Umonakalo wemitha yase-laser ukuya emzimbeni womntu kubangelwe yi-Inder ye-Laser ye-Laser kunye nefuthe le-PhotoSchemical kunye ne-Skins ye-Hazard yeNdawo eyiNkqubo echaziweyo echaza inqanaba le-laser emzimbeni. Kukho amabanga amane, i-laser esetyenziswe kumshini wokusika i-fiber ser yeklasi yeklasi iv. Ke ngoko, ukuphucula ukukhuselwa koomatshini hayi kuphela indlela yokhuseleko kuphela kubo bonke abasebenzi abafuna ukufikelela kolu hlobo loomatshini, kodwa banoxanduva kwaye bahlonele abasebenzi abasebenza lo matshini. Ngoku i-laser yamandla e-fiber Laser ye-fiber Laser iphakama kwaye iphakame, ukusuka kumatshini wokusika i-500w kwi-15000w ye-Short ukuya kwi-15000w yokufumana amanzi, ukukhula ngokukhawuleza kwe-laser kwenza ukuba i-laser ibaluleke ngakumbi.

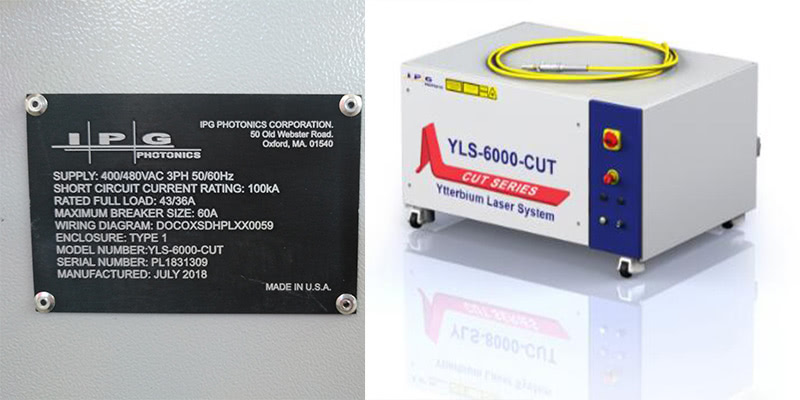

I-6000W IPG Leser

Wasekwa ngo-1992, iGolden Laswer ijolise kwimveliso yase-laser, kwaye idibene noyilo lwemveliso yase-laser, ukuvelisa, ukuthengisa kunye nenkonzo yemveliso yokuqala yemveliso, umbono wokhuseleko wokuqala wadinwa. IOkufakwe kwi-Pallet yeTheyibhile yeThelitha ye-fiber lamer yokutyibilikayasungulwa kule nto.

Amagqabantshintshi oMatshini oQhelekileyo ofakwe kwi-Fiber Laser

Uyilo oluvaliweyo oluvaliweyo luqinisekisa ukuqaphela ngokukhuselekileyo kwenkqubo yokusika

Njengoko ubona emfanekisweni apha ngasentla, ukhuselekile ngokupheleleyo xa umi phambi kwale ndawo ifakwe kwitafile yetafile ye-fiber yase-fiber lamer cute. Okwangoku, ukwenzela ukugcina i-laser enqumlayo ngexesha lokwenyani, iifestile zokujonga zenziwe ngaphambili kunye necala lomatshini. Ifestile yokujonga isebenzisa imigangatho ephezulu yecandelo leglasi yokunganyangeki yemitha, kwaye iwindow inkulu ngokwaneleyo ukuba ubone inkqubo yokusika. Nokuba awunayo iiglasi zokhuseleko se-laser, unokufumana i-"illy ngokukhuselekileyo "ubuhle" be-laser.

Umatshini wokusika i-fiber lamer kunye netafile yokutshintshiselana

Ikhamera yekhamera ye-2. Ikhamera ibeka iliso lokusika kwi-cuted kwixesha lokwenyani

Inqaku lesibini lolo matshini kukuba sifake ikhamera yenkcazo ephezulu kwi-angle egqibeleleyo ngaphakathi kwendawo evalelweyo yokuqinisekisa ukuba umqhubi unokugcina inkqubo yokusika i-laser ngokucacileyo ngelixa isebenza ngomatshini. Okwangoku, ikhamera iya kuzisa isikrini esicacileyo nesingayilibaziweyo sokujonga kwitheyibhile yokusebenza, ke umqhubi unokwazi umatshini ngaphakathi nokuba usebenza ngomatshini. Ukuba izixhobo zinemodeli engaqhelekanga, umqhubi unokusingatha ngokufanelekileyo okwesihlandlo sokuqala ukunqanda ilahleko engaphezulu.

Ingqokelela yoMatshini oPhezulu woPhuculo wothuli kunye nokuqokelelwa kweSmog

I-3.Machine yenkqubo ye-ventilation ephezulu yenza ukhuseleko lwendalo

Ngexesha lenkqubo yokucheba i-laser, ngakumbi xa usike iqhekeza lekhabhoni kunye nentsimbi engenasibala, iya kuvelisa umsi onamandla nothuli. Ukuba akunakwenzeka ukuba ukuphelise le nkuni kunye nothuli ngexesha elifanelekileyo, isixa esikhulu somsi esiqokelela ngaphakathi kumatshini siya kubangela umatshini xa ungoyena mntu ukhathazekileyo. Ngenxa yoko, sasiyiqwalasele ngoyilo lomatshini. Uthuli olusikiweyo kunye nomsi luvuthelwa yigesi ekusikeni, kuyakusasazeka ngeendlela ezahlukeneyo kunye nemikhombandlela, kodwa uninzi lwayo luya kugxila kumbindi womatshini. Ngokwentshukumo kunye nokuhamba komsi, umatshini wenziwe ngenkqubo ephezulu yokukhupha. Imingxunya yokuqokelela uthuli isasazwe kumatshini ongaphezulu kweefestile ezininzi kunye nolwabiwo, kwaye umatshini uxhotywe ngenjini enkulu yomoya. Ke ngoko, kwinyani yokwenyani, ifuthe lokuqokelela uthuli lilungile.

Nje ukuba uqonde ngokupheleleyo itafile yethu efakwe kwi-Pheber ye-Pheber yeFuber Laser Laser, kuya kufuneka ukwazi ukuqonda ukuba inokukunceda wenze ixabiso ngokukhuselekileyo ngelixa usebenza ngokufanelekileyo.