Thumela Uphenyo ukuze uthole ulwazi Olusha Kakhulu Lomshini Wokusika we-Robot Laser kanye Nentengo!

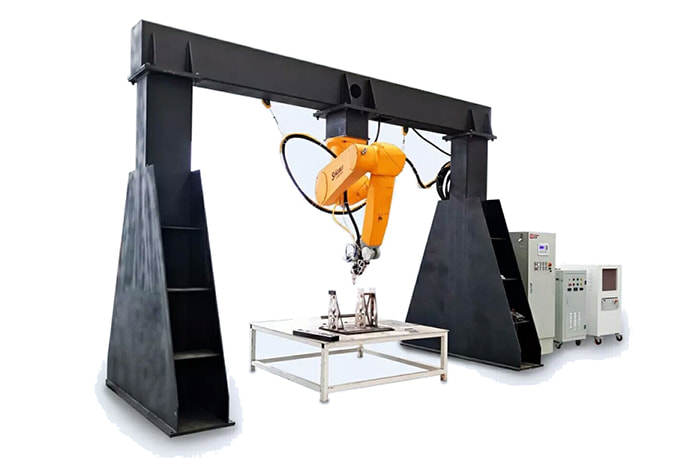

3D laser Cutting Machine

- I-Fiber Laser Cutter ene-Robotic Arm System.

I-Robot 3D Laser Cutting Machine Highlights

1. I-XR160L yenkampani yami ebeka irobhothi embonini ethile yokucubungula ishidi lensimbi, okokusebenza kwezinhlelo zamarobhothi i-Stäubli RX160L, i-IPG500W i-fiber laser, ikhanda le-laser ye-LASERMECH (okuhlanganisa umshini onyakazayo), ithebula lokubeka indawo, i-chiller, ukuphepha nezinye izingxenye eziyinhloko.

2. Ukuxhumana kwe-axis engu-6, ububanzi bomsebenzi, kuze kufike ebangeni elide, umthamo othwala umthwalo, ungaba sendaweni yokusebenza yokusika ithrekhi ye-3D

3. I-Compact, wrist slim, ngisho nasezimeni ezinzima, imikhawulo ezindaweni eziningi, isengakwazi ukufeza ukusebenza okuphezulu

4. Ijubane lenqubo kanye nokuma kungashintshwa, ukuze kuzuzwe ukunemba okungcono kakhulu kokukhiqiza, isivuno esikhulu, nesivinini esikhulu.

5. Umsindo ophansi, isikhawu sokulungisa esijwayelekile yinde, impilo ende yesevisi

6. I-manipulator ingashintshwa ngokusebenzisa itheminali ephathwayo

7. Ngokushintsha uhlelo kanye nezinguquko ze-hardware, zingafinyelela ukusika kwe-laser, i-laser welding, ukupakisha, ukuphatha kanye neminye imisebenzi.

Izici Zomshini Wokusika we-3D Laser

I-1.Umthombo we-Laser: ukusetshenziswa kwe-high-performance IPG fiber lasers, ukusebenza kahle okuphezulu, izindleko eziphansi zokusetshenziswa okuhlanganisiwe.

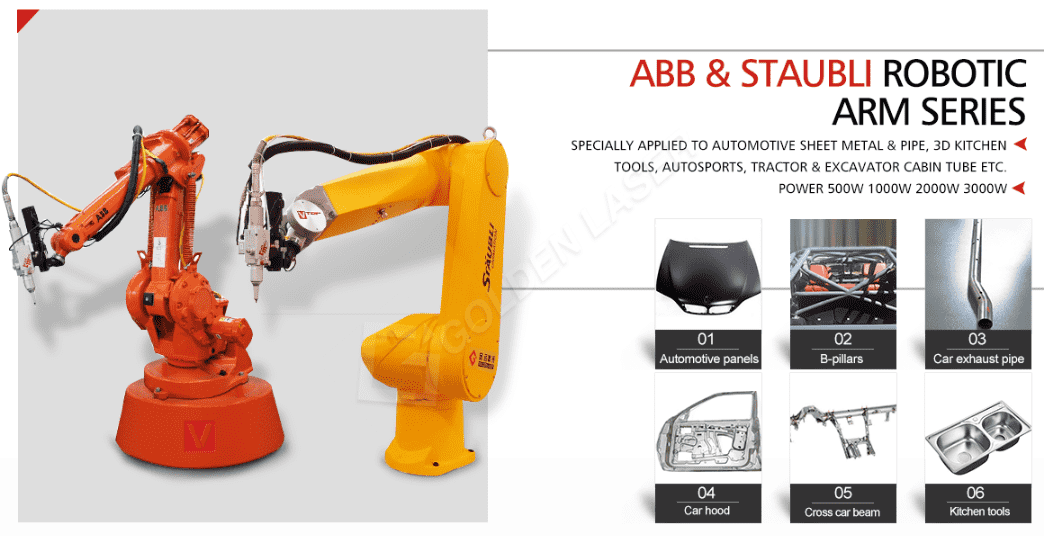

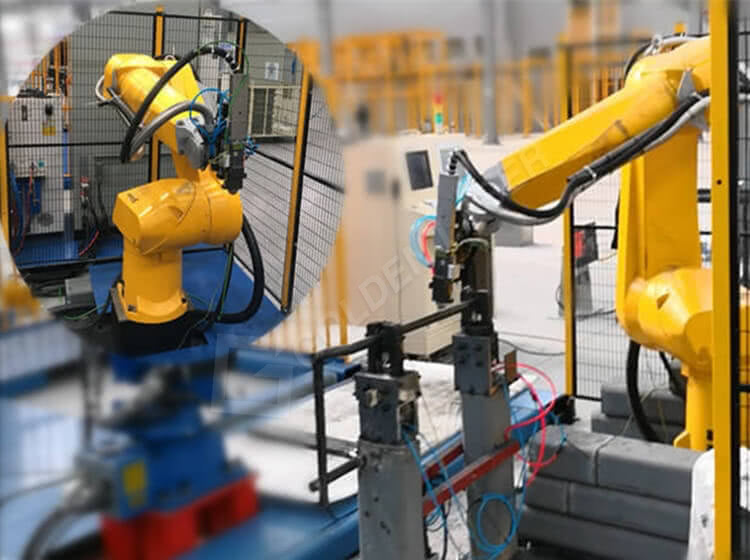

2.Ukuqaliswa kokusikwa kwe-laser kwama-ejensi asebenzisa irobhothi lase-Swiss Staubli. I-Staubli irobhothi irobhothi elinembe kakhulu embonini yamarobhothi. Ukusetshenziswa kwe-aluminium titanium alloy robot body, i-harmonic reducer design, umzimba werobhothi ohlobene nezinye izinhlobo, engasindi, isivinini esikhulu, ukunemba okuphezulu. Amarobhothi emboni ye-TL160L ekugobeni okuncane kokusikwa okuhle nefomethi enkulu ukutshela ukusika kwe-laser okuhlobene nezinye izinhlobo kunezinzuzo ezisobala. Ekusikeni kwe-laser enesivinini esikhulu, uhlelo lwamarobhothi e-Staubli lungafinyelela isivinini esingu-18 m/min ngaphandle kwe-jitter, ezinye izinhlobo azivamile ukuqinisekisa isivinini sokusika i-laser esingu-10 m/min ukuze kuqinisekiswe imiphumela emihle yokusika. Futhi ku-round-cut encane, ungakwazi ukusika ububanzi obuncane kakhulu obuyindilinga obuyi-2mm, umphumela wokusika ubushelelezi futhi omuhle, ezinye izinhlobo zamarobhothi ezimbonini ezingakwazi ukukwenza.

I-3.Irobhothi le-Staubli lingacushwa ngokuya ngezidingo zangempela zamakhasimende isofthiwe yokuhlela engaxhunyiwe ku-inthanethi, isofthiwe ingakwazi ukufunda isofthiwe yemephu yezinhlangothi ezintathu yonke indawo vda, igs, x_t, sldprt, prt, par kanye namanye amafomethi, ngqo ku-software compiler ithrekhi izinqubo, Ukufundisa, elula futhi ephumelelayo ukufeza umkhiqizo wohlobo lomsebenzi wokuhlela.

4.Landela ikhanda lokusika i-robot laser: ozikhethela ngemikhiqizo ephezulu yamazwe ngamazwe yekhanda lokusika i-laser ukuze uqinisekise ukuthi i-laser beam ihlale isesimweni sokugxila ukuze uqinisekise umphumela wokusika.

I-5.Isistimu yokuphefumula komoya: uhlelo luhlanganisa umoya ocindezelayo ophezulu, i-nitrogen, i-oksijini yesakhiwo somthombo wegesi emithathu kanye nendlela yegesi yokuguqula i-voltage ephezulu nephansi, ikhasimende lingakhetha ngokuvumelana nezidingo zekhwalithi yokucubungula kanye nezindleko zegesi elisizayo.

Uhlelo lwe-6.Lubrication: Umshini wokusika we-laser we-3d ufakwe uhlelo lokugcoba ngesandla, ukunciphisa ukugqoka kwezingxenye ezihambayo, ukuqinisekisa isivinini esikhulu somshini we-laser wezinhlelo ze-robot.

I-Robot Fiber Laser Cutting Machine Ividiyo Esebenzayo

Umshini Wokusika I-Robotic Arm 3D Laser Esizeni Sekhasimende

I-Robotic Arm 3D Laser Cutting Metal Tubes ne-Metal Sheets Sample

Ufuna Ulwazi Olwengeziwe mayelana neRobot Laser Cutter?

Isicelo Sezinto Zokusebenza Nemboni

Isebenza kuzo zonke izinhlobo zepayipi lensimbi elingalingani kanye neshidi lensimbi yokusika i-laser, efanelekayo embonini yezimoto, ukukhiqiza isikhunta, izitsha zasekhishini, imikhiqizo yensimbi, njengokusika okuzenzakalelayo.

1. Ngezembozo zensimbi yensimbi yezimoto kanye nezingxenye ze-chassis nezinye iziqephu zenani elincane lokukhiqiza, njengemakethe yokulungisa, amaloli, amabhasi, imishini yokwakha, izimoto eziguquliwe nokunye.

2. Ngokukhiqizwa okuguquguqukayo komshini wokusika we-laser, esikhundleni sokugxiviza okuvulekile, okulungele ukukhiqizwa komuntu siqu, kodwa futhi kufinyeze umjikelezo wokuthuthukiswa komkhiqizo, ukuphendula okusheshayo emakethe.

3. Ngesistimu yokusika i-robot laser, esikhundleni sokusika i-plasma ngesandla, yenza kube lula kakhulu inqubo, kodwa futhi iye yahlushwa izisebenzi ze-plasma zomkhiqizi ekulawuleni inkinga.

4. Isamba sezindleko eziphansi zemishini, ukusetshenziswa kwezindleko eziphansi, ukusebenza kahle okuphezulu, okunye ukungeniswa kwamanye amazwe komshini wokusika we-laser we-axis emihlanu, ukonga okubalulekile ezindlekweni zomsebenzi ngamunye.

5. Ifanele imboni yokusingatha esekela ukunikezwa kwenqwaba yasekuqaleni, neminye imikhiqizo yokwandisa umthamo wokukhiqiza ngemva kokugxivizwa kwesikhunta, ukuthuthukiswa kwesikhunta ukunciphisa ingozi yokutshala izimali.

Machine Technical Imingcele

I-ABB2400 Robotic Arm Main Imingcele Yezobuchwepheshe

| Inombolo yezimbazo zerobhothi | 6 | Umthwalo we-eksisi wesithupha | 20Kg |

| I-robotic crane | 1.45m | Indawo ephindaphindiwe | 0.05mm |

| Isisindo | 380Kg | Amandla kagesi | 200-600V, 50/60Hz |

| Ukusetshenziswa kwamandla | 0.58kw | amandla alinganiselwe | 4KVA/7.8KV |

| I-ABB 2400 Robot gantry cutting machine imingcele yezobuchwepheshe | |||

| Ipharamitha iyonke yemishini | |||

| Isikhala saphansi(mxm) | cishe 3 * 4.2 (okuhlanganisa ama-chiller kanye nesistimu yokomisa komoya enengcindezi ephezulu) | ||

| Ukuphakama okusebenzayo | 350mm | Umsindo | <65 Db(akubandakanyi ifeni yokukhipha umoya) |

| Izidingo zokuphakelwa kwamandla | I-AC220V±5% 50HZ (Simplex) | Amandla aphelele | 4.5KW (Ngaphandle kokukhipha umoya) |

| Izidingo zemvelo | Ibanga lokushisa: 10-35 ℃ Ibanga lokuswakama: 40-85% 1000 amamitha ngaphansi kwezinga lolwandle, ukusetshenziswa kwemvelo ngaphandle kokuvutha, ukuqhuma, magnetic enamandla, ukuzamazama komhlaba okunamandla | ||

| Imingcele eyinhloko yomthombo we-laser | |||

| Uhlobo lwe-laser | I-fiber laser | ||

| Ama-Lasers ayasebenza | Okuqhubekayo / ukuguquguquka | Amandla e-laser | 700W (1000w 2000w 3000w inketho) |

| Imodi yendawo | Imodi eminingi | Laser wavelength | 1070nm |

| Uhlelo olusizayo | |||

| Isistimu yokupholisa | Iphampu yephampu enamazinga okushisa akabili enokushisa kwesistimu yokuhlanza (ukucushwa okuyingqayizivele) | ||

| Isistimu yokupholisa yomthombo we-laser | I-air conditioning engu-350W evundlile (ukucushwa okuyingqayizivele) | ||

| Uhlelo lwegesi elisizayo | Imithombo emithathu yegesi yokucindezela okukabili (ukucushwa okuyingqayizivele) | ||

| Ikhanda lokusika i-laser | Ukugxila kokulandelela okunamandla | ||

Imikhiqizo ehlobene

-

I-RN16 / RN18 / RN26 (ABB X2400D/X2400L / Staubli XR160L)

Multifunction 3D Robot Laser Cutting Machine For Metal Sheet Futhi Metal Tube Cut -

I-VR16 / VR18 / VR24

I-Fiber Laser Robot Arm 3D Cutting Tube kanye nePipe For Auto Parts -

RE16/RE18/RE26

Iseli Lomshini Wokusika Irobhothi Laser