ukusika umatshini P3080Akoomatshini bezolimo eFransi

IFiber Laser Cutting Tube Live-action

Njengoko sonke sisazi, izixhobo ze-laser zazisetyenziswa kakhulu kwiimoto kunye noomatshini bokwakha. Kutshanje, ziya zisanda iinkampani zoomatshini bezolimo, ngakumbi amacandelo kunye neenkampani zamacandelo ngokuthe ngcembe zithatha indawo yezixhobo ezikhoyo ukuze zifezekise ukusetyenzwa kwedijithali kuyo yonke imveliso, kwaye zithatha ubungcali, idijithali, i-automation, kunye nokuguquguquka njengomsebenzi wabo.

Njengomthengisi we-CNC fiber laser machine, i-Golden Vtop Laser umbhobho laser ukusika umatshiniisetyenziswe ngokubanzi kwimveliso yoomatshini basefama. Umatshini wokusika weLaser weLaser usebenzisa isoftware yoyilo ye-3D SOLIDWORKS, ayinakufezekisa uhlalutyo lwento enomda kunye nokulungiswa koyilo lwamandla esakhiwo semveliso, kodwa kunye nemveliso esemgangathweni yesakhiwo semveliso, iinxalenye, ukutywinwa, izinto, kunye neteknoloji yokucubungula njl. Ukongezelela, inkqubo yokutya ngokuzenzekelayo iyakwazi ukucubungula imithwalo yemibhobho kwaye yandise kakhulu ukusebenza kakuhle.

Umbhobho wokusika umatshini we-laser wokuvelisa umatshini wezolimo

Kuyaqondwa ukuba ukuqaliswa kwezixhobo ze-laser ezihlakaniphile azigcini nje ukunciphisa ubunzima bomsebenzi, kodwa kuphucula ukusebenza kakuhle kwemveliso. Ngaphambili, iinkqubo ezininzi kunye nenkqubo enzima zifuna ukungenelela ngesandla, kodwa ngoku zonke zinokugqitywa ngoomatshini. Ukongeza, ukusetyenziswa kwezixhobo eziphambili kuye kwanyusa ukuchaneka kokulungiswa kwamalungu kunye nomgangatho wokwenziwa kwemveliso, ngaloo ndlela kuphuculwa ngakumbi umgangatho woomatshini bezolimo, ukwanelisa iimfuno zabasebenzisi bokusebenza kwemveliso ngowona mlinganiselo mkhulu, kunye nokukhuthaza imveliso ekrelekrele koomatshini bezolimo.