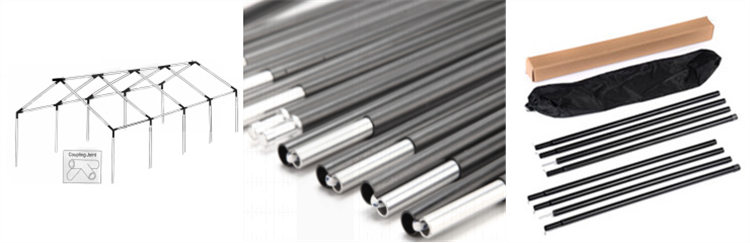

Iintente ze-Stent zisebenzisa iifom zesakhelo, ziquka i-stent yesinyithi, i-canvas kunye ne-tarpaulin. Olu hlobo lwentente lulungele ukugquma isandi, kunye nokuqina okulungileyo, ukuzinza okuqinileyo, ukugcinwa kobushushu, ukubumba ngokukhawuleza kunye nokubuyisela. Izitenti zizixhaso zentente, yayidla ngokwenziwa ngentsimbi yeglasi kunye ne-aluminium alloy, ubude bestente busuka kwi-25cm ukuya kwi-45cm, kunye nedayamitha yepali exhasayo yi-7mm ukuya kwi-12mm.

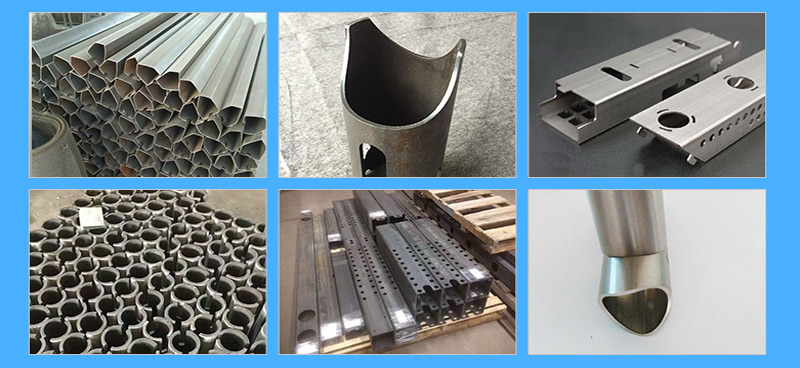

Kutshanje, sifumene umthengi obesebenzela imveliso yeentente zangaphandle, wandwendwela umzi-mveliso wethu. Ukusuka kumthengi, besisazi ukuba ukuveliswa kweentente ze-stent kufuna iinkqubo ezininzi, ezifana ne-pipe sawing, i-lathe processing, i-punch yemingxuma kunye ne-drill, umbhobho we-TIG welding njl.

Okokuqala, idinga umatshini wokusarha wokunqunyulwa kombhobho, ukusika kufuneka kuhambelane nomzobo kwaye kufuneka kususe i-burrs ebukhali ngesandla.

Okwesibini, ihamba kunye nokulungiswa kwe-lathe yokusika i-chamfer kunye nokususa imingxuma yangaphakathi okanye yangaphandle.

Okwesithathu, emva kokunqunyulwa, idinga umatshini wokubhoboza kunye nokugrumba kwimingxuma ye-punch kunye ne-drill njl.

Okwesine, umbhobho kwakufuneka udityaniswe kunye, kwaye isityalo sifuna ileyibhile yokuncamathisela ukuphawula yonke imibhobho ngokulandelelana kwayo.

Emva kwazo zonke ezi nkqubo, umzi-mveliso ufumana i-stent. Kodwa idinga iiseti ezininzi zokusarha, ukugqobhoza, oomatshini bokomba, kodwa ikwafuna abasebenzi abaninzi kakhulu.

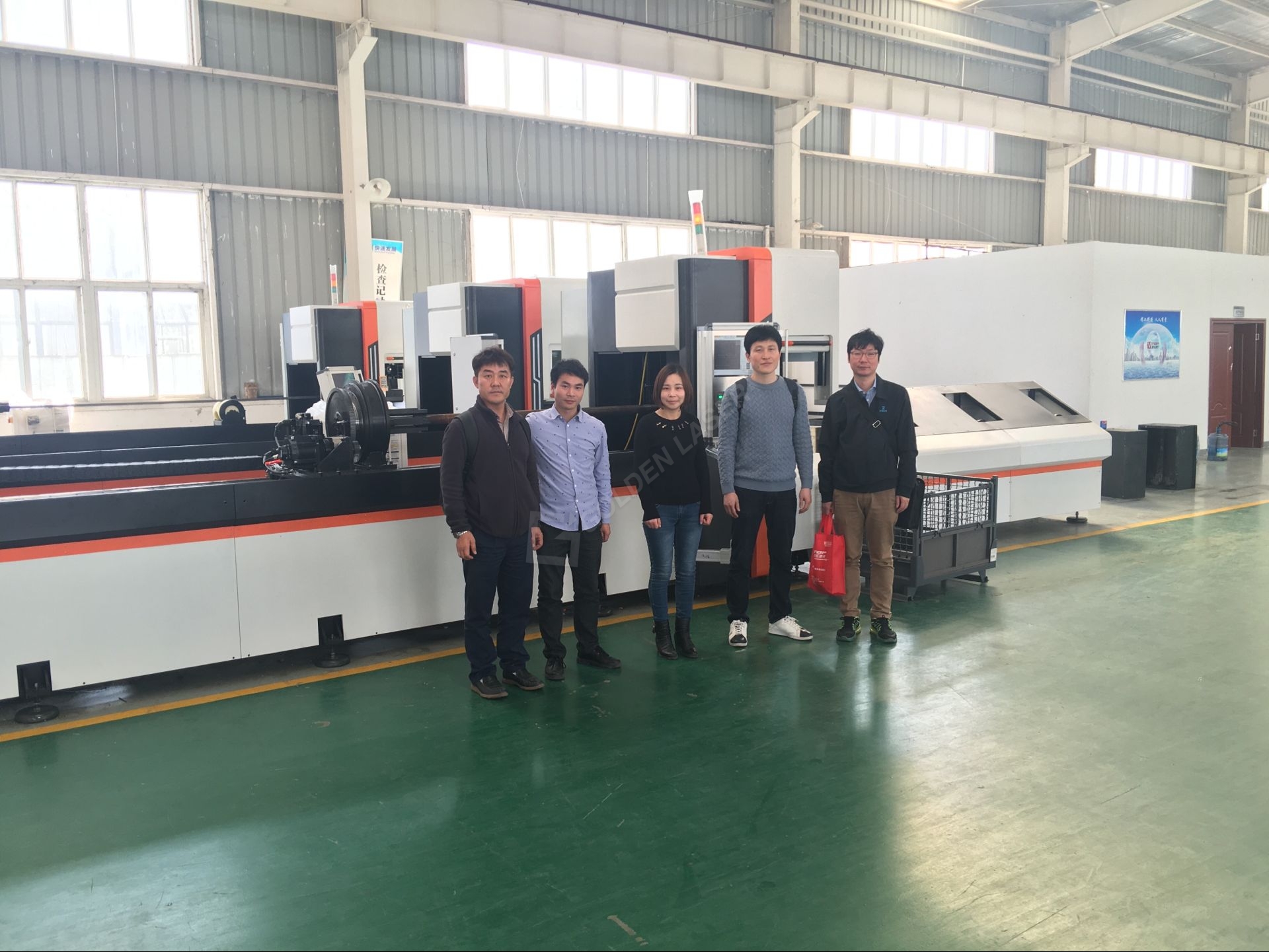

Ukuze kuphuculwe ukusebenza kakuhle kwemveliso kunye nokulungelelanisa iimfuno zemveliso yanamhlanje, umthengi wenza uphando oluninzi lweemarike, ekugqibeleni baqhagamshelana ne-laser yegolide kwaye bafuna ukwazisa umatshini we-GOLDEN-VTOP LASER welding.

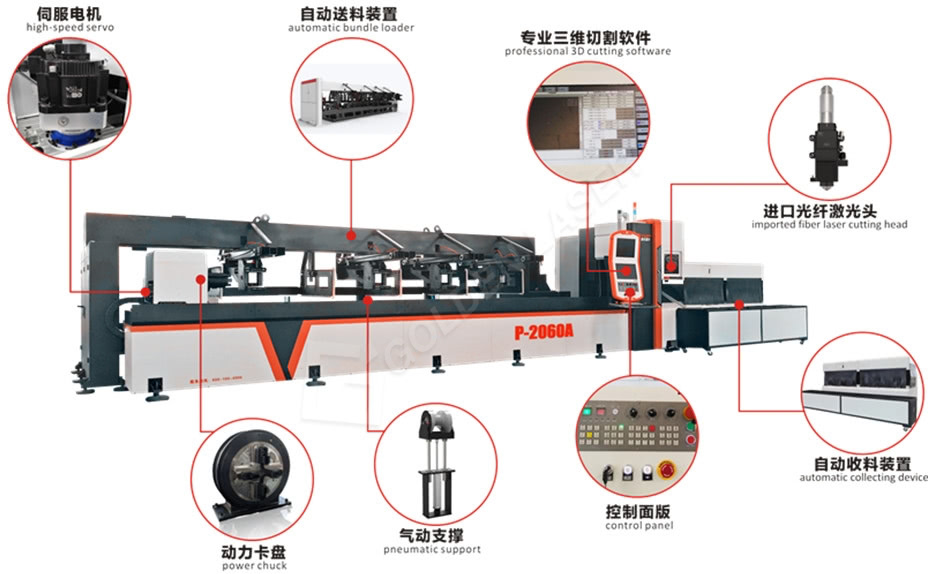

Umatshini wokusika we-Golden Vtop we-laser we-laser ufanelekile kuzo zonke iintlobo ze-tube okanye ukusika umbhobho, unokuqhuba umbhobho okanye ubude betyhubhu ye-6m, 8m kunye ne-12m, kunye nobubanzi be-10-300mm. Ngoku isetyenziswe ngempumelelo kumashishini afana nokucutshungulwa kombhobho, izixhobo zokufaneleka, ifenitshala yentsimbi, i-chassis yemoto, i-showcase kunye neshelufa, ukwakhiwa njl njl.

Kwaye inoncedo olulandelayo:

1. Gcina abasebenzi kunye nendawo yomgangatho

Ngenxa yokuba umatshini wokusika umbhobho we-laser unokunciphisa oomatshini be-punch 3-4, oomatshini bokugaya i-1-2, i-1-2 i-abrasive saw abrasive. Ngaloo ndlela igcina indawo yomgangatho wee-workshops ze-1-2 kunye neendleko zabantu malunga nabantu aba-7. Nciphisa inyathelo lokucubungula kwaye ugcine ixesha.

Umbhobho wokusika umatshini we-laser unokufezekisa ukumakisha okuzenzekelayo, ukusika kwe-CNC kunye nokwenza ngexesha elinye, ifanele zonke iintlobo zombhobho kunye neemfuno zokusika (ukunqunyulwa, i-beveling, i-slotting, i-drilling, ukusika iintyatyambo), kwaye indawo yokuphela kokusika i-sooth ngaphandle kwe-deburring kunye ne-black-edged.

2. Ukugcina izixhobo

I-laser cutter yombhobho ingabala ngokuzenzekelayo ukucwangciswa kunye neendlela zokusika, phantse akukho nkunkuma yezinto. Akukho xhulumaniso oluthe ngqo phakathi kwentloko yokusika kunye nodonga lombhobho, ngoko ke isiphelo sokusika sihamba kakuhle kwaye singenasiphelo esimnyama, akukho deformation yeemveliso ezigqityiweyo kwaye phantse akukho lahleko.

3. Ukuchaneka okuphezulu

I-laser yegolide yombhobho we-laser cutter inokufuna ngokuzenzekelayo umphetho kwaye wenze ulungiso, nokuba kunqunyulwa ixesha elide, isaqinisekisa ukuchaneka kunye nokuhambelana kwemveliso egqityiweyo. I-chuck inokulungelelaniswa ngokuzenzekelayo kwaye ifakwe, kunye nokukhulula ngokuzenzekelayo, kuphelisa impembelelo eyenziweyo kwimveliso egqityiweyo.