Oomatshini bokusika iityhubhu yeLaser benza okungaphezulu kokusika iintlobo ngeentlobo zeempawu kunye nokudibanisa iinkqubo. Bakwashenxisa ukuphathwa kwezixhobo kunye nokugcinwa kwamalungu asele egqityiwe, nto leyo eyenza ukuba ivenkile isebenze ngokufanelekileyo. Nangona kunjalo, oku ayisosiphelo sayo. Ukwandisa imbuyekezo kutyalo-mali kuthetha ukuhlalutya ngononophelo ukusebenza kwevenkile, ukuphonononga zonke iimpawu zoomatshini ezikhoyo kunye nokhetho, kunye nokuchaza umatshini ngokufanelekileyo.

Kunzima ukucinga ukufikelela ekusikeni kwetyhubhu eyona ilungileyo-ukuba iindawo zokusebenza zingqukuva, isikwere, uxande, okanye ukumila kwe-asymmetrical-ngaphandle kweelases. Iinkqubo zeLaser ziyiguqule inkqubo yokusika iityhubhu, ngakumbi malunga neemilo ezintsonkothileyo. Umatshini onjalo ufuna utyalo-mali olubalulekileyo lokuqala, ngakumbi ukuba usebenza ngeesayizi ezinkulu zetyhubhu kwaye uzisa i-automation kunye nobunye ubuchwephesha obutsha kwinkqubo yokuvelisa, ke kuya kufuneka ucwangcise ngononophelo ukuze uqinisekise ukuba ukusika kwetyhubhu yelaser kuyabiza kakhulu kwinkampani yakho.

Ekugqibeleni, kufuneka uqwalasele izinto ezahlukeneyo ngaphambi kokuba uthathe isigqibo sokuthengaumatshini wokusika umbhobho we-laser; uyilo lwemveliso, ukwenza lula inkqubo, ukuncitshiswa kweendleko, kunye namaxesha okuphendula aphakathi kwezona zibalulekileyo.

Iimpawu zemveliso

Ukusika iLaser kunokuboleka kuyilo lwemveliso entsha ngokupheleleyo. Uyilo oluhlaziyiweyo noluntsonkothileyo kulula ukuluqhuba ngelaser kwaye lunokwenza imveliso yomelele kwaye ithandeke ngakumbi, ihlala inciphisa ubunzima ngaphandle kokuncama amandla. I-laser ye-tube igqwesa ekuxhaseni inkqubo yokuhlanganisa ityhubhu. Iimpawu ezikhethekileyo ze-laser-cut ezivumela iiprofayili zetyhubhu ukuba zigobe okanye zidityaniswe ngokulula zinokwenza lula ukuwelda kunye nokuhlanganisa kakhulu kwaye kuncede ukunciphisa iindleko zemveliso.

I-laser ivumela umqhubi ukuba anqumle imingxuma kunye ne-contours ngokuchanekileyo kwisinyathelo esinye sokusebenza, ukuphelisa ukuphatha inxalenye ephindaphindiweyo kwiinkqubo ezisezantsi (jonga uMfanekiso 3). Kumzekelo othile okhethekileyo, ukwenza uqhagamshelo lwetyhubhu ngelaser endaweni yokusarha, ukugaya, ukugrumba, ukugxothwa, kunye nokuphathwa kwezinto ezinxulumeneyo kunciphise iindleko zokwenziwa kweemveliso ngama-30 ekhulwini.

Ukucwangcisa ngokulula ukusuka kumzobo woyilo oncediswa yikhompyuter kwenza kube lula ukucwangcisa inxalenye ngokukhawuleza ukusika i-laser, nokuba yeyokuvelisa ibhetshi encinci okanye iprototyping. Ayisiyiyo kuphela i-tube laser process parts ngokukhawuleza, kodwa ixesha lokuseta lincinci, ngoko unokwenza iinxalenye nje-ngexesha ukunciphisa iindleko ze-inventory.

Ukutshatisa umatshini kwii-Aplikheyishini

Emva kokuthatha uluhlu lwamanyathelo akho okuvelisa aqhelekileyo, inyathelo lakho elilandelayo kukuphonononga iimpawu ezikhoyo kwaye uthathe isigqibo sokuba zeziphi na ezibalulekileyo.

Amandla okusika. Gcina ukhumbule ukuba i-laser ezininzi ze-tube zixhotyiswe ngee-resonators ezihambisa i-2 KW ukuya kwi-4 kW yamandla okusika. Oku kwanele ukusika ubukhulu obuqhelekileyo betyhubhu yentsimbi ephakathi (5⁄16 intshi) kunye nobukhulu obuqhelekileyo obuqhelekileyo be-aluminiyam kunye netyhubhu yentsimbi (¼ in.) ngokufanelekileyo. Abavelisi abasebenzisa izixa ezikhulu ze-aluminiyam kunye nentsimbi engatyiwayo baya kufuna umatshini kwindawo ephezulu yoluhlu lwamandla, ngelixa iinkampani ezisebenza ngentsimbi yokulinganisa ukukhanya ephakathi zinokuphumelela ngenye ekupheleni.

Umatshini wethu wokusika umbhobho we-laser P3080 3000w wokucutshungulwa kweetyhubhu e-Australia

Umthamo. Umthamo womatshini, odla ngokulinganiswa ngokobunzima bobunzima ngenyawo, yenye into ebalulekileyo ekufuneka iqwalaselwe.

Iityhubhu ziza kwiindidi ezahlukeneyo zobukhulu obuqhelekileyo, ngokuqhelekileyo ukusuka kwi-20 ukuya kwi-30 yeenyawo kwaye ngamanye amaxesha ubude. Umenzi wesixhobo soqobo okanye umenzi wekhontrakthi uyala ityhubhu ngokwesayizi ngokwesiko ukunciphisa i-scrap kwaye ke kufuneka athathele ingqalelo umatshini ohambelana nobukhulu bezinto eziqhelekileyo. Ukhetho luba nzima ngakumbi kwiivenkile zemisebenzi. Iityhubhu ezisuka kwindawo yokusila ziqhele ukuba yi 24 ft ubude bobude ukuya kuthi ga kwi 6 phakathi kunye ne 30 ft ubude kwiiprofayile ukuya kwi 10 ubukhulu. Kolu luhlu lobungakanani, ubunzima obuqhelekileyo benkqubo ye-laser ityhubhu inokuya kuthi ga kwi-27 yeekhilogram ngonyawo lomgca.

Umthwalo wezinto eziphathekayo kunye nokuThuthulwa. Enye into ekukhetheni umatshini kukukwazi ukondla kwizinto eziluhlaza. Umatshini welaser oqhelekileyo, ukusika iindawo eziqhelekileyo, ubaleka ngokukhawuleza kangangokuba iinkqubo zokulayisha ngesandla azikwazi ukuqhubeka, ke oomatshini bokusika i-tube laser beza ne-bundle loader, elayisha iinyanda ukuya kuthi ga kwi-8,000 lbs. yombandela kwiphephancwadi. Umlayishi uyahlula iityhubhu kwaye azilayishe nganye nganye kumatshini. Isilayishi senqwaba sinokuzisa inani letyhubhu ekrwada kwimagazini ye-buffer ukunciphisa amaxesha okulayisha phakathi kwetyhubhu ukuya kwimizuzwana eyi-12. Ukutshintsha ukusuka kwisayizi yetyhubhu ukuya kwesinye kwenziwa lula ngomatshini ozenzekelayo ngaphakathi komlayishi. Zonke izilungiso ezifunekayo kwisayizi entsha yetyhubhu ziphathwa ngumlawuli.

Xa kuyimfuneko ukuphazamisa imveliso enkulu yomsebenzi omncinci, kusebalulekile ukuba ubenokhetho lomthwalo owenziwe ngesandla. Umsebenzisi unqumamisa ukusebenza kwemveliso, alayishe ngesandla kwaye aqhubekise iityhubhu ukugqibezela umsebenzi omncinci, emva koko aqalise ukusebenza kwemveliso. Ukothula kwakhona kuyasebenza. Icala lokukhupha izixhobo zeetyhubhu ezigqityiweyo ngokuqhelekileyo zi-10 ft ubude kodwa zinokunyuswa ukuze zifake ubude beengxenye ezigqityiweyo ukuba zicutshungulwe.

Ukufunyanwa kwe-Seam kunye neMilo. Iityhubhu ezidityanisiweyo zisetyenziswa kwiimveliso ezenziweyo ngaphezulu kweityhubhu ezingenamthungo, kwaye i-weld seam inokuphazamisa inkqubo yokusika i-laser kwaye mhlawumbi indibano yokugqibela. Umatshini we-laser oxhotyiswe nge-hardware efanelekileyo ngokuqhelekileyo unokubona i-welded seams ukusuka ngaphandle, kodwa ngamanye amaxesha ukugqiba kwetyhubhu kufihla i-seam. Inkqubo eqhelekileyo yokuva umthungo isebenzisa iikhamera ezimbini kunye nemithombo yokukhanya emibini ukujonga ngaphandle nangaphakathi kwityhubhu ukubona i-weld seam. Emva kokuba inkqubo yombono ibone i-weld seam, isoftware yomatshini kunye nenkqubo yokulawula ijikelezisa ityhubhu ukunciphisa impembelelo ye-weld seam kwimveliso egqityiweyo.

Uninzi lweenkqubo zelaser ityhubhu zinokusika ezingqukuva, isikwere, kunye netyhubhu exande, kunye neeprofayili ezinjengeemilo ze-teardrop, intsimbi ye-engile, kunye ne-C-channel. Iiprofayili ze-Asymmetrical zinokuba ngumngeni ukulayisha kunye nokubambelela ngokufanelekileyo, ngoko ke ikhamera ekhethiweyo enezibane ezikhethekileyo ihlola ityhubhu ngexesha lokulayisha kwaye ilungise i-chuck ngokweprofayili efunyenweyo. Oku kuqinisekisa ukulayishwa okuthembekileyo kunye nokusikwa kweeprofayili ze-asymmetrical.

Ukusika Intloko. Ukusika iBevel kubalulekile ukudibanisa iityhubhu ezisikiweyo ukuze zidibanise. Ukusika i-bevel kufuna intloko yokusika ethambekela ukuya kuthi ga kwi-45 degrees kulo naliphi na icala ngexesha lokusika. Ukhuseleko olongezelelweyo lokucutshungulwa ngexesha lenkqubo yokusika i-bevel, intloko yokusika inokukhuselwa ngamamagnethi. Kwimeko yongquzulwano phakathi kwe-tubular workpiece kunye nentloko, intloko iyahlukana; inokuphinda iqhagamshelwe kwimizuzwana embalwa. Kwakhona kunokwenzeka ukudibanisa intloko yokusika i-bevel kunye ne-axis eyongezelelweyo ye-high-speed axis yokuphucula ukukhawulezisa ukusika, ukuvumela ukwanda kwemveliso yezixhobo ezisondela kwi-30 ekhulwini.

Ukwandisa ukusebenza kakuhle

Emva kokuchonga ixabiso inkqubo yokusika i-laser tube inokuzisa kwinkqubo yokuvelisa, kufuneka uqwalasele ezo zixhobo zesicelo sakho. Umzekelo, imfutshane kakhulu kwinkqubo yokulayisha inokuchaphazela kakhulu ukusebenza kwendlwane yeendawo ezigqityiweyo, nto leyo eyandisa inkunkuma, ngelixa ixesha elide lenkqubo lingafuna utyalo-mali oluphezulu kunye nesithuba somgangatho esingaphezulu kuneso sifunekayo. Ukongeza ekufuneni iingcebiso kubavelisi benkqubo, kuya kufuneka ukuba usike iisampulu zesampulu kwaye uvavanye lonke ukhetho olukhoyo ukuze uqinisekise ukuba utyalo-mali lwakho lufumana eyona mbuyekezo ingcono.

Umbhobho weLaser Cutter kwisiza sethu soMthengi

IFiber Laser Tube Pipe Cutter 3000W P3080 yeFayibha yeLaser yokulungisa imibhobho eFransi

I-Automotic Bundle Loader Fiber Laser Pipe Cutting Machine P3080A e-USA

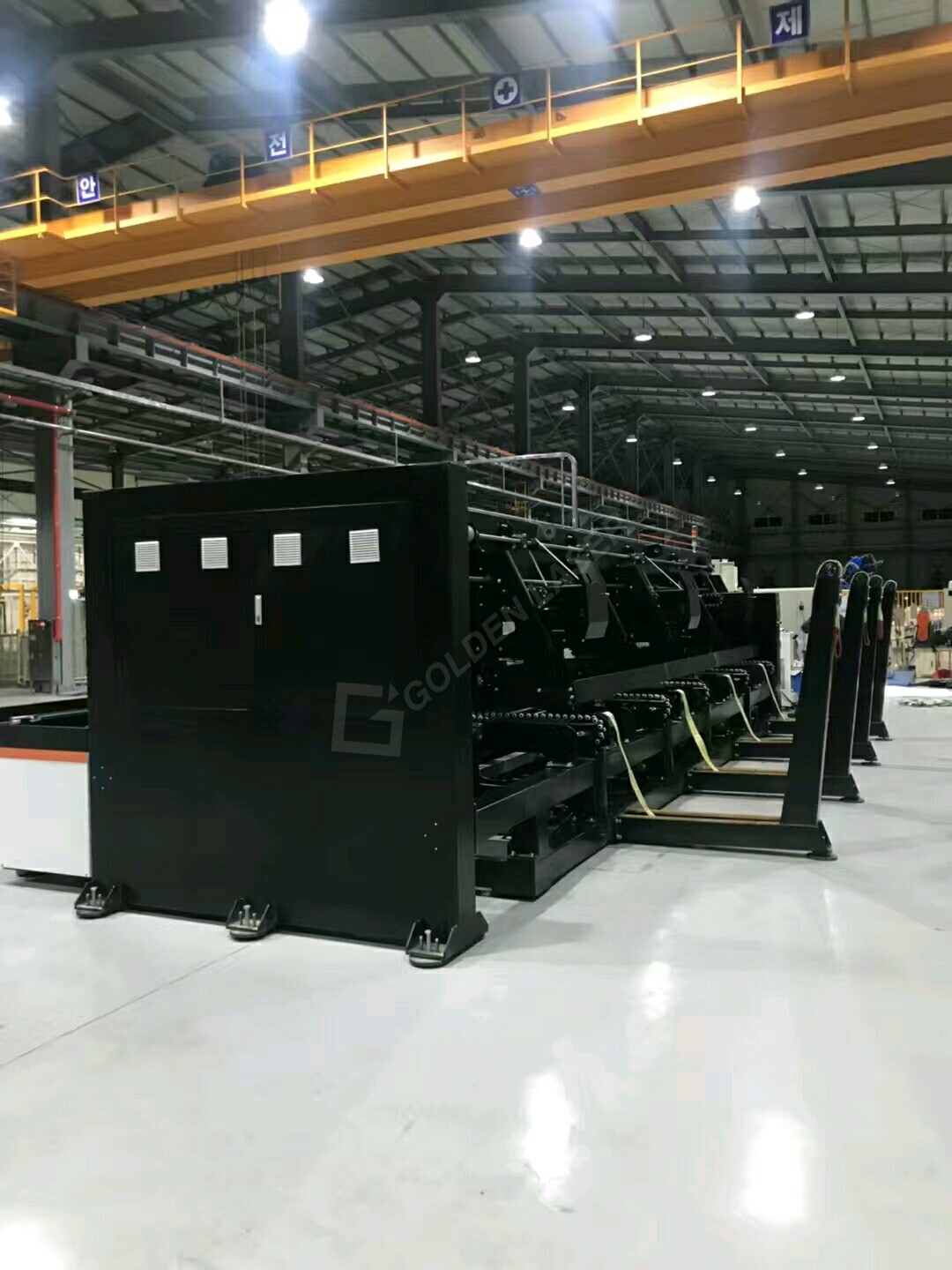

Iiseti ezine Umbhobho Laser Cutter P2060A For Metal Ifenitshala eKorea

I-Tube Laser Cutting Machine P2060A yokuLungiswa kwemibhobho eMexico

Umbhobho wokusika umatshini weLaser P3080 woLungiso lwemibhobho eFransi

I-Cover egcweleyo ye-Cnc yoBuchule boMbhobho wokusika umatshini weLaser P2060A eTaiwan

IFayibha yoMbhobho yeLaser Cutter eyenziwe ngokwezifiso iP2080A eKorea

I-P30120 ye-Metal Tube Laser Cutting Machine yeSteel Structure e-China