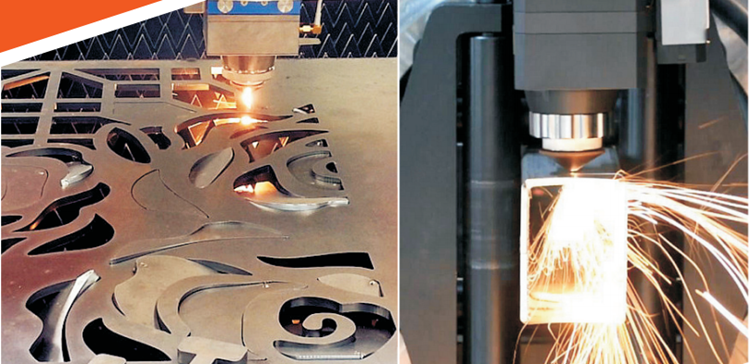

Imisebenzi yokwenza i-laser ngoku ibandakanya ukusika, i-welding, ukunyanga i-head, i-valing, ukubhukisha, ukungcungcutheka, ukungqubana, kunye nokuzonwabisa. Iinkqubo zemveliso ye-laser ikhuphisana ngokweetekhnoloji kwaye zoqoqosho ezinenkqubo yokwenziwa kwezemveliso eziqhelekileyo nezomatshini, i-thermal womatshini, i-EDM), i-EdMAMIL RIT, i-Plasma yokusika.

Ukusika kwamanzi i-jet yinkqubo esetyenziselwa ukusika izinto ze-jet ngamanzi amachaphaza angama-60,000 kwi-intshi nganye yesikwere (PSI). Rhoqo, amanzi axutywe ne-gasa i-garnet eyenza ukuba izinto ezininzi zinqunywe ngokucocekileyo ukuvala ubungqingqwa, ngokucekeceke kunye nokugqitywa komda. Iijethi zamanzi ziyakwazi ukusika izinto ezininzi zemizi-mveliso kubandakanya intsimbi engenasitali, i-indel, i-titanium, i-aluminium, isixhobo se-ceimic, i-ceramia, neplate yesixhobo. Le nkqubo ivelisa ingxolo enkulu.

Itheyibhuli elandelayo iqulethe uthelekiso lokusika intsimbi usebenzisa inkqubo yokusika i-CO2 ye-CO2 kunye nenkqubo yokusika kwamanzi kwi-jet ye-jet yendawo yemizi-mveliso.

§ Izenzo ezisisiseko zenkqubo

§ Inkqubo yesiqhelo yenkqubo kunye nokusetyenziswa

§ Ukutyalomali kokuqala kunye neendleko zokusebenza

§ Ukuchaneka kwenkqubo

Ukuqwalaselwa kukhuseleko kunye nendawo yokusebenza

Inkqubo yenkqubo esisiseko

| Isifundo | I-co2 laser | Ukusika kwamanzi |

| Indlela yokudlulisela amandla | Ukukhanya kwe-10.6 m (uluhlu olude kakhulu) | Amanzi |

| Umthombo wamandla | I-laser yegesi | Impompo yoxinzelelo oluphezulu |

| AMANDLA kangakanani | I-Beam Ikhokelwa zizibuko (iipliksi eziphaphazelayo); I-fiber-sosulo inokwenzeka kwi-cou2 ye-co2 | I-rigid uxinzelelo oluphezulu oluphezulu ludlulisela amandla |

| Isithuba sezinto eziphethwe njani | Igesi yegesi, kunye ne-ERVE ye-ERVE ye-PARS | I-jet yoxinzelelo lwamanzi aphezulu e-Jet iqweqwe lenkunkuma |

| Umgama phakathi kwe-nozzle kunye nempahla kunye nobuninzi bokunyamezelana | Malunga ne-0.2 "0.004 | Malunga ne-0.12 "i-0.04 |

| Ukuseta umatshini | Umthombo we-laser uhlala uhlala kumatshini ongaphakathi | Indawo yokusebenza kunye nempompo ingabekwa ngokwahlukeneyo |

| Uluhlu lweesayizi zetafile | I-8 'X 4' ukuya kwi-20 'x 6.5' | I-8 'X 4' ukuya kwi-13 'x 6.5' |

| Imveliso eqhelekileyo ye-beam kwi-Worpiece | I-1500 ukuya kwi-2600 yatts | I-4 ukuya kwi-17 Kilowatts (i-4000 bar) |

Inkqubo yesiqhelo yenkqubo kunye nokusetyenziswa

| Isifundo | I-co2 laser | Ukusika kwamanzi |

| Inkqubo eqhelekileyo isetyenziswa | Ukusika, ukuqhuba, ukubhukuqa, ukutshata, ukwenza izinto, zelding | Ukusika, ukungabinamali, ngokwakhiwa |

| Ukunqunyulwa kwezinto ezi-3d | Kunzima ngenxa yesikhokelo se-rigid beam kunye nommiselo womgama | Okunokwenzeka ngokuyinxenye ukusukela amandla entsalela emva komsebenzi utshatyalalisiwe |

| Izixhobo ezikwaziyo ukusikwa yinkqubo | Zonke izinyithi (ngaphandle kwezinyithi ezibonakalisa kakhulu), zonke iiplasitiki, iglasi, kunye neenkuni zingasikwa | Zonke izixhobo zinokuncitshiswa yile nkqubo |

| Indibaniselwano yezinto | Izixhobo ezinamanqaku ahlukeneyo anyibilikisi azinakunqunyulwa | Kunokwenzeka, kodwa kukho ingozi yokulibaziseka |

| Izakhiwo zesandwich ezinemigangatho | Oku akunakwenzeka nge-cop | Ubuchule obulinganiselweyo |

| Izinto zokusika ngofikelelo oluhonjisiweyo okanye olungalunganga | Kunqabile ukuba kwenzeke umgama omncinci kunye nentloko enkulu yokucheba | Ilinganiselwe ngenxa yomgama omncinci phakathi kwe-nozzle kunye nento |

| Iipropathi zezinto ezisikiweyo ezinokuthi zenzeke | Iimpawu zokufunxa izinto zezinto ezikwi-10,6m | Ubunzima bomzimba yinto ephambili |

| Ubuninzi bezinto ezibonakalayo apho ukusika okanye ukuqhubekisa kuqoqosho | ~ 0.12 "ukuya kwi-0.4" kuxhomekeke kwimpahla | ~ 0.4 "ukuya kwi-2.0" |

| Izicelo eziqhelekileyo zale nkqubo | Ukusika kweliti lephepha eliyisihlahla le-medium yobuninzi bendlela yokuqhubela phambili kwephepha | Ukusika ilitye, i-ceramics, kunye neentsimbi zobukhulu obukhulu |

Utyalomali lokuqala kunye neendleko zokusebenza

| Isifundo | I-co2 laser | Ukusika kwamanzi |

| Utyalomali lokuqala olufunekayo | $ 300,000 ngempompo engama-20 kWW, kunye ne-6.5 'x 4' yetafile | $ 300,000 + |

| Iinxalenye eziza kunxiba | Iglasi ekhuselayo, igesi I-nozzles, kunye nothuli kunye neefilitha zexabiso | I-jet yamanzi i-Get Nozzle, egxile i-nozzle, kwaye zonke izinto zoxinzelelo eziphezulu ezinjengeevalve, iimpuphu, kunye namatywina |

| Ukusetyenziswa kwamandla ophakathi kwenkqubo yokusika ngokupheleleyo | Thatha i-pro3 ye-watser ye-1500: Ukusetyenziswa kwamandla oMbane: I-24-40 kw Irhasi ye-laser (CO2, N2, Yewe): I-2-16 l / h Ukusika igesi (O2, N2): I-500-2000 l / h | Thatha impompo engama-20 kWW: Ukusetyenziswa kwamandla oMbane: 22-35 kw Amanzi: 10 l / h I-Ebrasive: 36 kg / h Ukuchithwa kwenkunkuma enqumlayo |

Ukuchaneka kwenkqubo

| Isifundo | I-co2 laser | Ukusika kwamanzi |

| Ubuncinci besayizi ye-slit yokusika | I-0.006 "kuxhomekeke kwisantya sokusika | 0.02 " |

| Ukunqunyulwa komphezulu | Ukunqunyulwa komhlaba kuya kubonisa ubume obuthile | Umphezulu osikiweyo uya kubonakala ngathi unesanti-ityhubhu, kuxhomekeka kwisantya esisikiweyo |

| Inqanaba lemiphetho yokusika ukuya ngokupheleleyo | Kulungile; ngamanye amaxesha iya kubonisa imiphetho | Kulungile; Kukho ifuthe "elisiphosiweyo" kwiijika zemeko yezinto ezinamatyala |

| Ukunyamezelana | Malunga ne-0.002 " | Malunga ne-0.008 " |

| Isidanga sokutsisa kwi-cut | Kuphela ukuthuka | Akukho buthathaka |

| Uxinzelelo lwe-thermal yezinto | Ukulahlekiswa, iinguqu kunye nolwakhiwo kunye nolwakhiwo lunokwenzeka kwimeko | Akukho xinzelelo lwe-thermal lwenzeka |

| Ikhosi esebenza kwizinto ezikwindlela yegesi okanye ijet yamanzi ngexesha lokuqhutywa | I-Parses Iingxaki zincinci Umsebenzi wokusebenza, umgama ayinakugcinwa | Iphezulu: I-Trie, amalungu amancinci anokuthi aqhubekiswe kuphela kwinqanaba elincinci |

Ukuqwalaselwa kukhuseleko kunye nendawo yokusebenza

| Isifundo | I-co2 laser | Ukusika kwamanzi |

| Ukhuseleko lomntuIimfuno zeZixhobo | Ukukhusela i-Laser yoKhuseleko lwe-Laser ayimfuneko ngokupheleleyo | Iiglasi zokhuseleko ezikhuselayo, ukhuseleko lweendlebe kunye nokukhusela ngokuchasene nonxibelelwano ne-jet ephezulu yamanzi aphezulu iyafuneka |

| Ukuveliswa komsi kunye nothuli ngexesha lokusebenza | Kuyenzeka; Iiplasitiki kwaye ezinye izabelo zensimbi zinokuvelisa iigesi eziyityhefu | Ayisebenzi kwi-jet yamanzi |

| Ungcoliseko lwengxolo kunye nengozi | Isezantsi kakhulu | Ngokungaqhelekanga |

| Iimfuneko zokucoca oomatshini ngenxa yokuqhubela phambili ukungcola | Icocekile | Icocekile |

| Ukusika inkunkuma eveliswa yinkqubo | Ukusika inkunkuma ikakhulu kukwimo yothuli efuna ukuthotyelwa kwe-vacuum kunye nokucoca | Isixa esikhulu senkunkuma esisikiweyo senzeka ngenxa yokuxuba amanzi kunye ne-arasives |