Ukusetyenziswa komatshini wokusika we-Stainless Steel Laser kwi-Decoration Engineering Industry

Insimbi engenasici isetyenziswa kakhulu kushishino lobunjineli bokuhombisa ngenxa yokumelana nokugqwala okuqinileyo, iipropathi eziphezulu zoomatshini, ukungaguquguquki komphezulu wexesha elide, kunye nemibala eyahlukeneyo yokukhanya ngokuxhomekeka kwi-engile yokukhanya. Umzekelo, ekuhombiseni iiklabhu ezahlukeneyo ezikumgangatho ophezulu, iindawo zokuzonwabisa zikawonke-wonke, kunye nezinye izakhiwo zasekhaya, isetyenziswa njengesixhobo samakhethini, iindonga zeholo, imihombiso yelifti, iintengiso zemiqondiso, kunye nezikrini zedesika yangaphambili.

Nangona kunjalo, ukuba iipleyiti zensimbi ezingenasici kufuneka zenziwe kwimveliso yensimbi engenasici, ngumsebenzi onzima kakhulu wobugcisa. Iinkqubo ezininzi ziyafuneka kwinkqubo yokuvelisa, njengokusika, ukugoba, ukugoba, ukuwelda, kunye nokunye ukusetyenzwa koomatshini. Phakathi kwabo, inkqubo yokusika yinkqubo ebalulekileyo. Kukho iintlobo ezininzi zeendlela zokucutshungulwa kwensimbi engenasici, kodwa ukusebenza kakuhle kuphantsi, umgangatho wokubumba umbi kwaye awufane uhlangabezane neemfuno zemveliso yobuninzi.

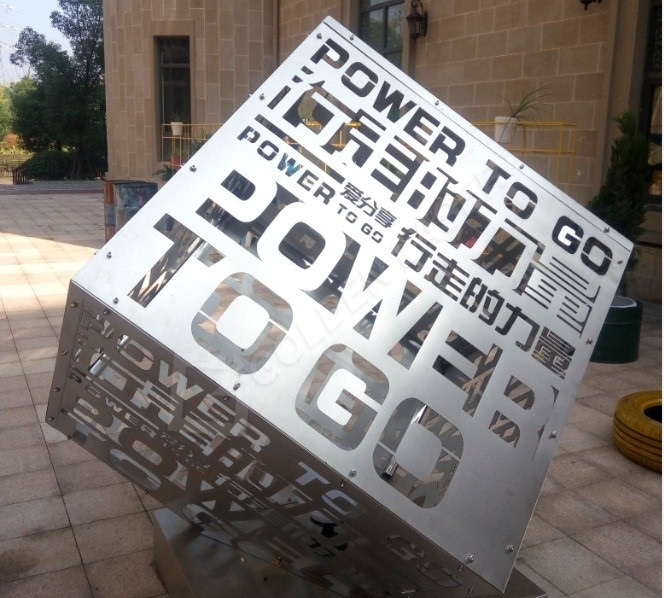

Ngoku,iimatshini zokusika zensimbi ezingenasicizisetyenziswa kakhulu kumzi mveliso wesinyithi ngenxa yomgangatho wazo olungileyo weplanga, ukuchaneka okuphezulu, ii-slits ezincinci, iindawo ezisikiweyo ezigudileyo, kunye nokukwazi ukusika ngokulula imizobo engafanelekanga. Ishishini lobunjineli bokuhombisa alikho. Jonga ukusetyenziswa komatshini wokusika i-laser yensimbi engenasici kwishishini lokuhlobisa.