1. Ithini iSkicon Sheet?

Iphepha le-Silicon Stees elaziwa ngabaqhamishino liqhele ukuba laziwa njengephepha lensizi yensico. Luhlobo lwe-ferrosilicicicicicicicicicicicicicicicicicicicicicicicicicicicic alloy ebandakanya ikhabhoni esezantsi kakhulu. Ngokuqhelekileyo iqulethe i-0.5-165% ye-silicon kwaye iqengqele ubushushu kunye nokubanda. Ngokubanzi, ubukhulu bungaphantsi kwe-1 mm, ngoko ibizwa ngokuba yiplate encinci. Ukongezwa kwesilika Ukonyusa ukunyangwa kwentsimbi kwaye ukwenziwa kwe-gesic ye-manic, ukunciphisa ukunxibelelana, ilahleko ephambili (ilahleko yentsimbi (ilahleko yentsimbi) kunye nokwaluphala kwentsimbi.

Iphepha le-silicon lisetyenziselwa ukwenza i-cores yentsimbi yabaqeqeshi abahlukeneyo, iimotors kunye nabavelisi.

Olu hlobo lwephepha le-silicon yensizi lunepropathi ebalaseleyo ye-electromagnetic, yindawo ebalulekileyo kwaye ibalulekile emandleni, unxibelelwano kunye nemizi-mveliso yesixhobo.

2. Iimpawu zephepha lesilika

A. Ukuphulukana kwentsimbi yentsimbi yeyona nto ibalulekileyo yomgangatho. Onke amazwe akwilizwe liqulunqa ilahleko yentsimbi njengenqanaba, iphantsi ilahleko yentsimbi, inqanaba eliphakamileyo, kwaye lingcono umgangatho.

B. Ukungeniswa kwemagneti ephezulu. Ngaphantsi kwentsimi efanayo ye-magnetic, iphepha lesiliven lifumana ubume obuphezulu bemagnethi. Umthamo kunye nobunzima be-motor kunye ne-iron yentsimbi yentsimbi eyenziwa yi-Silicon Sheet inciniba kwaye ukukhanya, oko kungasindisa ubhedu, izixhobo zokuthambisa.

C.Iger. Ngomgangatho ogudileyo, iflethi kunye ne-idilick, iphepha lensizi le-silicon linokuphakama phezulu.

D.Umphezulu une-adhesion elungileyo kwifilimu efakwe ifilimu kwaye ilula yokwehla.

I-3. Isilicon ye-selicon ye-Steee Story

Ubukhulu bezinto ezibonakalayo: ≤1.0mmm; Isifundo esiqhelekileyo se-0.35mm.5mm.65mm;

Probes: I-Ferrosilicicon Allowy

➢ Iimfuno zemifanekiso: Ivaliwe okanye ayivalwanga;

➢ Iimfuno zokuchaneka: IBakala 8 ukuya kwi-10 ukuchaneka;

I-Glitch Edement Senments: ≤0.0mm;

I-4.

Ukucheba: Ukucheba yindlela yokusebenzisa umatshini wokucheba okanye isikere. Ubume bemisebenzi esebenzayo ngokubanzi ilula kakhulu.

➢ Ukuphoswa: Ukuhlaba i-punching: Ukutsalwa kubhekisa ekusebenziseni iimbumbulu zokuthintela, ukusika imingxunya, njl njl njl. Kwaye inokutsala iimbumbulu zokuthintela zonke iintlobo zephepha lesilika.

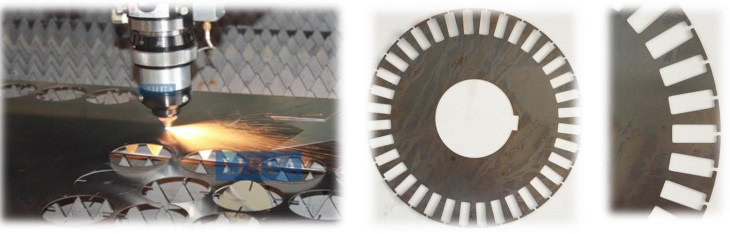

Ukunqunyulwa: Sebenzisa umatshini wokusika i-laser ukusika zonke iintlobo zokusebenza. Kwaye ngokuthe ngcembe ukuba yindlela eqhelekileyo yokusika iqhubekisi iphepha lesilivere.

Ii-sperchrating: Kuba i-chip ye-chip ye-iron ichaphazela ngokuthe ngqo intsebenzo ye-translamer, ke ukuba umkhuhlane we-burr ungaphezulu kwe-0.03mm, kufuneka ityunyuzwe ngaphambi kokupeyinta.

Ukupeyinta: Umphezulu we-iron chip uya kupeyintwa ngefilimu eqinileyo, ubushushu kunye ne-rust-rust-rust-rust-rust-rust.

➢ Ukutyume: Ipeyinti yephepha le-Silicon Stees kufuneka yomiswe kwiqondo lobushushu oluthile kwaye emva koko lomelele kwi-hard, eyomeleleyo, ifilimu egudileyo.

I-5. Inkqubo yokuthelekisa - Ukusika i-laser

Ukusika i-laser: Izinto zibekwe kwitheyibhile yomatshini, kwaye ziya kunciphisa ngokwenkqubo ebekiweyo okanye igraphic. Ukusika i-laser yinkqubo ye-thermal.

Izibonelelo zenkqubo ye-laser:

➢ Ukuguquguquka okuphezulu, unokulungiselela imisebenzi yokulungisa nangaliphi na ixesha;

Ukuchaneka okuphezulu, ukulungiswa okuqhelekileyo koomatshini yi-0.01mm, kunye nomatshini wokusika i-lall echanekileyo yi-0.02mm;

Ungenelelo oluncinci lwentsulungeli, kuya kufuneka ucwangcise iinkqubo kunye neeparamitha zenkqubo, emva koko uqale ukuqhubekeka kwiqhosha elinye;

➢ Ungcoliseko lwengxolo alubonakali;

➢ Iimveliso ezigqityiweyo azikho ngaphandle krward;

➢ Umsebenzi wokuSebenza unokuba lula, untsonkothileyo kwaye unendawo yokulungisa engenamda;

Umatshini wokusika i-laser ilondolozo simahla;

➢ usebenzisa indleko;

➢ Izixhobo zokonga, ungasebenzisa umsebenzi wokwabelana ngomda ngesoftware ye-ndling ukufezekisa ulungiselelo olululo lwemisebenzi, kwaye unyuse ukusetyenziswa kwezixhobo.

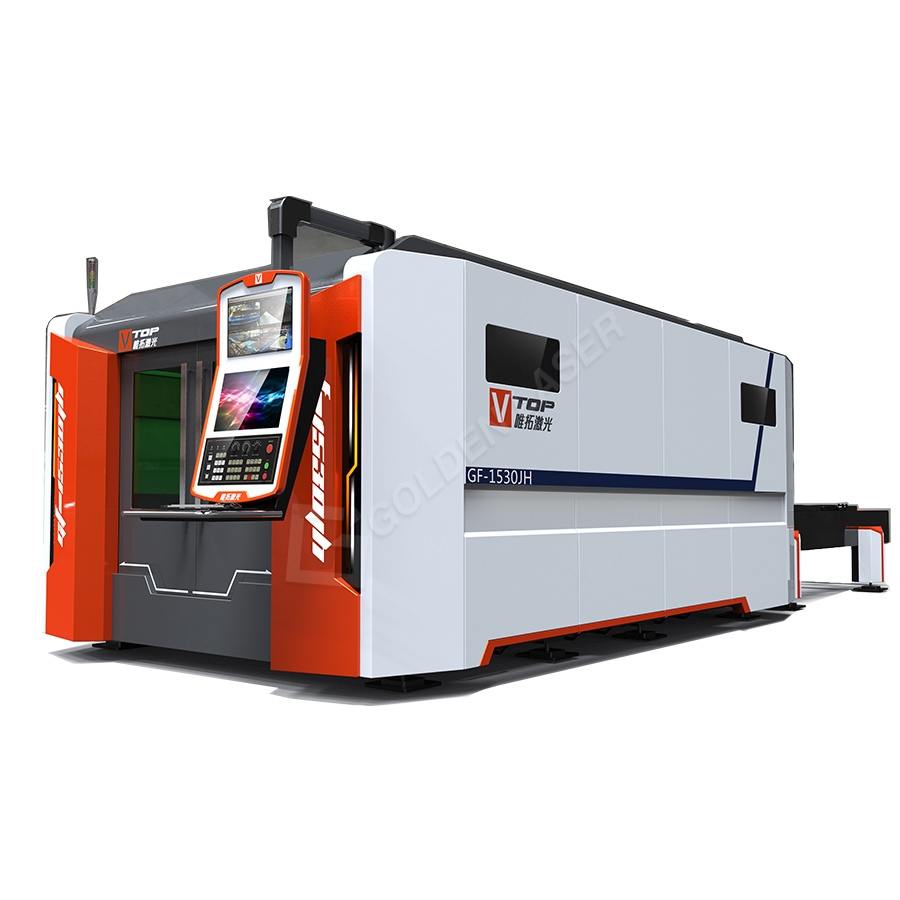

I-6. I-Laser yokusika izisombululo

Uhlobo oluvulekileyo lwe-1530 fiber Laser i-gf-1530 i-certion ye-gf-6060 i-GF-6060 evaliweyo yetafile ye-GF-1530JH